Glucosylglycerol product as well as purification method and application of glucosylglycerol

A technology of glucoside and glucose, which is applied in the field of compound purification, can solve the problems of low purity and yield, and cannot be industrialized, and achieves the effects of low production cost, easy operation and control, and reduction of impurity components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] A culture method for obtaining high-content GG algae cells, comprising the following steps:

[0147] (1) Obtain the cultured algae cell stage:

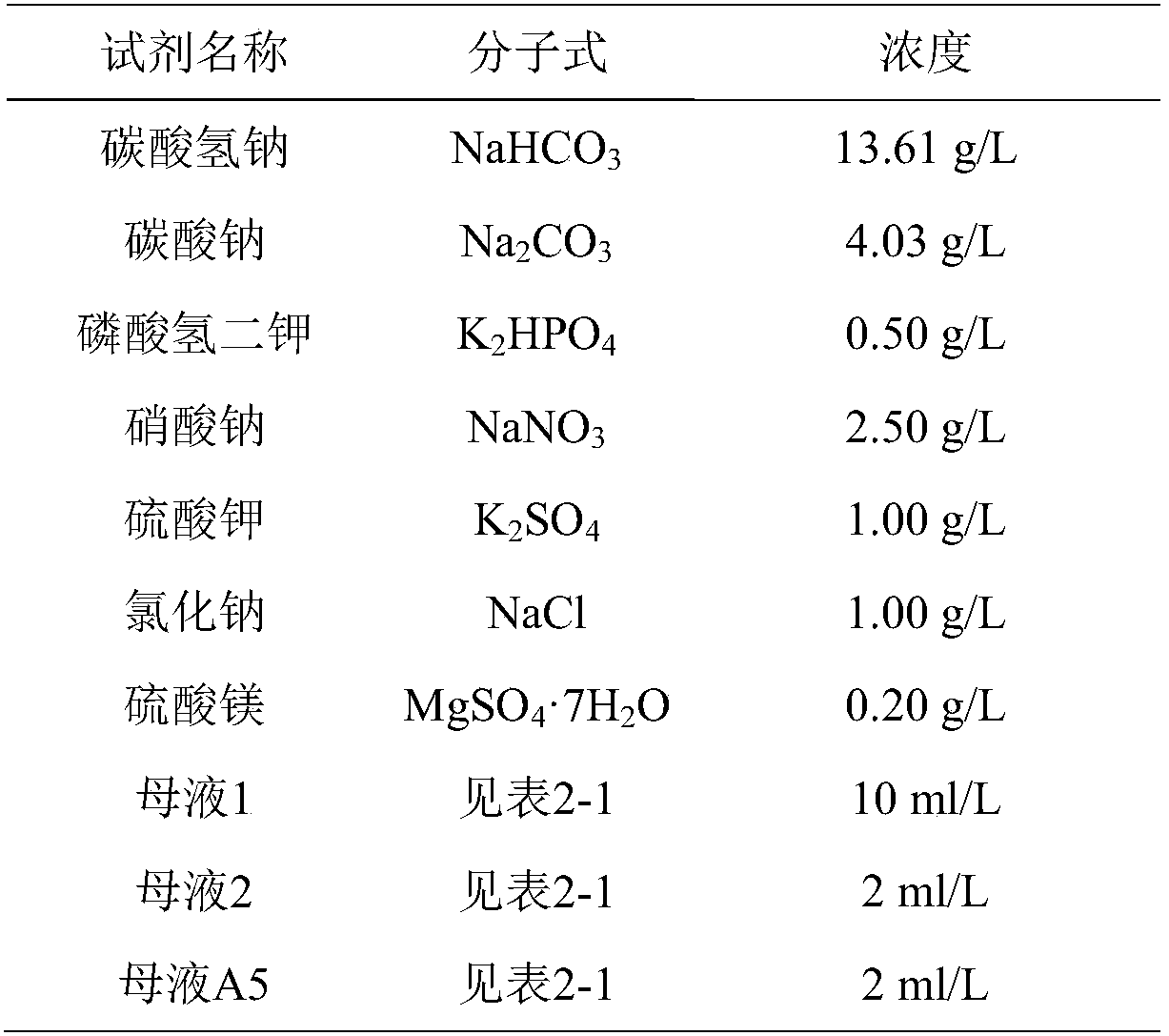

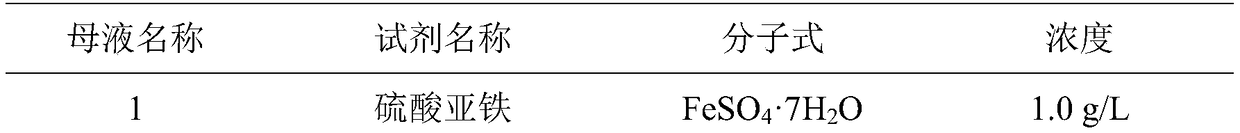

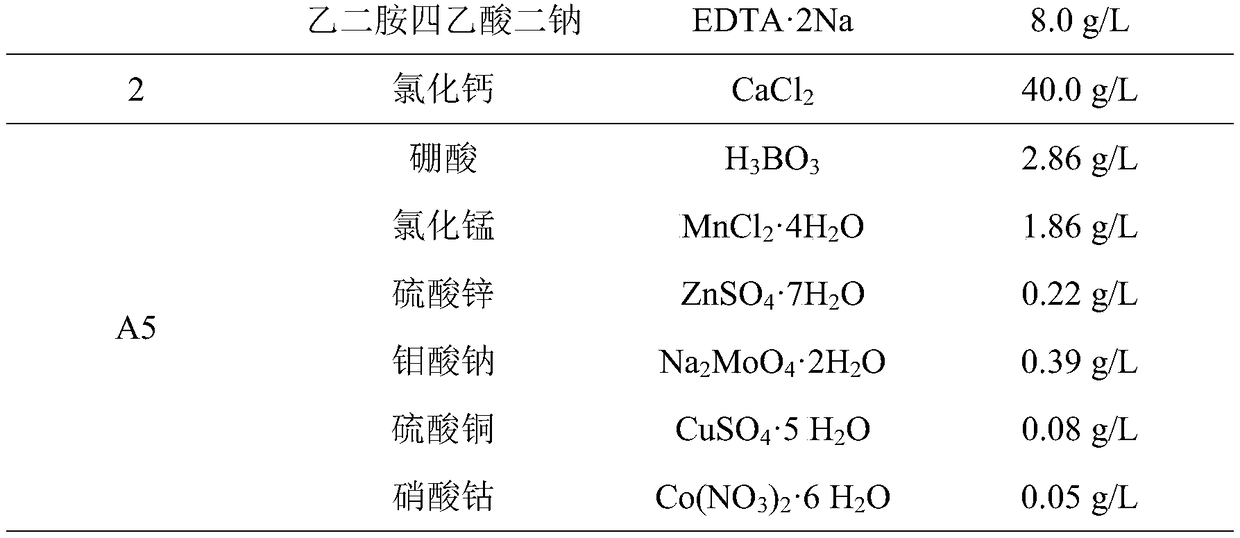

[0148] This algae cell is inoculated in the low-salt freshwater medium Zarrouk culture medium (see table 1 and table 2 for details), and initial inoculation concentration is 0.2g / L, and the temperature program of the freshwater medium of controlling cultivation this algae cell is: constant temperature 25°C, the light program is: continuous light, the light intensity is 500μE·m -2 ·s -2 , the light wavelength range is 400-700nm, the ventilation volume is: 0.3VVM, the gas passed through is mixed air containing carbon dioxide, and the carbon dioxide concentration is 5% (v / v).

[0149] The culture time at this stage is 5-7 days.

[0150] Wherein, the specific formula of the fresh water medium is Zarrouk medium (see Table 1 and Table 2 for details). (2) GG generation stage:

[0151] The algae cells are selected from the cells g...

Embodiment 2

[0163] Process 1, using the cultured GG-rich spirulina to obtain low-osmotic extraction stock solution products containing different concentrations of GG. An example of the method is as follows:

[0164] 1) Take 100 L of the algae mud obtained through the cultivation method for obtaining high-content GG algae cells (in Example 1), and dehydrate it.

[0165] 2) Add 100L of salt-free pure water (hypotonic solution) for the first extraction, and separate the algal water to obtain algal mud and 100L of GG aqueous solution with a GG concentration of 28g / L.

[0166] 3) Add 100 L of salt-free pure water to the algae mud obtained in 2) for the second extraction, and obtain the algae mud and 100 L of GG aqueous solution after separation of algae water, and the concentration of GG is 18 g / L.

[0167] 4) Add 100 L of salt-free pure water to the algae mud obtained in 3) for the third extraction, and obtain the algae mud and 100 L of GG aqueous solution after separation of algal water, an...

Embodiment 3

[0171] The GG product containing low pigment concentration is obtained by depigmenting the GG low-osmotic extraction raw liquid product obtained in the first step through the second and / or third step. An example of the method is as follows:

[0172] 1) Use procedure 1 to perform hypotonic extraction, and take 10 L of hypotonic extract containing 28 g / L GG obtained from the first extraction in Example 2 for subsequent treatment.

[0173] 2) The extract obtained in 1) is decolorized through a decolorization device with a membrane pore size of 450 Da in the second step, and the pigment removal rate reaches 35.3%.

[0174] 3) The solution in 2) is further decolorized through the NM100 resin in the third step, and the total removal rate of the pigment reaches 90.2%.

[0175] Through the above two-step process, the GG product with a pigment removal rate of 90.2% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com