Repairing putty with quick drying under normal temperature

A putty, room temperature technology, applied in the direction of filling slurry, etc., can solve the problems of poor surface quality of the coated layer, long drying time, and difficulty in thick coating, and achieve the effect of meeting the requirements of thick coating, simple manufacturing process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

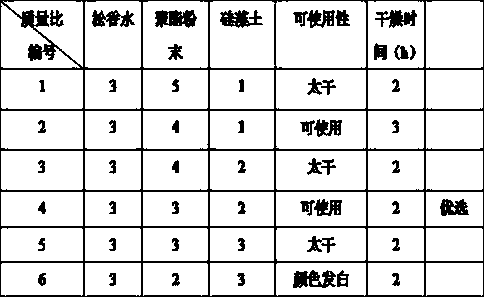

Examples

Embodiment 1

[0035] A kind of normal temperature quick-drying repair putty of the present embodiment, this putty is prepared by mixing pine water, polyester powder and diatomite, wherein, the mass ratio of pine water, polyester powder and diatomite is 3:3: 2. And the polyester powder is composed of saturated polyester resin, titanium dioxide, curing agent, degassing agent, leveling agent, wetting accelerator, barium sulfate and pigments, and each component in the polyester powder is composed of the following mass percentages: saturated poly 60% ester resin, 20% titanium dioxide, 3% curing agent, 1% degassing agent, 2% leveling agent, 1% wetting accelerator, 10% barium sulfate, and 3% pigment.

[0036] The particle size of the polyester powder in this example is 32 μm to 42 μm. It should be noted that if the particle size of the polyester powder is too large, larger particles will be formed, resulting in poor surface quality of the coated layer; if the polyester powder The particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com