Supercritical/trans-critical carbon dioxide combined cycle power generation system for internal combustion engine waste-heat utilization

A carbon dioxide, cycle system technology, used in machines/engines, internal combustion piston engines, combustion engines, etc., can solve the problem of increasing the complexity and overall size of the combined cycle system, increasing the pressure of carbon dioxide and organic working fluid, and reducing the combined cycle power generation, etc. problems, to achieve the effect of reducing the overall size, improving utilization efficiency, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

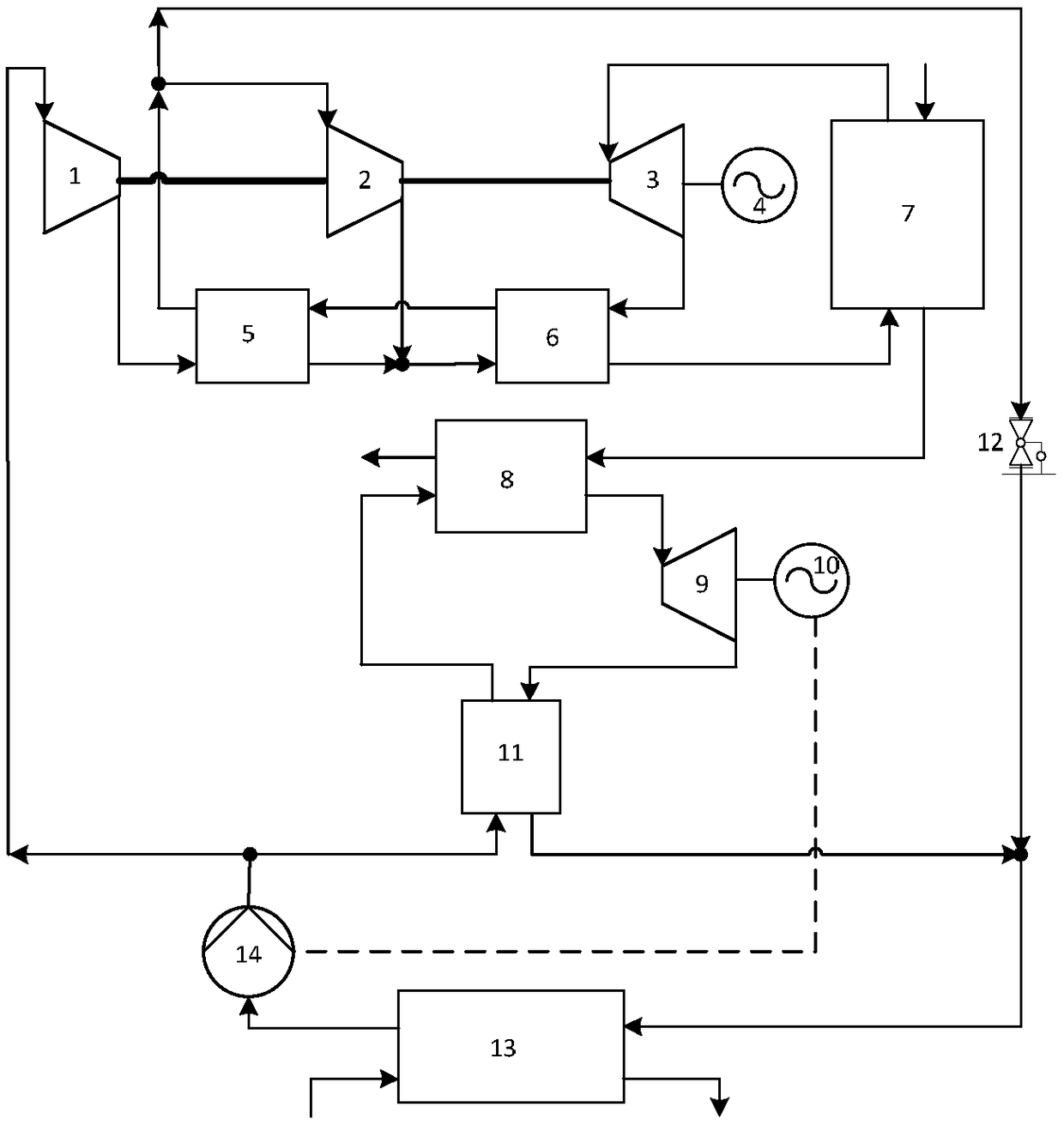

[0018] Such as figure 1 As shown, a supercritical / transcritical carbon dioxide combined cycle power generation system utilizing waste heat from an internal combustion engine of the present invention includes a high-temperature heat source heat exchanger 7, a low-temperature heat source heat exchanger 8, a pressure reducing valve 12, a condenser 13, and a working medium pump 14. Supercritical carbon dioxide recompression Brayton cycle system and transcritical carbon dioxide Rankine cycle system; liquid carbon dioxide enters the working medium pump 14 from the condenser 13 and is compressed into a supercritical gas, and then the compressed carbon dioxide gas enters the working medium pump 14 The outlet of 14 is divided into two branches: one of them is used as the working medium of the transcritical carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com