Preparation method of fiber enhanced thermal-shock-resisting foam ceramic

A foamed ceramic and fiber-reinforced technology, which is applied in the field of foamed ceramic material preparation, can solve the problems of high thermal conductivity of ceramic materials, easy cracking of ceramics, low mechanical strength, etc. The effect of reducing the property and thermal conductivity

Inactive Publication Date: 2018-11-23

FOSHAN LINGCHAO NEW MATERIAL CO LTD

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] The technical problem mainly solved by the present invention is to provide a fiber-reinforced anti-foaming ceramics for the defects that the mechanical strength is low due to the existence of the pore st

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

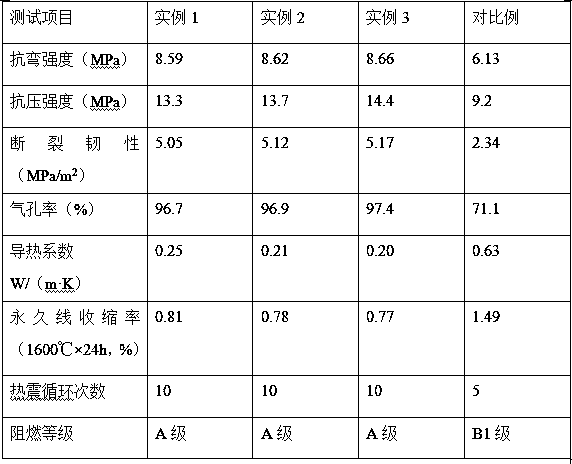

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of preparation of foam ceramic materials and in particular relates to a preparation method of fiber enhanced thermal-shock-resisting foam ceramic. The preparation method comprises the following steps: mixing silicon carbide powder, corundum powder and kaolin powder, and putting a mixture into silica sol to obtain silicon carbide foam ceramic slurry; putting polyurethane sponge into paraffin wax silica sol formed by mixing silicon dioxide coated paraffin wax microcapsules and the silica sol to obtain a foam ceramic preformed body; finally, filling the foam ceramic preformed body into a mold and filling the silicon carbide foam ceramic slurry; firing to obtain the fiber enhanced thermal-shock-resisting foam ceramic. Paraffin wax in the silicon oxide coated paraffin wax microcapsules is hotly melted to obtain a liquid-state lubricant, and communication and overlapping of pore structures can be prevented, so that the effect of improving the closed pore rate is realized; paraffin wax, which is not decomposed, of an inner layer can absorb heat at high temperature and flows to dissipate heat, so that the thermal conductivity of the foam ceramicis reduced; silicon carbide is used as a framework in a matrix, so that the mechanical properties of the foam ceramic can be improved; the foam ceramic has a wide application prospect.

Description

technical field [0001] The invention belongs to the technical field of foam ceramic material preparation, and in particular relates to a preparation method of fiber-reinforced thermal shock-resistant foam ceramics. Background technique [0002] Foam ceramics are the third generation of porous ceramics developed after porous ceramics and honeycomb ceramics. They are porous ceramic bodies with high porosity and three-dimensional space grid structure. Ceramic foam has excellent ceramic intrinsic properties such as high melting point, corrosion resistance and wear resistance, and due to the introduction of a large number of pores, it also has low thermal conductivity, controllable permeability, high specific surface area, low density, high specific strength, low properties such as dielectric constant. As a high-performance green environmental protection material, ceramic foam has been widely used in purification and separation, chemical catalyst carrier, advanced insulation mat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/80C04B35/565C04B35/622C04B38/06

CPCC04B35/565C04B35/622C04B35/806C04B38/0615C04B2235/3217C04B2235/3418C04B2235/349C04B2235/5236C04B2235/96C04B2235/9607C04B38/0074

Inventor 裘友玖章红英赵金晶

Owner FOSHAN LINGCHAO NEW MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com