Laser welding fixing device for spectacle frame

A fixing device and laser welding technology, which is applied in the direction of laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of small size of nose pads and other components, low degree of automation, and difficulty in ensuring welding accuracy, so as to avoid inaccurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

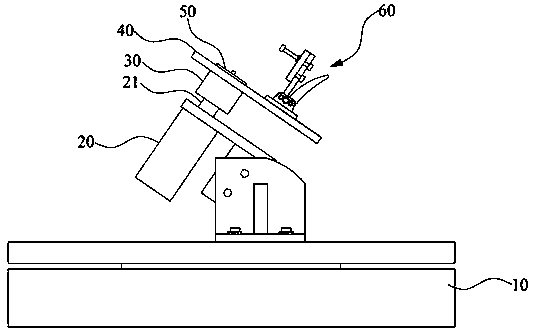

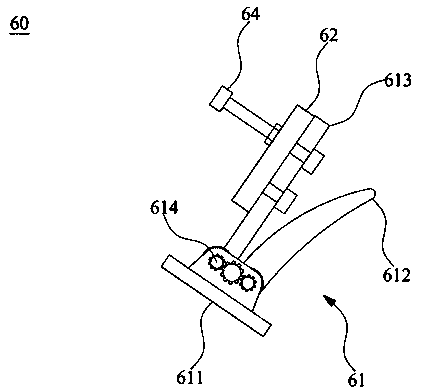

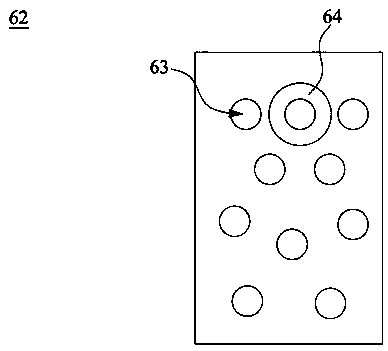

[0020] Please also refer to figure 1 , figure 1 It is a schematic diagram of a laser welding and fixing device for a mirror frame according to an embodiment of the present invention. As shown in the figure, a mirror frame laser welding and fixing device includes a base 10; a rotating motor 20 installed on the base 10, and the rotating motor 20 has a rotating main shaft 21; a positioning seat cover 30 fixed on the rotating main shaft 21; buckled on the positioning seat The clamp mounting plate 40 of the cover 30; the frame positioning mold 50 fixed to the clamp mounting plate 40 by bolts, and the bolts are set to the positioning seat cover 30; and the movable press butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com