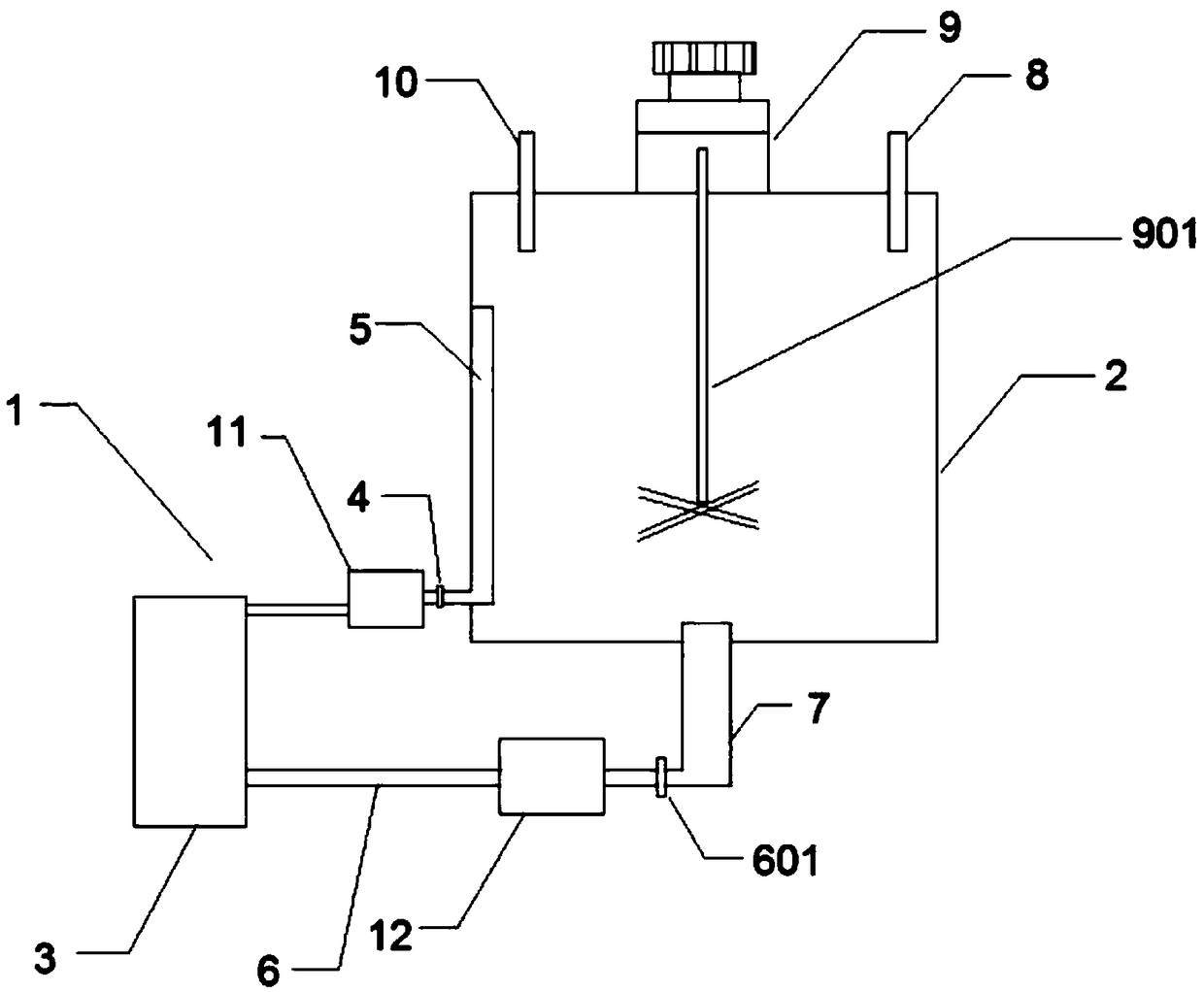

Preparation method and production device preventing citric acid coagulation

A production device and technology of citric acid, applied in the field of preparation method and production device to prevent citric acid from coagulating, can solve problems such as easy coagulation, achieve the effects of guaranteeing purity, improving anti-coagulation effect, and ensuring pressure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

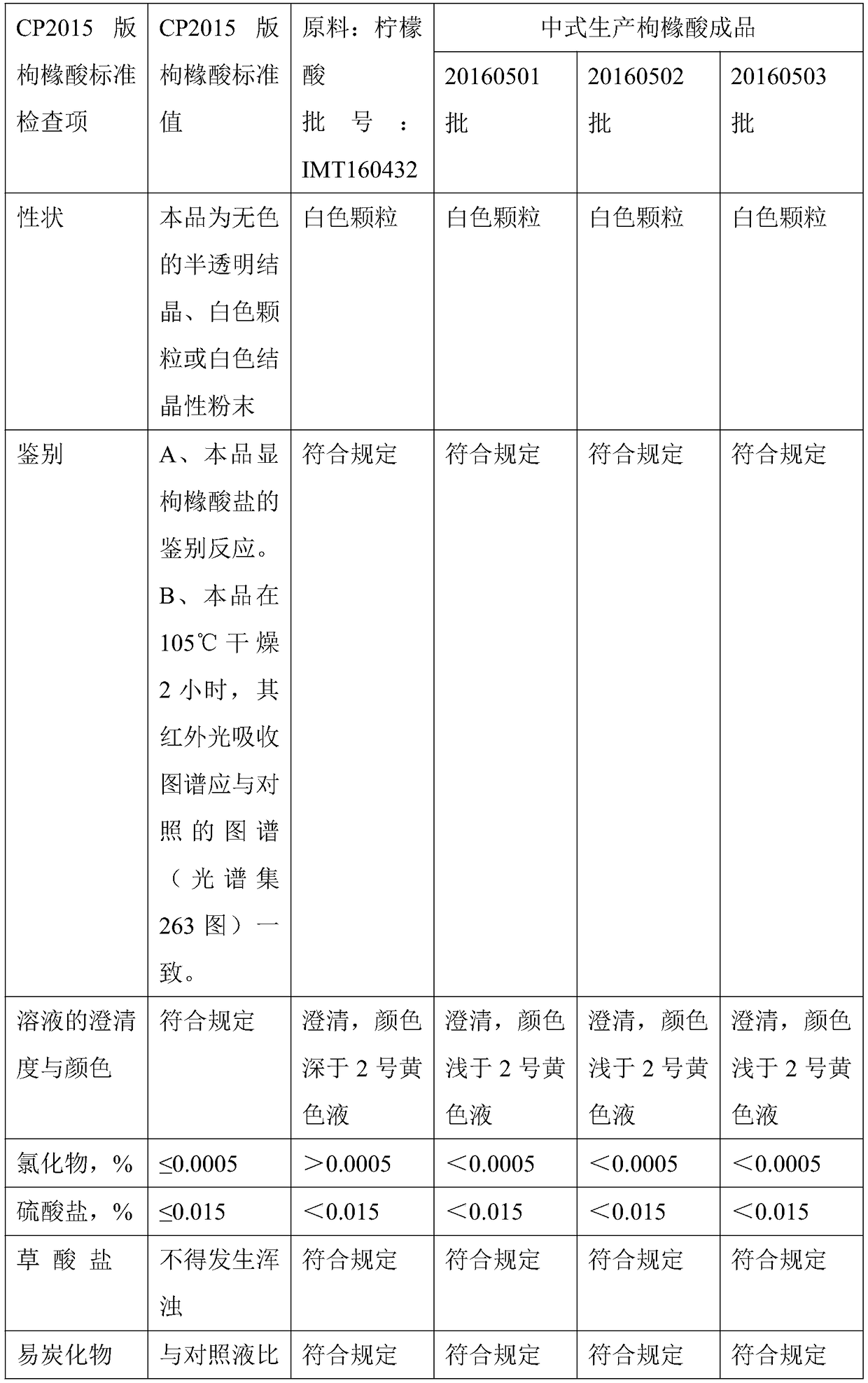

[0039] Embodiment 1 prevents the preparation method of citric acid coagulation

[0040] S1. Dissolution: Put 10kg of food-grade anhydrous citric acid crude product into the concentration tank, add 3L of purified water, vacuumize, and continuously feed 0.1MPa steam, heat the feed liquid to 80°C, and stir for 30min;

[0041] S2. Decolorization: add 0.1% activated carbon to the solution obtained in S1, vacuumize, slowly introduce 0.1MPa steam, stir at a constant temperature of 60° C. for 1 hour, and filter to obtain a fine filtrate;

[0042] S3. Concentration and crystallization: depressurize the fine filtrate obtained in S2 to -0.07MPa at 50°C, stir at a speed of 33r / min, concentrate for 4h until the specific gravity of the material reaches 1.34g / ml, cool to 20°C, and crystallize 8h to get citric acid wet granules;

[0043] S4. Separation and purification: the wet citric acid granules obtained in S3 were dehydrated, and dried in a vibrating fluidized bed at a temperature of 55°...

Embodiment 2

[0045] Embodiment 2 prevents the preparation method of citric acid coagulation

[0046] S1. Dissolution: Put 10kg of food-grade anhydrous citric acid crude product into the concentration tank, add 4L of purified water, vacuumize, and continuously feed 0.2MPa steam, heat the feed liquid to 90°C, and stir for 45min;

[0047] S2. Decolorization: add 0.4% activated carbon to the solution obtained in S1, vacuumize, slowly introduce 0.2MPa steam, stir at a constant temperature of 90° C. for 1 hour, and filter to obtain a fine filtrate;

[0048] S3. Concentration and crystallization: depressurize the fine filtrate obtained in S2 to -0.08MPa at 60°C, stir at a speed of 33r / min, concentrate for 8h until the specific gravity of the material reaches 1.40g / ml, cool to 28°C, and crystallize 8h to get citric acid wet granules;

[0049] S4. Separation and purification: the wet citric acid granules obtained in S3 were dehydrated, and dried in a vibrating fluidized bed at a temperature of 55°...

Embodiment 3

[0051] Embodiment 3 prevents the preparation method of citric acid coagulation

[0052] S1. Dissolution: Put 10kg of food-grade anhydrous citric acid crude product into the concentration tank, add 5L of purified water, vacuumize, and continuously feed 0.3MPa steam, heat the feed liquid to 100°C, and stir for 60min;

[0053] S2. Decolorization: add activated carbon with a mass percentage of 0.6% to the solution obtained in S1, vacuumize, slowly introduce 0.3MPa steam, stir at a constant temperature of 100° C. for 1 hour, and filter to obtain a fine filtrate;

[0054] S3. Concentration and crystallization: depressurize the fine filtrate obtained in S2 to -0.09MPa at 70°C, stir at a speed of 33r / min, concentrate for 10h until the specific gravity of the material reaches 1.86g / ml, cool to 40°C, and crystallize 8h to get citric acid wet granules;

[0055] S4. Separation and purification: the wet citric acid granules obtained in S3 were dehydrated, and dried in a vibrating fluidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com