Extracting-purifying method for coenzyme Q10 and prepared coenzyme Q10

A purification method and coenzyme technology, applied in quinone separation/purification, organic chemistry and other directions, can solve problems such as difficulty, improper process design, emulsification phenomenon, etc., and achieve the effects of simple steps, small loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

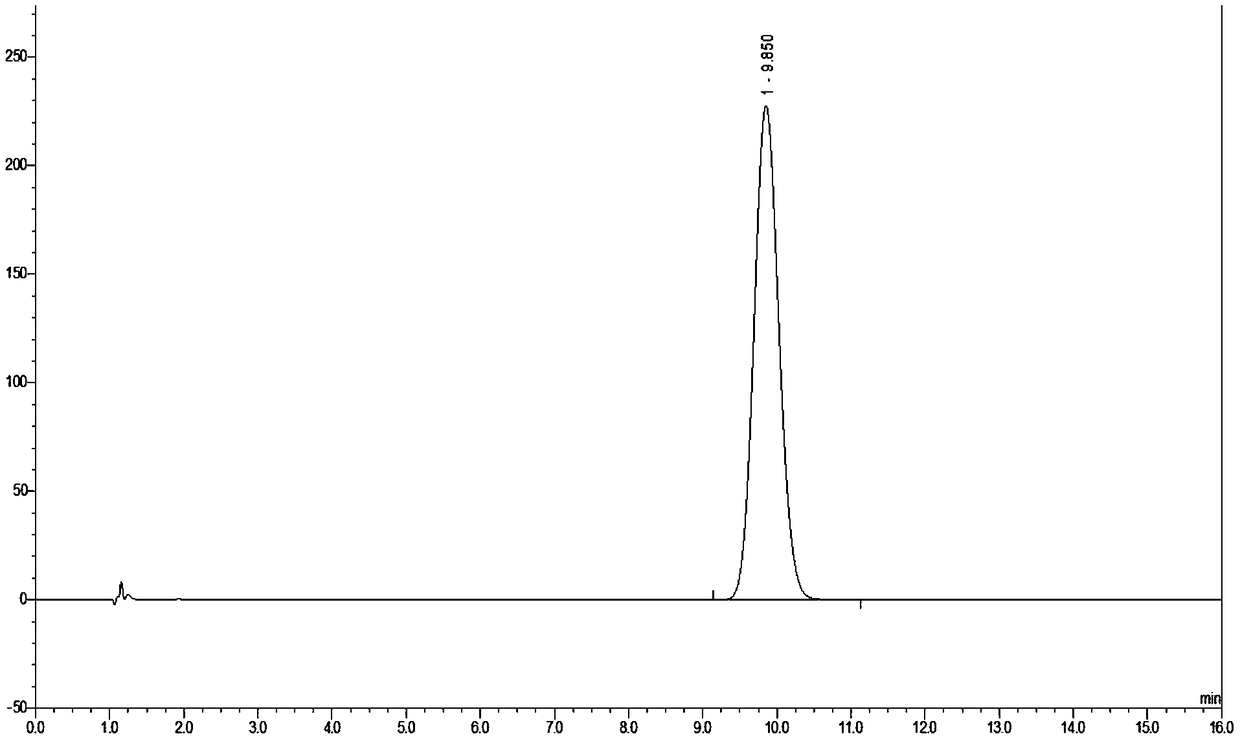

Image

Examples

Embodiment 1

[0053] i) extract

[0054] Take 780g of coenzyme Q10 bacteria (the content of coenzyme Q10 is 5.0%, the water content is 2.1%), after simple grinding, add n-hexane:methanol:water with a volume ratio of 9:3:1 (v / v / v) Mixed solvent 8L. The temperature is controlled at 25°C, and after mechanical stirring, it is left to stand for stratification. The upper layer is the n-hexane phase containing the product, and the lower layer is the methanol / water solution containing the bacteria residue. After the oil-water two phases were separated, the supernatant was evaporated in a rotary evaporator at 40°C to obtain 100.14 g of coenzyme Q10 extract. The measured content of coenzyme Q10 was 38.9%, and the yield was 99.8%. The methanol / water solution containing bacteria residue in the lower layer undergoes solid-liquid separation after sedimentation and filtration, and the solvent can be recycled for reuse. ii) Precipitation

[0055] Melt the coenzyme Q10 extract obtained in the extraction ...

Embodiment 2

[0061] The steps i) and step ii) of coenzyme Q10 extraction and purification were carried out in the same manner as in Example 1, wherein the coenzyme Q10 extract obtained after step i) was 98.54 g, the content of coenzyme Q10 was 39.5%, and the yield was 99.8%, the impurity-removed processed product obtained after step ii) precipitation is 56.48g, the content of coenzyme Q10 is 68.7%, and the yield is 99.7%. The treated product after removal of impurities is subjected to the adsorption decolorization operation of the following step iii).

[0062] First, dissolve 56.48g of the impurity-removed treatment in 800mL of n-hexane, then spread 2 layers of filter paper at the bottom of the φ7cm Buchner funnel, then take 30.86g of powdered activated clay, add n-hexane and spread it on the filter paper, and finally Spread 1 layer of filter paper on the stuffing. Suction filter the coenzyme Q10 solution dissolved in n-hexane with a Buchner funnel until the dripping liquid has no color a...

Embodiment 3

[0065]Coenzyme Q10 was extracted in the same manner as step i) of Example 1, except that cyclohexane:ethyl acetate:water was used in a mixed solvent with a volume ratio of 8:5:1 (v / v / v). The coenzyme Q10 extract obtained after separating the oil-water two phases and rotary evaporation was 100.01 g, the measured coenzyme Q10 content was 38.8%, and the yield was 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com