Support beam device for fixing boiler furnace water wall

A boiler furnace and water-cooled wall technology, which is applied to steam boiler components, steam boilers, steam boiler accessories, etc., can solve the problems of irregular shape of water-cooled wall structure, inability to guarantee construction quality, less construction workload, etc., and achieve improvement Construction efficiency, simple structure, and the effect of ensuring construction quality and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

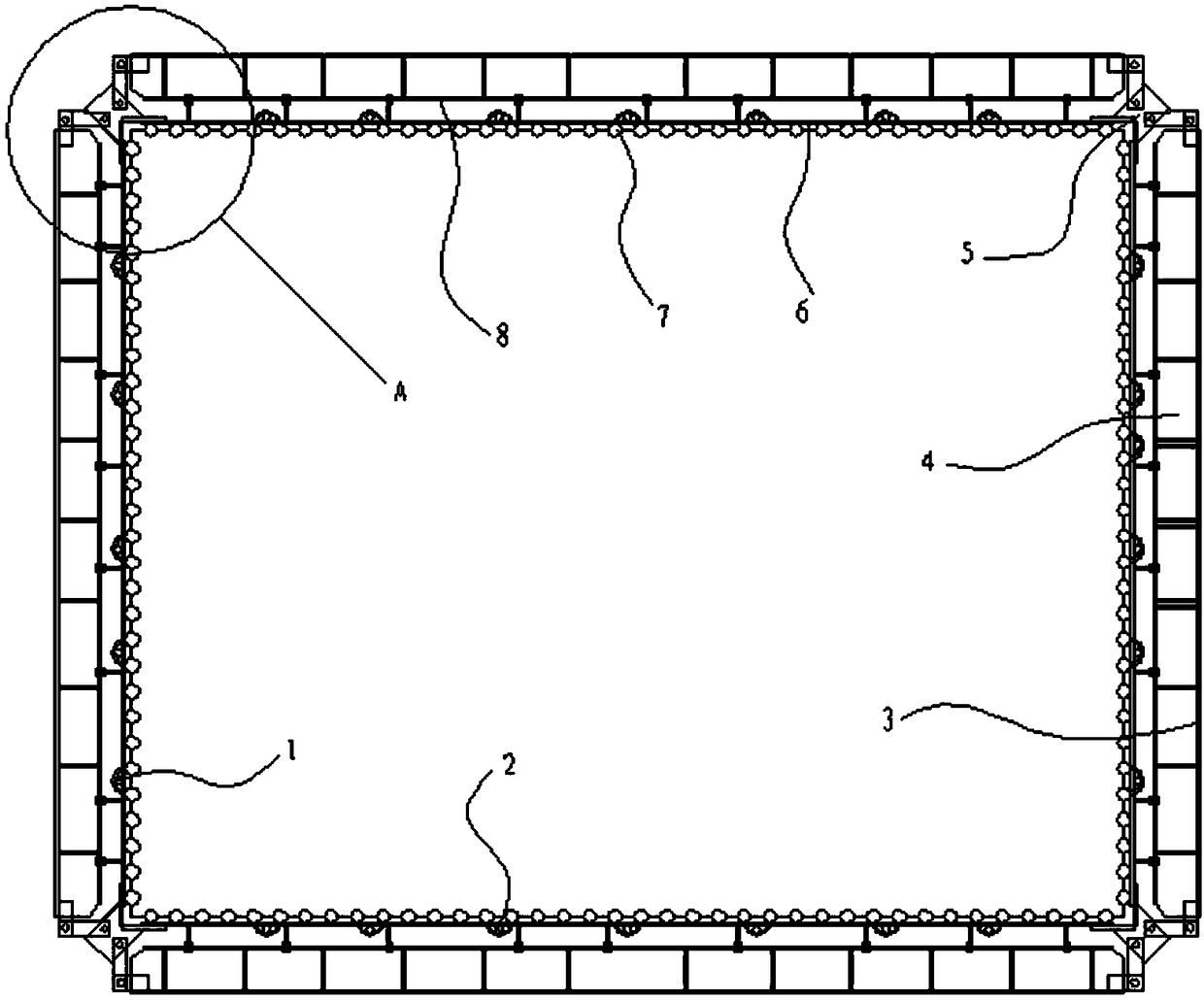

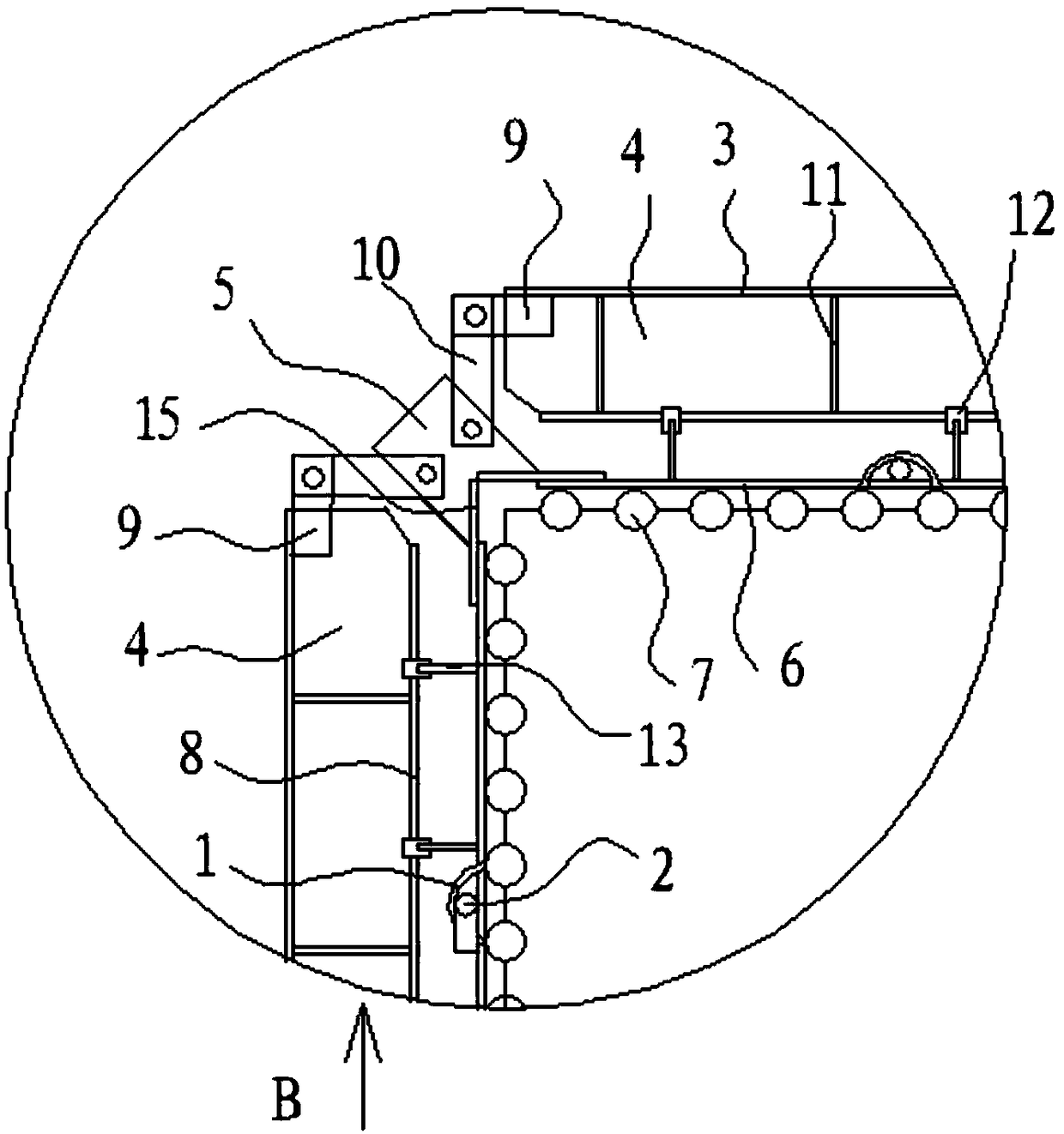

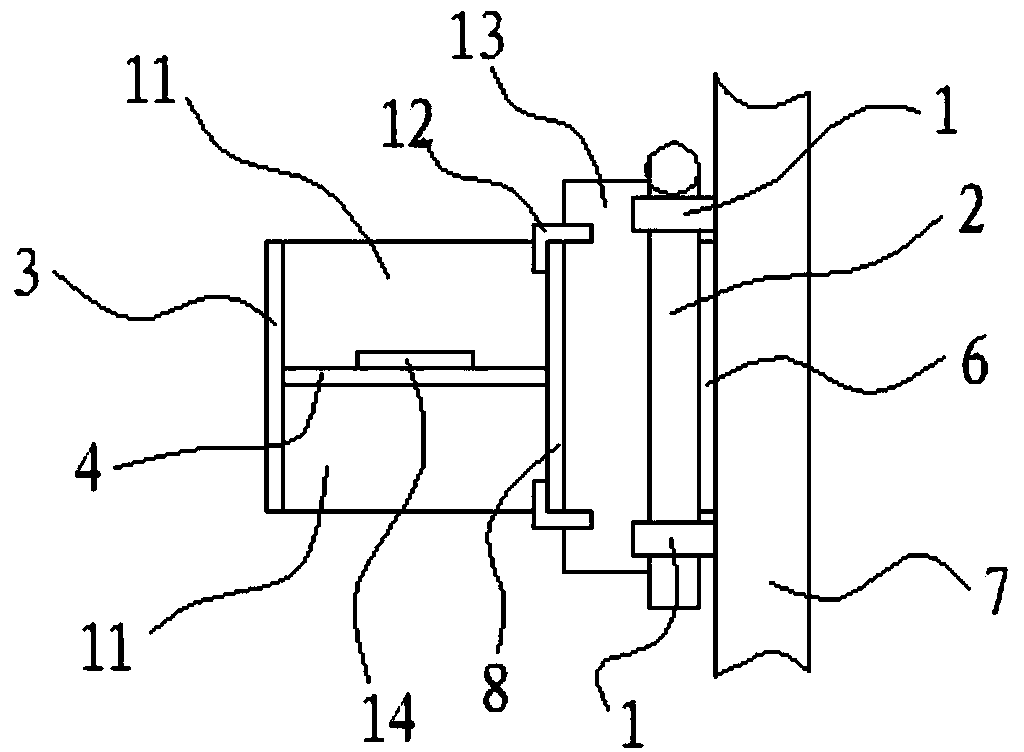

[0015] Embodiment 1: as attached Figure 1~3 As shown, a support beam device for fixing the water-cooled wall of the boiler furnace includes a water-cooled wall tube 7, and several water-cooled wall tubes 7 are connected by fins to form a square structure, and four pads are pasted around the outer sides of the water-cooled wall tube 7 The outer side of the plate 6 and the backing plate 6 are fixedly connected with several vertical ribs-13, and the outer side of the ribs-13 is fixedly connected with two L-shaped fasteners 12 which are up and down symmetrical, and a bottom plate is arranged between the fasteners 12 8. The outer side of the bottom plate 8 is fixedly connected with the panel 3 through the horizontal connecting plate 4, and the extension plate 15 is fixedly connected with the outer sides of the two ends of the backing plate 6, and the outer sides of the two adjacent extension plates 15 are fixedly connected with horizontal fixing plates. The plate 5 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com