Welding machine based on visual localization and automatic welding method

A visual positioning and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as welding defects, reduce hazards, improve welding quality and efficiency, and release hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

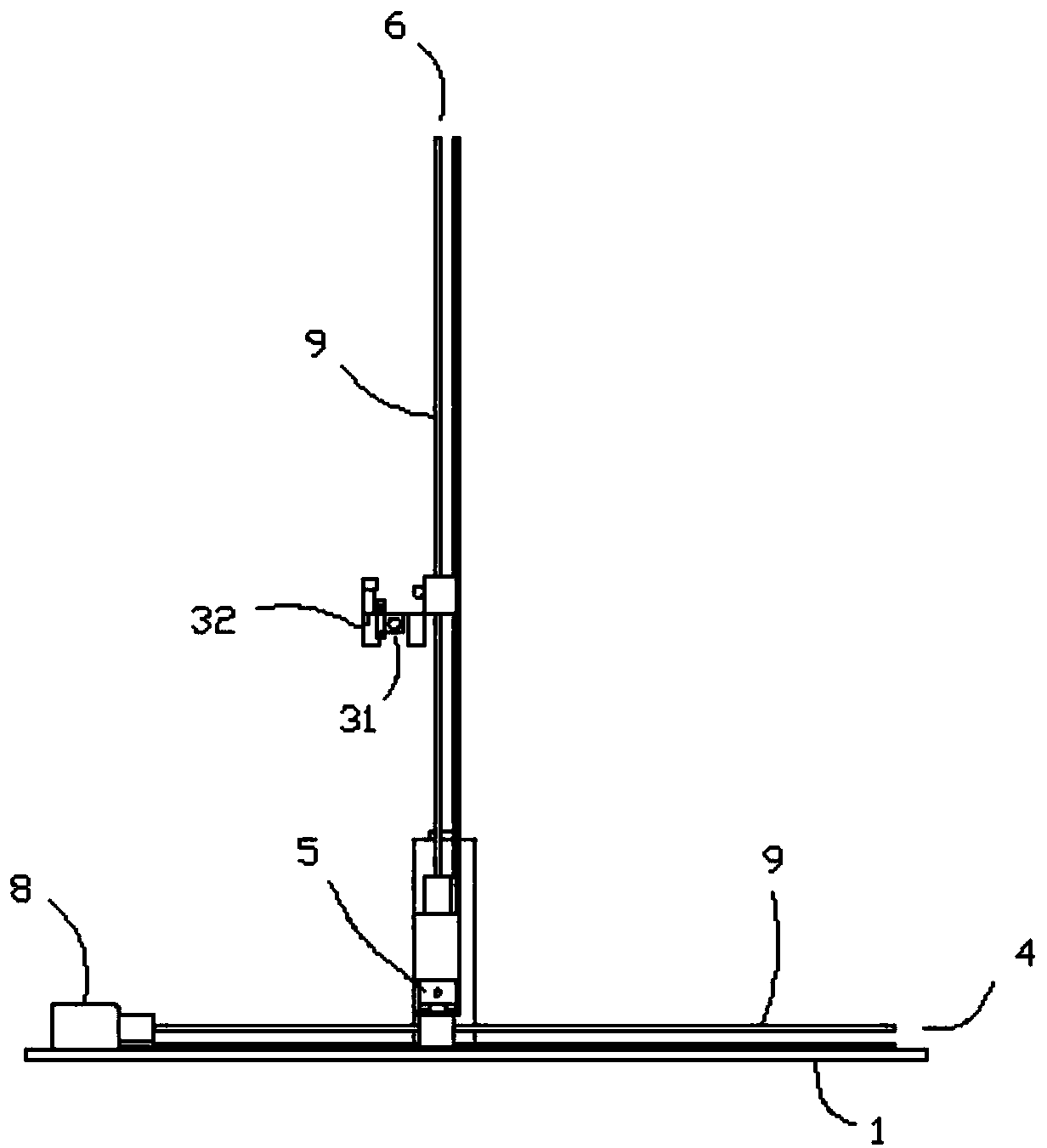

[0039] like figure 1 and figure 2 As shown, a welding machine based on vision positioning includes a base 1 , a motion mechanism, a welding torch module 2 and a vision positioning module 3 . The base 1 is used to support other components, and the motion mechanism is installed on the base 1 and connected to the welding torch module 2 for driving the welding torch module 2 to move in the front-rear, left-right and up-down directions.

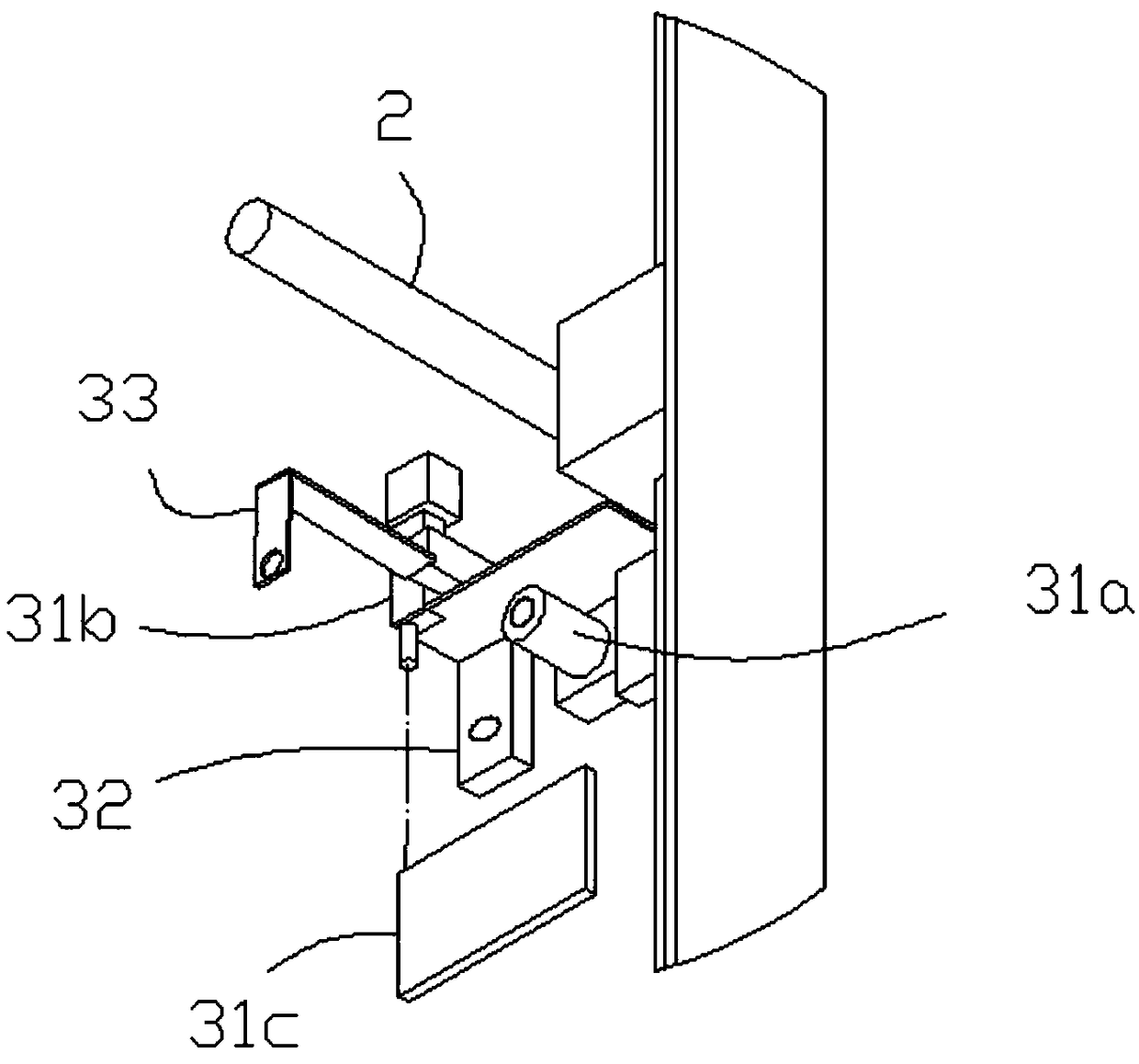

[0040] combine image 3 and Figure 4 As shown, the visual positioning module 3 includes an image acquisition module 31, an illumination module 32, a reference object and an image processing device; the image acquisition module 31 is fixedly connected with the welding torch module 2 for acquiring image information of the workpiece to be welded; The illumination module 32 cooperates with the image ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com