Preparation method of phenol modified urea resin

A technology of urea-formaldehyde resin and phenol is applied in the field of preparation of phenol-modified urea-formaldehyde resin, which can solve the problems of serious opening, increased acidity, aging of adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of phenol modified urea formaldehyde resin, comprises the following steps:

[0023] a) reacting after mixing phenol, formaldehyde and a basic catalyst to obtain a reaction product, which includes a mixture of phenol alcohols and formaldehyde;

[0024] b) mixing the reaction product obtained in step a) with urea, alcohol compounds and weak acid compounds, and reacting to obtain a phenol-modified urea-formaldehyde resin.

[0025] In the method provided by the invention, firstly, phenol and formaldehyde are reacted in the presence of a basic catalyst, and then the obtained phenol-alcohol mixture is reacted with urea and an alcohol compound in the presence of a weak acid compound to obtain a phenol-modified urea-formaldehyde resin. In the above reaction process, the hydroxyl group in the alcohol compound can react with free formaldehyde to form alcohol formal, and the alcohol compound can also cross-link with the urea-for...

Embodiment 1

[0045] Mix 476g of phenol, 2081g of formaldehyde solution with a mass concentration of 37% and 10.8g of polyvinyl alcohol, then add sodium hydroxide to it to adjust the pH value of the mixed solution to 8.0, and place the resulting mixed solution with a pH value of 8.0 at 70°C Under constant temperature reaction 2h;

[0046] Then add 1080g of urea to the obtained reaction solution in 3 batches: first add 648g of the first batch of urea and then raise the temperature to 98°C, and add 16.2g of furfuryl alcohol to the reaction solution before adding 324g of the second batch of urea, and then add formic acid to adjust the reaction The pH value of the solution is 5.5, and finally the third batch of urea 108g is added to the reaction solution with a pH value of 5.5, and the phenol-modified urea-formaldehyde resin is obtained after reacting for 1 hour.

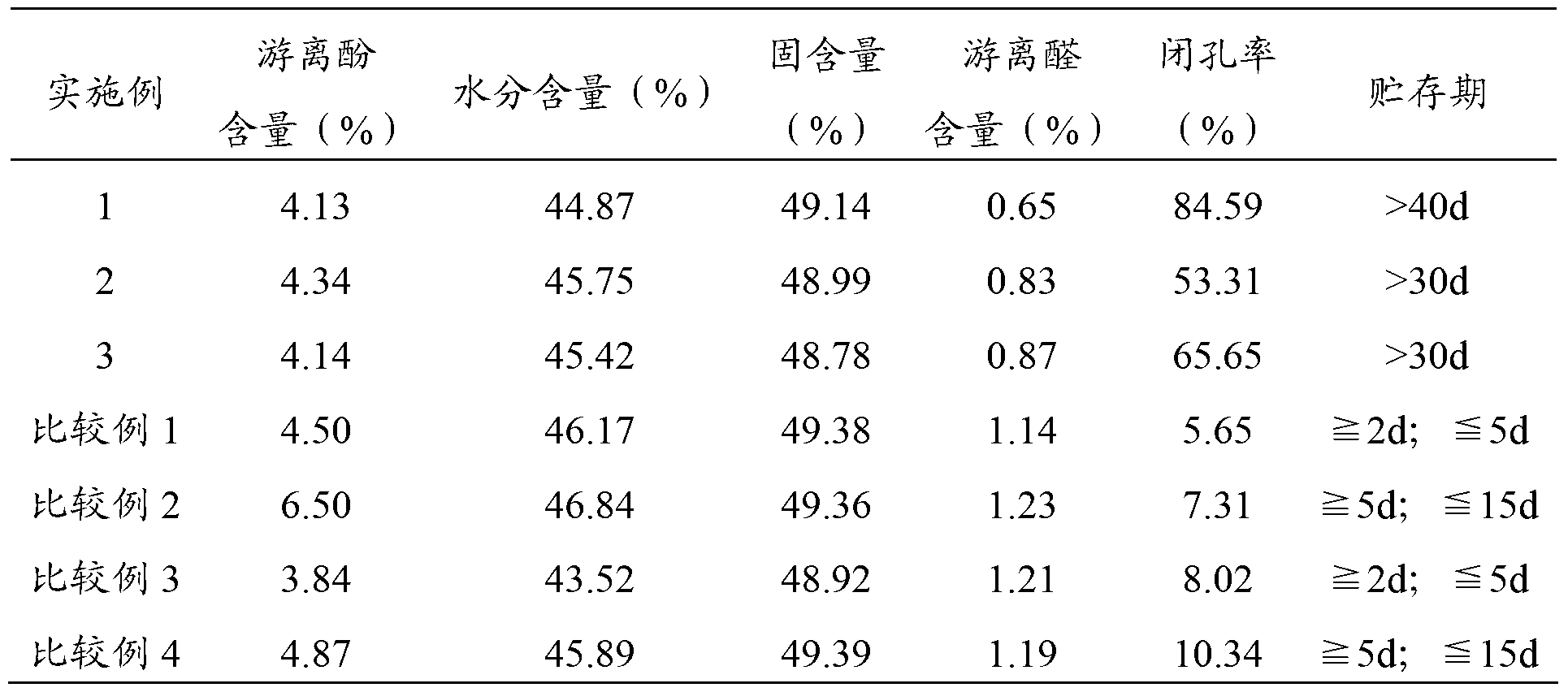

[0047] The free phenol content, moisture content, solid content, free aldehyde content, closed cell rate and storage period of the ...

Embodiment 2

[0049] 476g phenol, 2081g mass concentration are 37% formaldehyde solution and 10.8g polyvinyl alcohol mix, then add sodium hydroxide to it and adjust the pH value of the mixed solution obtained to be 8.0, the mixed solution with the obtained pH value of 8.0 in Constant temperature reaction at 70°C for 2 hours;

[0050] Then 1080g of urea was added to the obtained reaction solution in 4 batches: after the constant temperature was completed, the first batch of urea 702g was directly added to the obtained reaction solution, and then the second batch of urea 216g was added thereto. After the reaction solution was heated to 98°C, and Before adding the 3rd batch of urea 108g, add 16.2g furfuryl alcohol to the reaction solution, add formic acid to it after adding the 3rd batch of urea to adjust the pH value of the reaction solution to 5.5, and finally add the 4th batch to the reaction solution with a pH value of 5.5. Batch 54g of urea and react for 2 hours to obtain phenol-modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com