Pneumatic shield gate dam

An air shield and shield plate technology, applied in the field of air shield dams, can solve problems such as incoordination, accelerated aging of rubber airbags and limit bands, deformation of bolt holes, etc., achieving ingenious structural design, improved safety, and durability good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

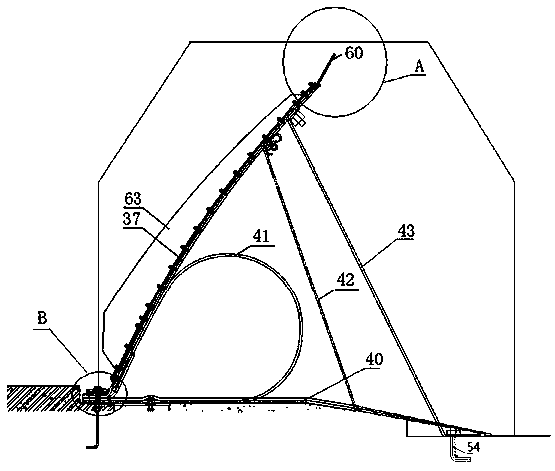

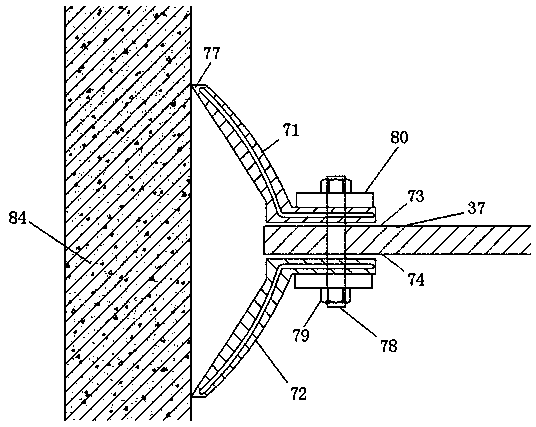

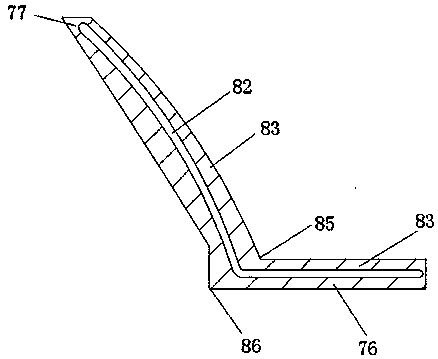

[0066] For the gas shield dam of this embodiment, refer to the attached Figure 1-25The air shield dam of this embodiment includes a shield 37 whose bottom is fixed on the base plate 40. The back of the shield 37 is sequentially provided with an airbag 41 for driving the shield 37 up and down from front to back, and is used to cover the airbag 41 and has The ornamental curtain 43, the left and right sides of the shield plate 37 are provided with wall panels, and the left and right sides of the shield plate 37 and the corresponding wall panels are provided with a two-way side wall waterstop body group, The bottom of the shield plate 37 is connected to the foundation base plate 40 through the foundation flexible connection belt, and the top of the shield plate 37 is installed with a spoiler.

[0067] Among them, the two-way side wall waterstop includes two two-way sidewall waterstop body groups installed on the left and right sides of the shield plate 37, and the two two-way sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com