A kind of preparation method of camellia oil

A technology of camellia oil and camellia seed, which is applied in the field of edible oil processing, can solve the problems of not being able to produce high-end products, achieve the effects of improving edible performance, clear process parameters, and mild refining conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

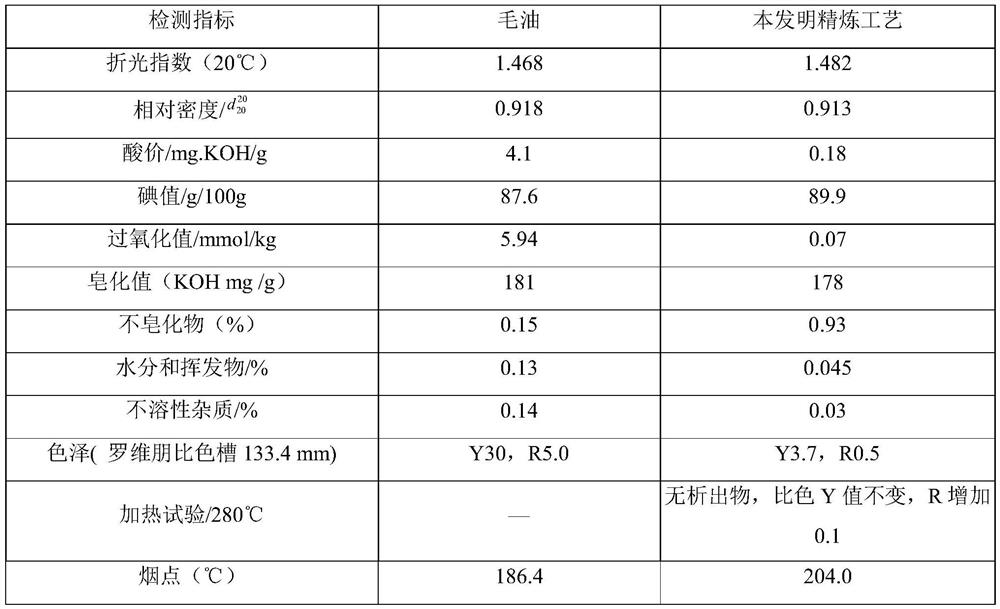

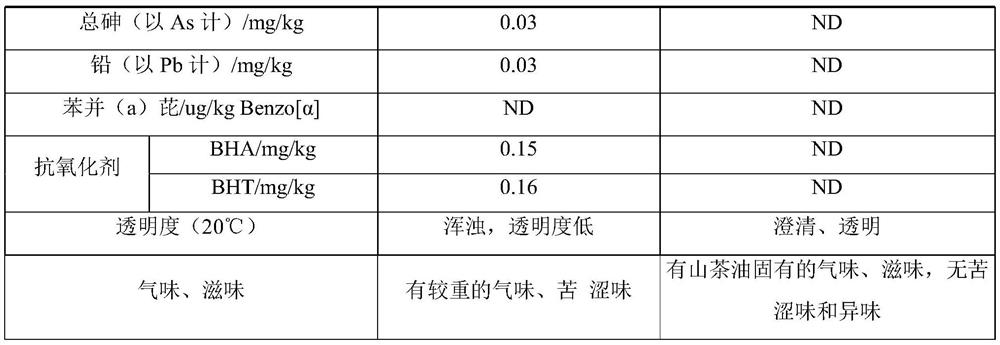

Examples

Embodiment 1

[0030] A preparation method of camellia oil, comprising the following steps:

[0031] a) Crude oil pressing: pressing and filtering camellia seeds with a water content of 5% at 80° C. to obtain pressed crude oil, the impurity content of which is less than 0.3 wt %;

[0032] b) Deacidification: adding sodium bicarbonate of 0.1 times the weight of the degummed oil to the pressed crude oil, then stirring and deacidifying at a speed of 10 rpm at 70° C. for 30 minutes, and then centrifuging to remove the precipitate to obtain the deacidified oil;

[0033] c) Degumming: Add 3 times the volume of squeezed crude oil to the deacidified oil at 30°C, then stir at 70rpm for 15 minutes at 30°C, then stir at 20rpm for 5 minutes, then stand at 25°C After 4 hours, degummed oil was obtained after sedimentation and separation to remove impurities and water;

[0034]d) Decolorization and deodorization: heat the degummed oil to 50°C, add activated clay of 3wt% degummed oil weight and modified ba...

Embodiment 2

[0039] A preparation method of camellia oil, comprising the following steps:

[0040] a) Crude oil pressing: pressing and filtering camellia seeds with a water content of 6% at 85° C. to obtain pressed crude oil, the impurity content of which is less than 0.3 wt %;

[0041] b) Deacidification: adding sodium bicarbonate 0.15 times the weight of the degummed oil to the pressed crude oil, then stirring and deacidifying at a speed of 15 rpm at 80° C. for 35 minutes, and then centrifuging to remove the precipitate to obtain the deacidified oil;

[0042] c) Degumming: Add 4 times the volume of squeezed crude oil to the deacidified oil at 35°C, then stir at 75rpm for 17 minutes at 35°C, then stir for 6 minutes at 25rpm, then stand at 28°C After 4.5 hours, degummed oil was obtained after sedimentation and separation to remove impurities and water;

[0043] d) Decolorization and deodorization: heat the degummed oil to 52°C, add activated clay of 3.5wt% degummed oil weight and 1.3 time...

Embodiment 3

[0048] A preparation method of camellia oil, comprising the following steps:

[0049] a) Crude oil pressing: pressing and filtering camellia seeds with a water content of 7% at 90°C to obtain pressed crude oil, the impurity content of which is less than 0.3wt%;

[0050] b) Deacidification: adding sodium bicarbonate 0.2 times the weight of the degummed oil to the pressed crude oil, then stirring and deacidifying at a speed of 20 rpm at 90° C. for 40 minutes, and then centrifuging to remove the precipitate to obtain the deacidified oil;

[0051] c) Degumming: Add water at 40°C that is 5 times the volume of the pressed crude oil to the deacidified oil, then stir at 40°C at a speed of 80rpm for 20 minutes, then stir at a speed of 30rpm for 8 minutes, and then stand at 30°C After 5 hours, degummed oil was obtained after sedimentation and separation to remove impurities and water;

[0052] d) Decolorization and deodorization: heat the degummed oil to 55°C, add activated clay of 4wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com