Centrifugal pump radial sealing ring with cylindrical guide vanes

A technology of guide vanes and radial seals, which is applied to parts, pumps, and pump elements of pumping devices used for elastic fluids, and can solve problems affecting the hydraulic performance of the impeller, unfavorable processing and assembly, and complex processing technology. Improve performance, reduce processing and assembly difficulty, and simplify replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

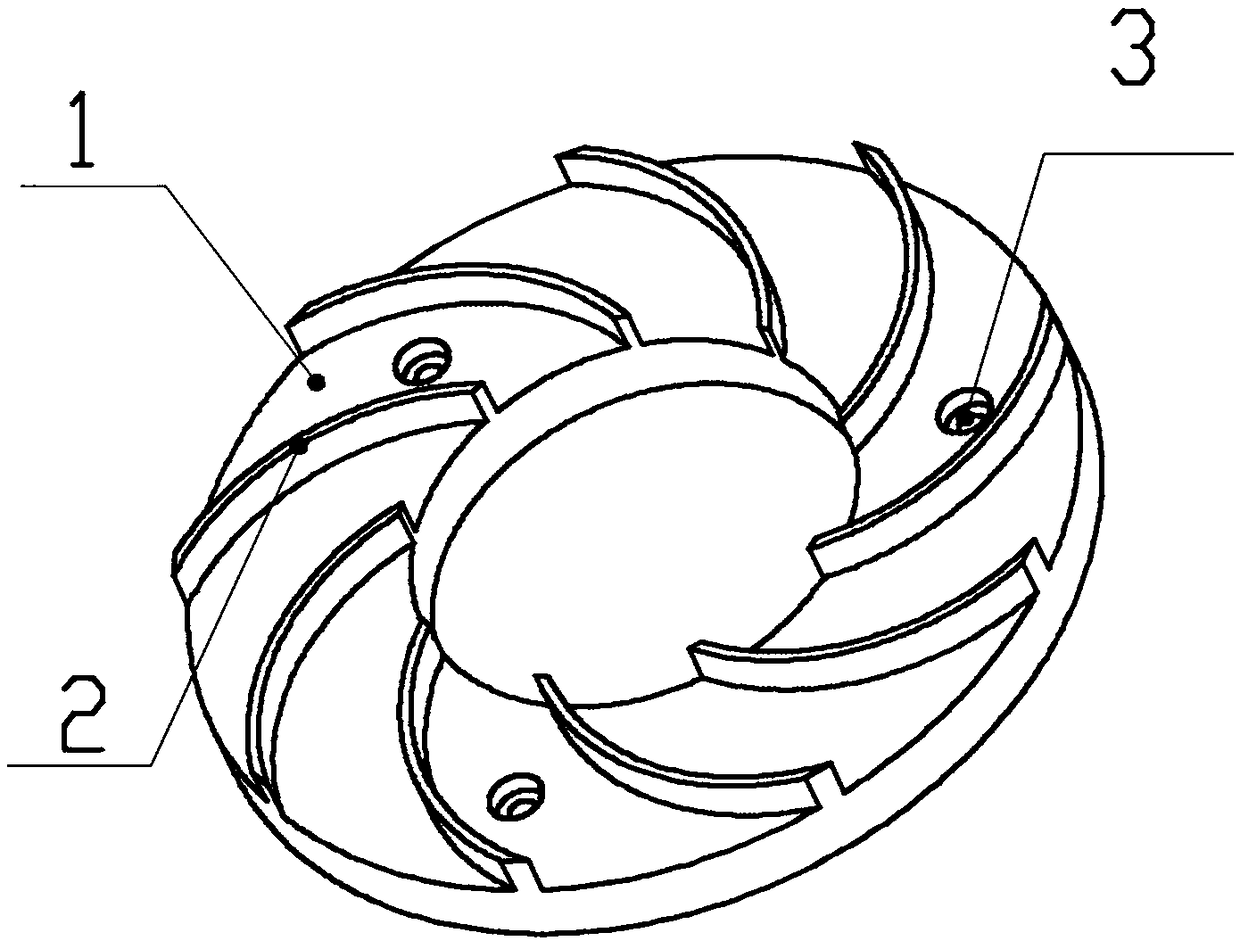

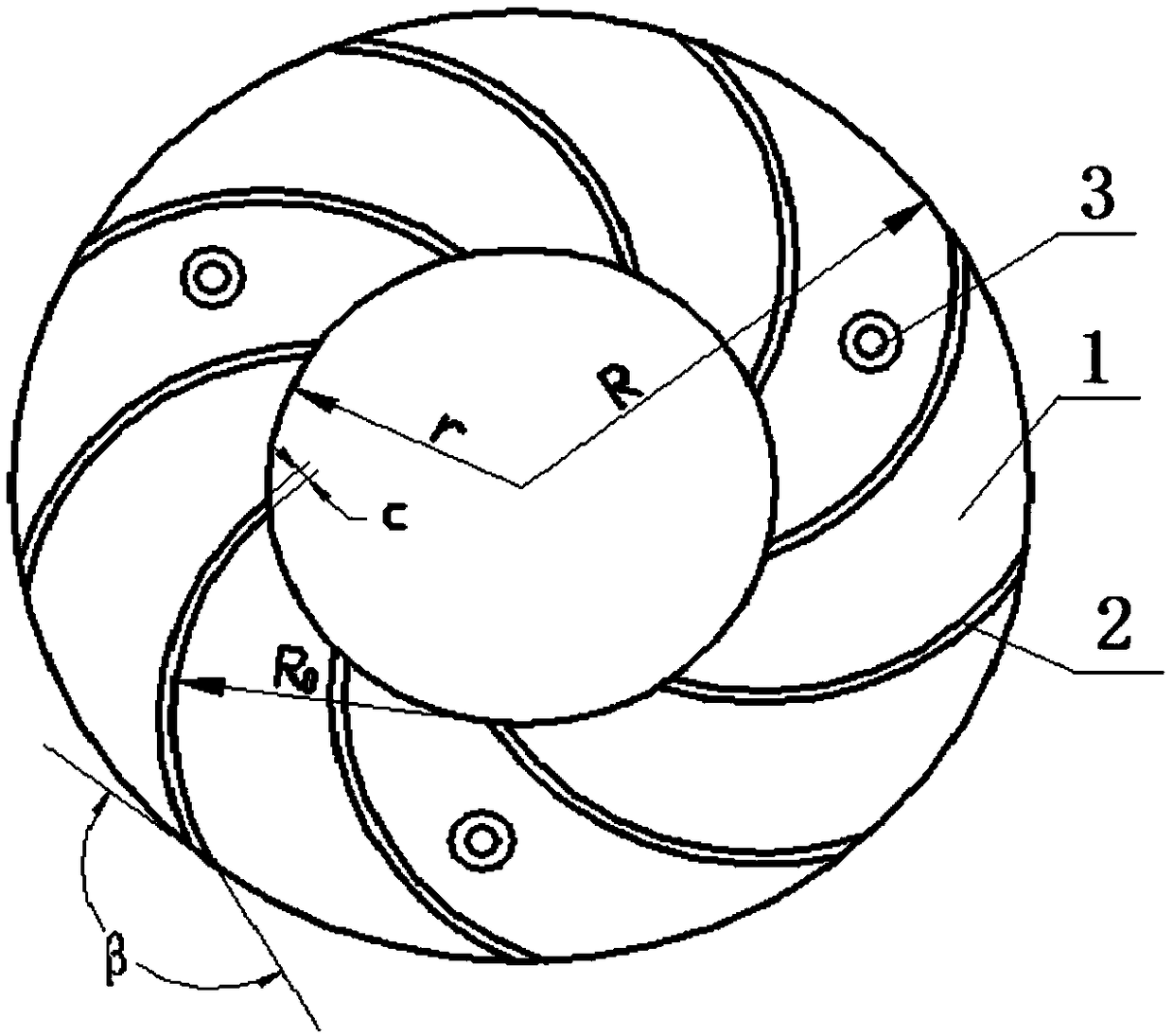

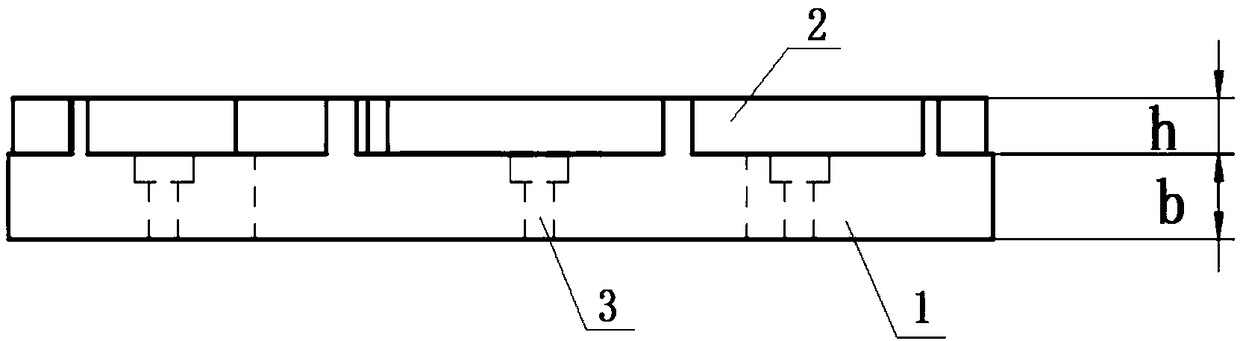

[0020] see Figure 1-2 As shown, the present invention is made up of disc 1 and radial guide vane 2, and the middle of disc 1 has a central through hole. A plurality of radial guide vanes 2 are evenly and fixedly arranged along the circumferential direction on one side of the disc 1 , and the radial guide vanes 2 protrude axially from the disc surface of the disc 1 . Each radial guide vane 2 is a cylindrical plate, and the central axis of the cylindrical plate is perpendicular to the disc surface of the disc 1 . Several countersunk screw holes 3 are processed on the surface of the disc 1 for fixing the disc 1 .

[0021] see Figure 4 and Figure 5 , the present invention is installed between the volute 4 and the impeller 5 of the centrifugal pump. When installing, the central axis of the disc 1 is required to be in line with the central axis of the impeller 5. Fixedly connected to the volute 4, the radial guide vane 2 faces the impeller 5, and the radial guide vane 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com