Production method of activated carbon special for wine

A production method and activated carbon technology, which are applied in the preparation of alcoholic beverages, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long processing time, loss of aroma main body, and large amount of use, so as to achieve a pure and soft taste, and accelerate molecular Associative effect, the effect of reducing the spicyness of the wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

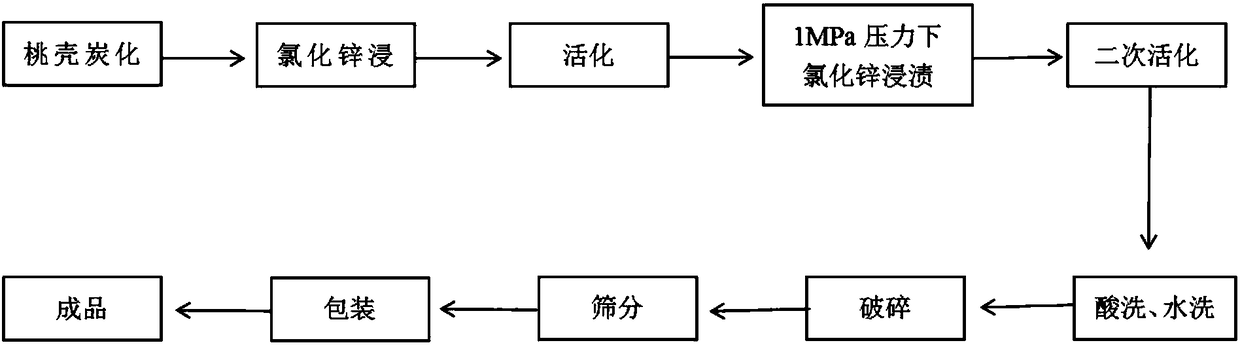

Method used

Image

Examples

Embodiment 1

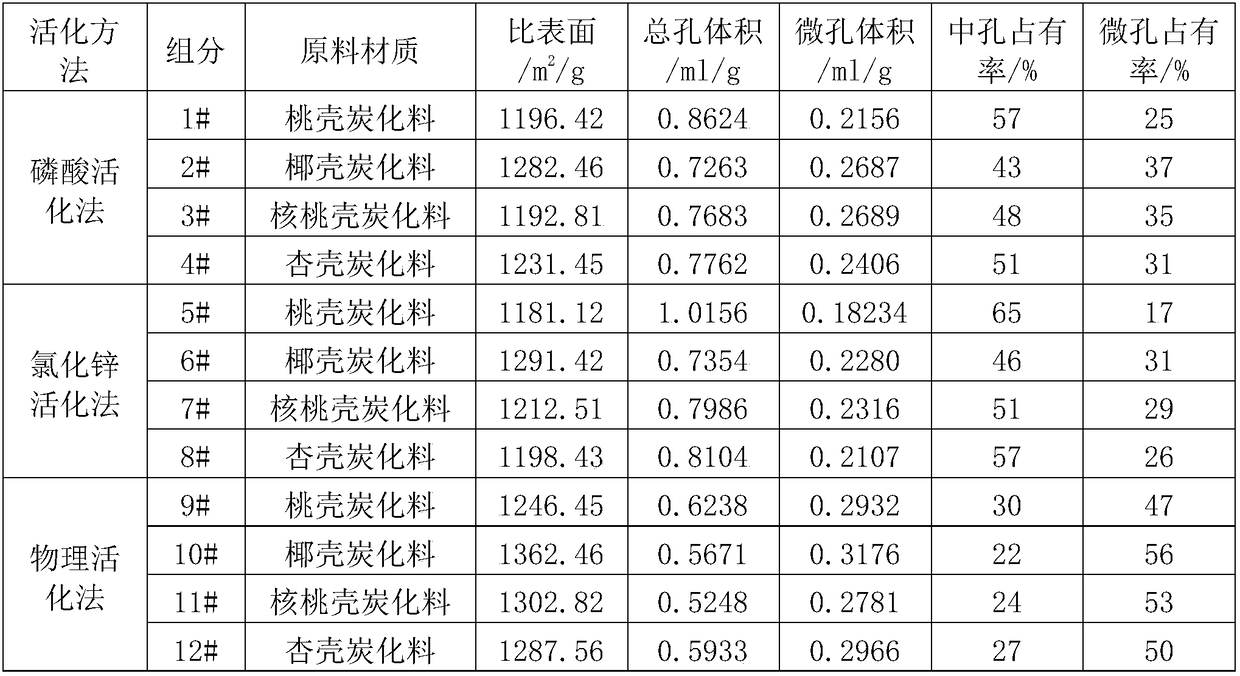

[0025] Phosphoric acid activation method: Peach shell carbonized material, coconut shell carbonized material, walnut shell carbonized material and apricot shell carbonized material are soaked in phosphoric acid solution respectively, activated at 550°C for 2 hours, then pickled and washed with water to obtain activated carbon.

Embodiment 2

[0027] Zinc chloride activation method: Peach shell carbonized material, coconut shell carbonized material, walnut shell carbonized material and apricot shell carbonized material are respectively impregnated in zinc chloride solution, the impregnation ratio is 4, activated at 700 ° C for 2 hours, and then Pickling, water washing to get activated carbon.

Embodiment 3

[0029] Physical activation method: the peach shell carbonized material, coconut shell carbonized material, walnut shell carbonized material and apricot shell carbonized material are physically activated, CO 2 and water vapor as an activator, activated for 2 hours, then pickled and washed with water to obtain activated carbon.

[0030] Carry out pore size analysis to the product in embodiment 1 to embodiment 3, the results are shown in table 1

[0031] Table 1

[0032]

[0033] It can be seen from Table 1 that the activated carbon produced by the zinc chloride activation method has a relatively high mesopore occupancy rate. Although the activated carbon produced by the physical activation method has a large specific surface area, the micropore occupancy rate is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com