Method for producing biogas from straw

A technology for straw and biogas, applied in the field of straw utilization, can solve the problems of low gas production efficiency, unstable gas production, low straw conversion efficiency, etc., and achieve the effects of improving work efficiency, avoiding blockage and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

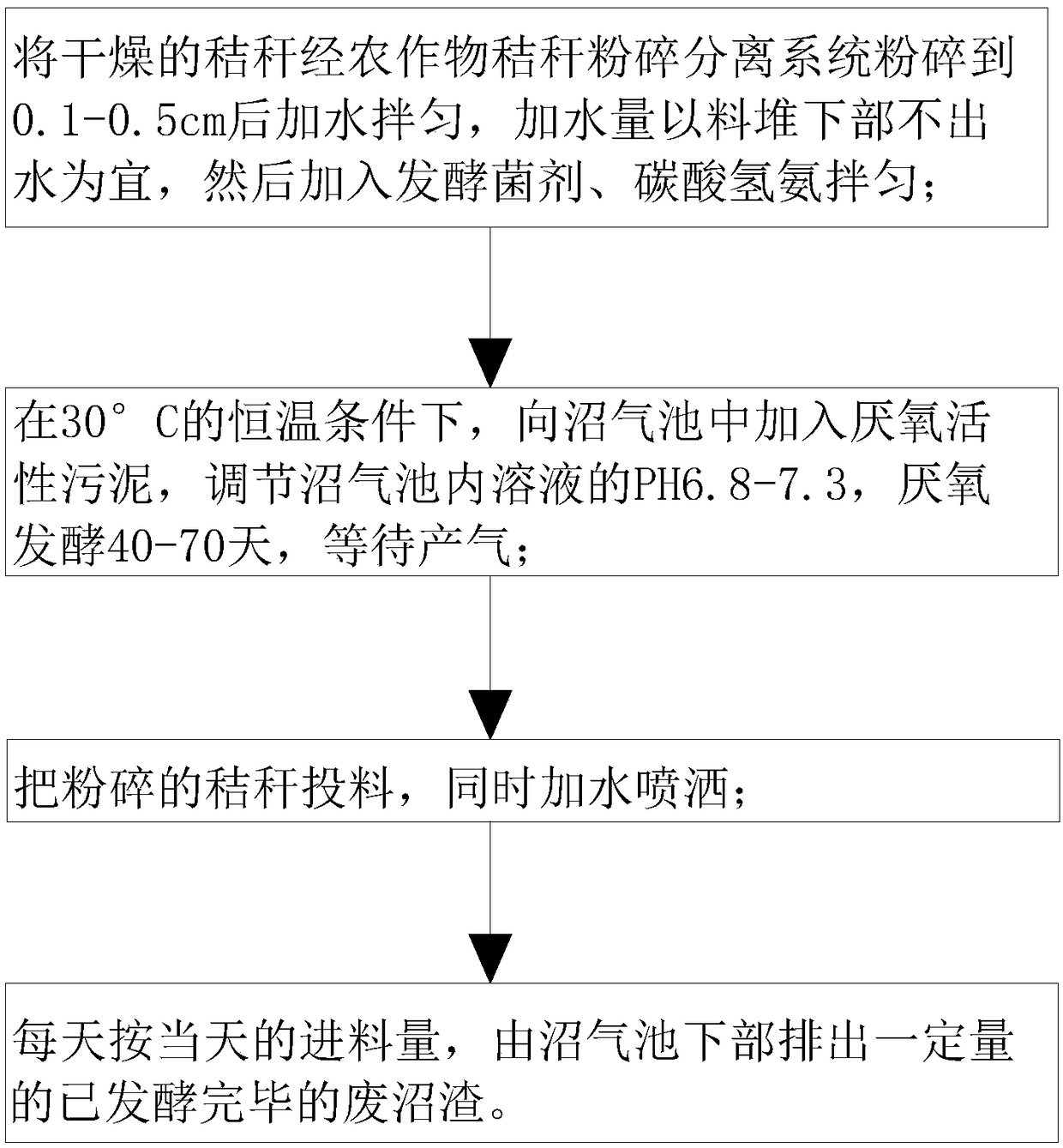

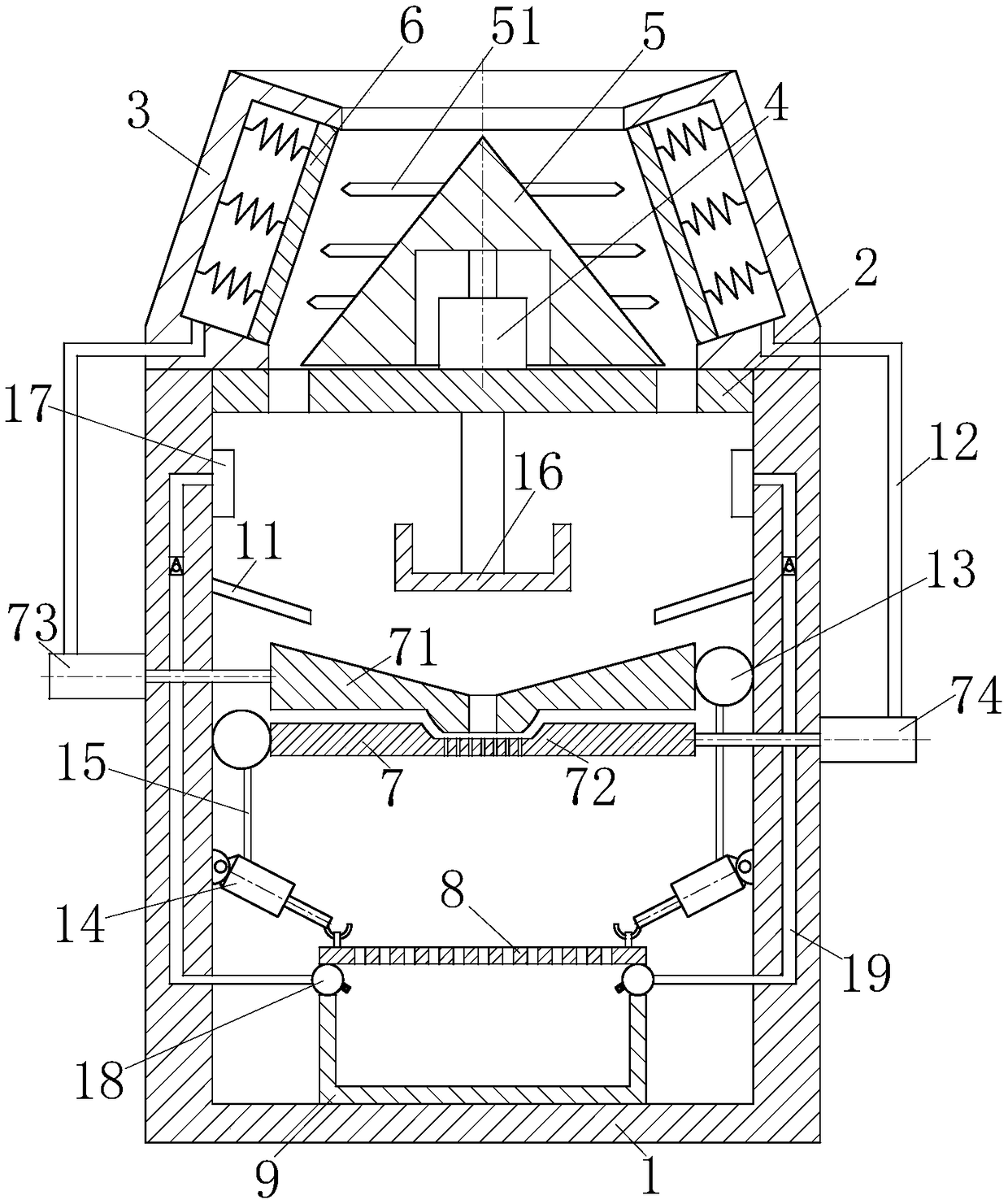

[0023] use Figure 1-Figure 2 A method for producing biogas from straw according to an embodiment of the present invention is described as follows.

[0024] Such as figure 1 and figure 2 As shown, a method for producing biogas from straw according to the present invention, the method comprises the following steps:

[0025] Step 1: Grinding the dry straw to 0.1-0.5cm by the crop straw crushing and separation system, adding water and mixing well, the amount of water added should be such that water does not come out from the lower part of the stockpile, then adding fermentation bacteria agent and ammonium bicarbonate and mixing well;

[0026] Step 2: After mixing well in step 1, add anaerobic activated sludge to the biogas digester at a constant temperature of 30°C, adjust the pH of the solution in the biogas digester to 6.8-7.3, anaerobically ferment for 40-70 days, and wait for the production gas;

[0027] Step 3: After the gas is produced in Step 2, feed the crushed straw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com