Composite photocatalyst for photolyzing water and degrading pollutants and preparation method thereof

A technology of catalyst and composite light, which is applied in the field of photocatalyst and inorganic semiconductor photocatalysis, can solve the problems of complex catalyst synthesis process, long preparation cycle, low application prospect, etc., achieve good scalability, realize removal, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example involves a preparation method of a composite photocatalyst with ordered mesoporous morphology and its photolysis water activity test:

[0038] Step 1, weigh 0.5464g of citric acid monohydrate and 0.1241g of ethylene glycol and dissolve in 15ml of deionized water; the pH value of the complex solution is 2.0;

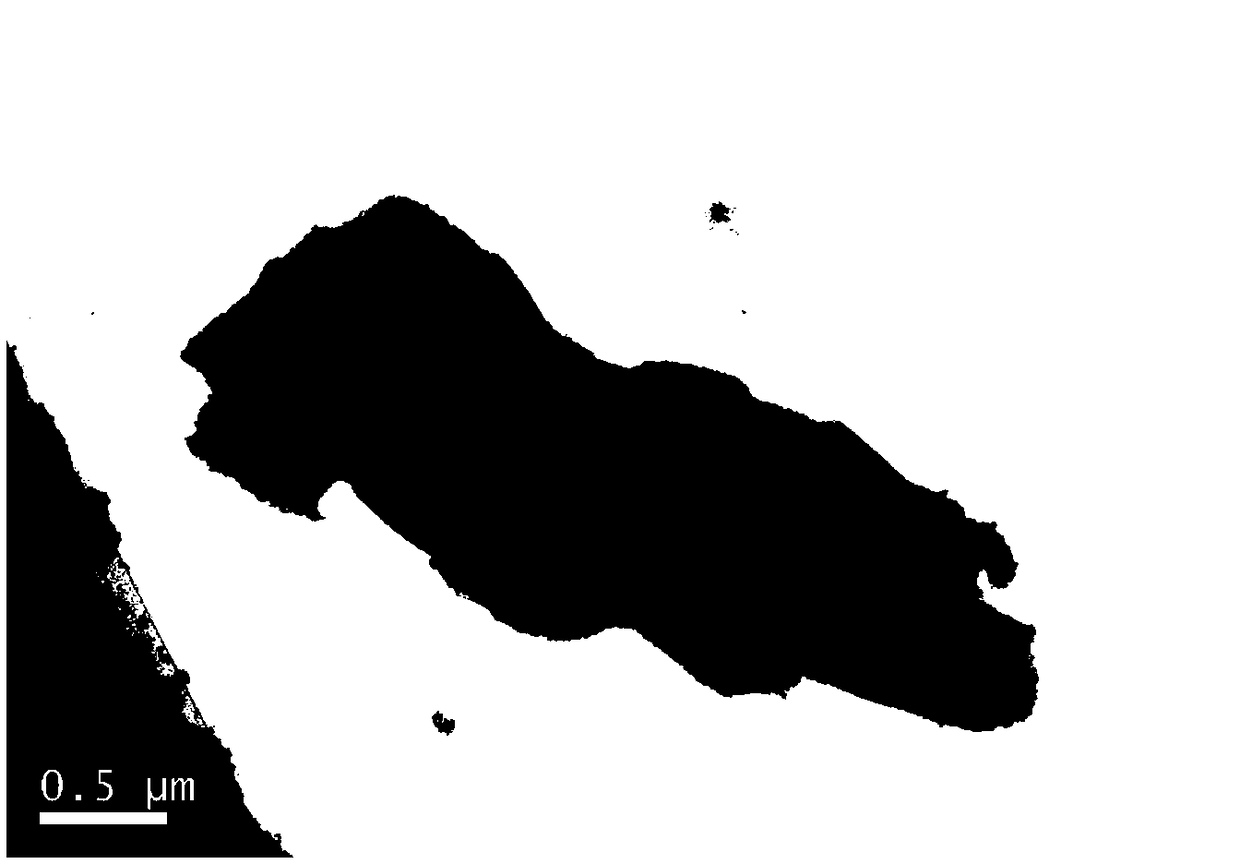

[0039] Step 2, take by weighing 0.4851g bismuth nitrate pentahydrate Bi(NO 3 ) 3 ·5H 2 O as bismuth source, 0.3830g yttrium nitrate hexahydrate Y (NO 3 ) 3 ·6H 2 O as yttrium source, 0.2340 g ammonium metavanadate NH 4 VO 3 As a vanadium source, add it to the solution obtained in step 1 in sequence, stir magnetically for 30 minutes and disperse ultrasonically for 30 minutes to form a uniform suspension; weigh 0.334 g of the prepared silica template (SBA-15) (TEM image see figure 1 ),from figure 1 It can be seen that the prepared SBA-15 has a good mesoporous channel structure with a pore diameter of about 6 nm and a wall thickness of about 5 nm....

Embodiment 1-1

[0061] This example is a modification example of Example 1, which only involves changing the calcination temperature and time: specifically, in Step 3 of Example 1: evaporate the suspension obtained in Step 2 to dryness in a water bath at 80°C, and place it in an oven at 80°C After drying for 12 hours, grind and collect, put it into a porcelain crucible with a volume of 50ml, raise the temperature in a muffle furnace at a rate of 1°C / min to 600°C and keep it calcined for 12 hours. After cooling, take it out and grind it to obtain a dry powder solid The same; other steps and test conditions remain unchanged. The average hydrogen and oxygen production rates obtained in the test were 128.3 μmol / h and 59.4 μmol / h, respectively.

Embodiment 1-2

[0063] This example is a modification example of Example 1, which only involves changing the calcination temperature and time: specifically, in Step 3 of Example 1: evaporate the suspension obtained in Step 2 to dryness in a water bath at 80°C, and place it in an oven at 80°C After drying for 12 hours, grind and collect, put it into a porcelain crucible with a volume of 50ml, raise the temperature in a muffle furnace at a rate of 1°C / min to 400°C and keep it calcined for 6 hours. After cooling, take it out and grind it to obtain a dry powder solid The same; other steps and test conditions remain unchanged. The average hydrogen and oxygen production rates obtained in the test were 5.4 μmol / h and 8.7 μmol / h, respectively.

[0064] Through experimental characterization, the results show that composite structures and solid solutions can be formed at 400°C, but the low activity is due to the low temperature and time, and the crystallinity is not high enough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com