Lightweight backfill-type friction stir spot welding device

A friction stir and spot welding device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as elastic deformation, complex structure, and poor spot welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

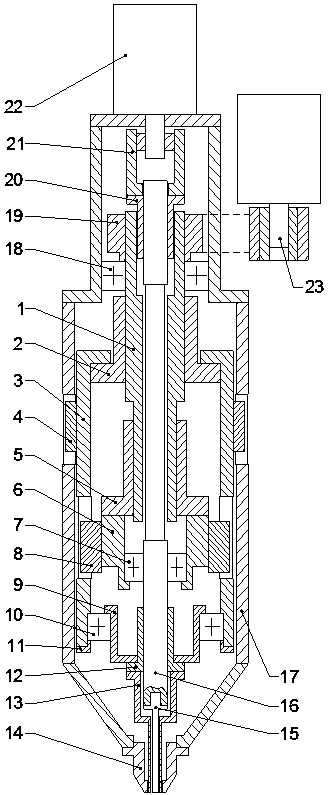

[0015] like figure 1 The shown lightweight backfill friction stir spot welding device includes an outer shell 17 and a stirring head made up of a stirring needle 15, a tubular sleeve 13 and a jacket 14, and the jacket 14 is fixed on the lower end of the outer shell for compaction. For the workpiece to be welded, the sleeve 13 can slide up and down in the sleeve 14, and the stirring needle 15 can rotate freely and slide up and down in the sleeve 13. The lower part of the sleeve is in the shape of a round tube, and the lower part of the stirring needle is inserted into the sleeve. The part in the lower part is a matching cylinder, the contact surface between the sleeve 13 and the stirring needle 15 and the contact surface between the sleeve 13 and the jacket 14 are all mirror surfaces, and the outer casing 17 is longitudinally provided with a transmission screw. It is a hollow two-way ball screw, which includes a hollow screw 1, a left-handed nut 2 and a right-handed nut 5. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com