A method for preparing porous graphitic carbon nitride using carbon nanotubes as a hard template

A technology of graphite phase carbon nitride and carbon nanotubes, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of complicated process, waste of resources, non-recyclable use, etc. Good repeatability, resource saving, and less impurity components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

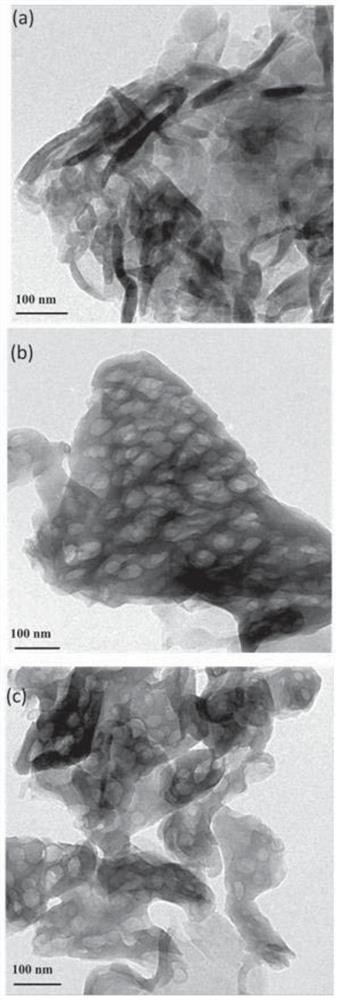

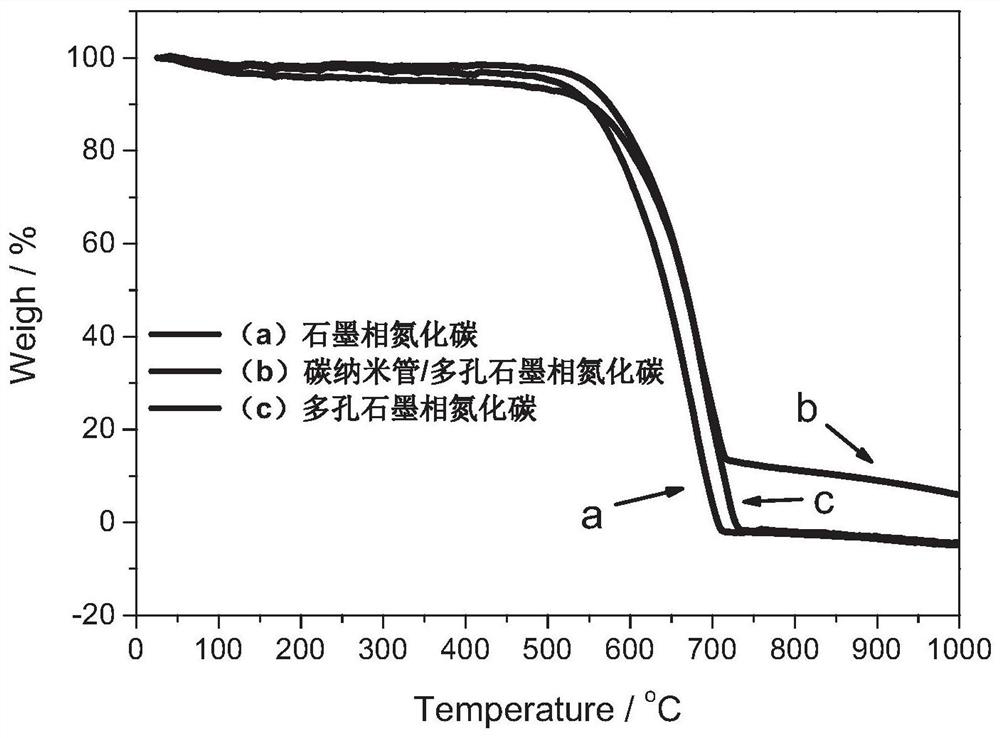

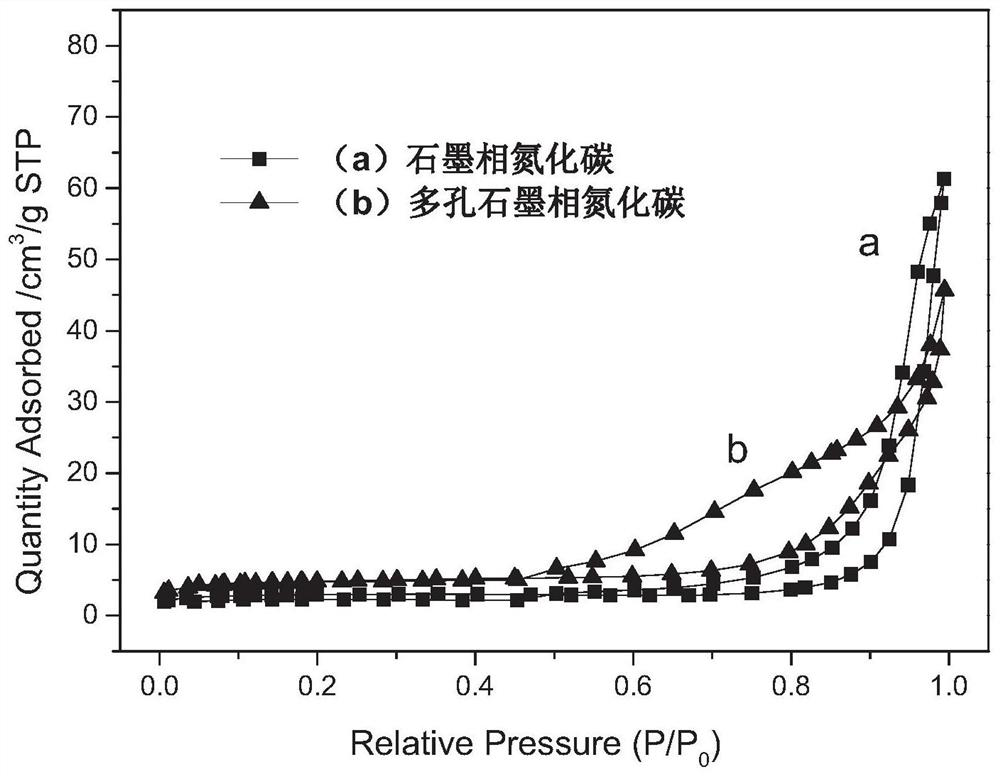

[0024] 4g of urea was used as the graphite phase carbon nitride precursor, and 50mg of multi-walled carbon nanotubes were used as the hard template. The two were ground and mixed evenly and placed in a covered crucible. After heating up in a nitrogen-protected tube furnace, the temperature was kept at 2.5 Heat up to 550°C at a heating rate of °C / min, hold for 4 hours, and then cool to room temperature. After ultrasonically dispersing the obtained solid in water for 10 min, take the upper dispersion liquid for another 10 min, and take the upper dispersion liquid to remove the carbon nanotubes. Centrifuge the upper layer dispersion liquid obtained by ultrasonication twice at 8000 rpm / min for 10 min, remove the lower layer and dry it in vacuum at 60° C. to obtain porous graphite phase carbon nitride.

Embodiment 2

[0026] Using 4g of dicyandiamide as the graphite phase carbon nitride precursor and 50mg of multi-walled carbon nanotubes as the hard template, the two are ground and mixed evenly and placed in a covered crucible, heated up in a nitrogen-protected tube furnace and then kept warm , heated to 550°C at a heating rate of 2.5°C / min, kept for 3 hours, and then cooled to room temperature. After ultrasonically dispersing the obtained solid in water for 10 min, take the upper dispersion liquid for another 10 min, and take the upper dispersion liquid to remove the carbon nanotubes. Centrifuge the upper layer dispersion liquid obtained by ultrasonication twice at 8000 rpm / min for 10 min, remove the lower layer and dry it in vacuum at 60° C. to obtain porous graphite phase carbon nitride.

Embodiment 3

[0028] Using 4g melamine as the graphite phase carbon nitride precursor and 100mg multi-walled carbon nanotubes as the hard template, the two were ground and mixed evenly and placed in a covered crucible, heated up in a nitrogen-protected tube furnace and then kept warm at 2.5 Heat up to 580°C at a heating rate of °C / min, hold for 3 hours, and then cool to room temperature. After ultrasonically dispersing the obtained solid in water for 10 min, take the upper dispersion liquid for another 10 min, and take the upper dispersion liquid to remove the carbon nanotubes. Centrifuge the upper layer dispersion liquid obtained by ultrasonication twice at 8000 rpm / min for 10 min, remove the lower layer and dry it in vacuum at 60° C. to obtain porous graphite phase carbon nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com