Photocatalyst of shell-core structure as well as preparation method thereof and application thereof

A technology of photocatalyst and core-shell structure is applied in the field of core-shell structure photocatalyst and its preparation, which can solve the problems of increased use cost, high recombination rate, and difficulty in recycling and reusing photocatalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

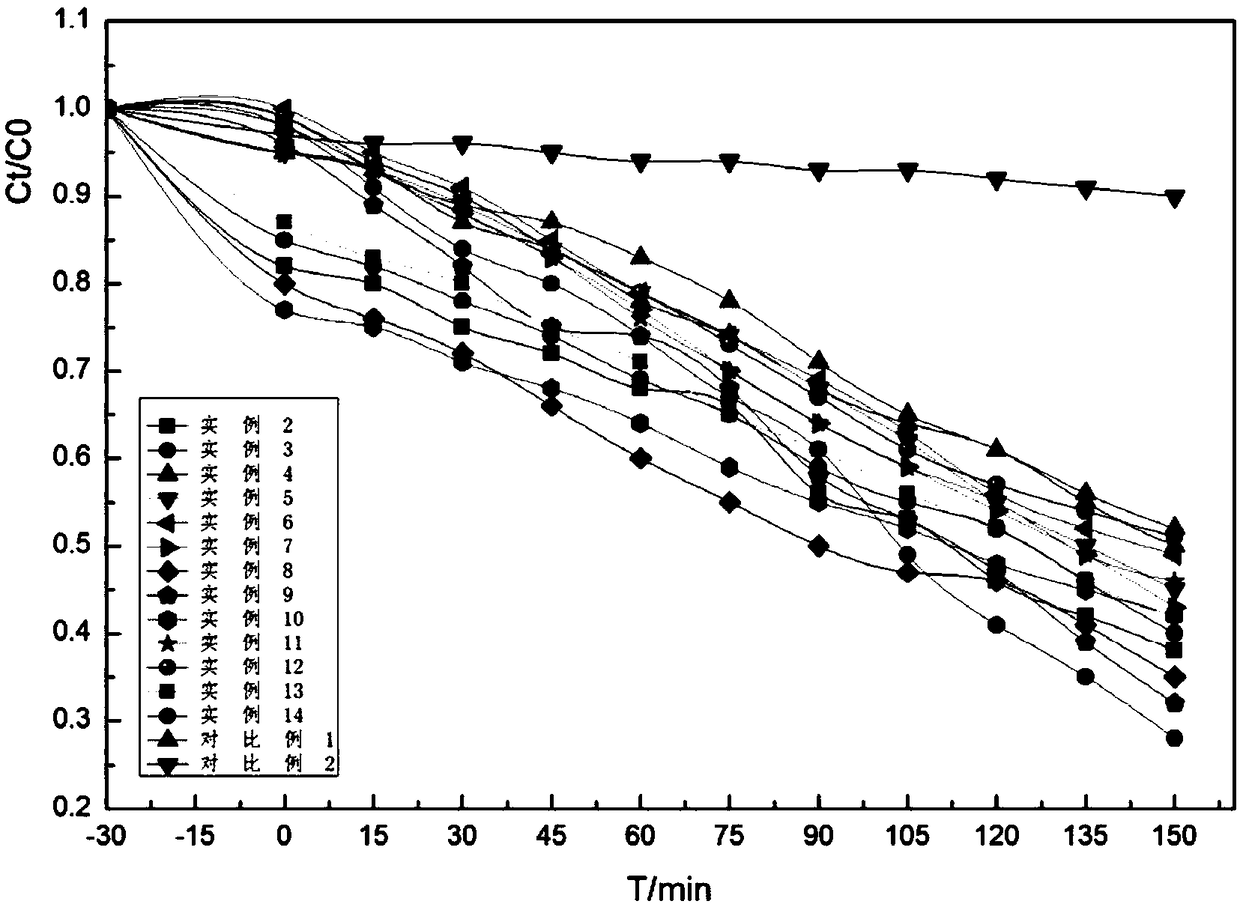

[0092] As a preferred embodiment of the present invention, the Fe 3 o 4 The weight ratio with NiAl-LDHs is 1:2.5-5; the Fe 3 o 4 @LDHs with Bi 2 MoO 6 The weight ratio is 1-1.5:2.5.

[0093] In a preferred embodiment of the present invention, Examples 2, 3, 8, and 10 of the present invention are adjusted by Fe 3 o 4 The weight ratio with NiAl-LDHs is 1:2.5-5, and the adjustment of Fe 3 o 4 @LDHs with Bi 2 MoO 6 The weight ratio is 1-1.5:2.5, further enhances its photocatalytic activity, in photocatalytic experiment, after 150min, the methylene blue remaining amount of embodiment 2,3,8,10 is all below 42%, especially embodiment In 3, only 28% of the methylene blue remains, and the obtained photocatalyst has high stability and degradation rate while being cost-effective.

[0094] According to another aspect of the present invention, the present invention provides the preparation method of described core-shell structure photocatalyst, comprises the following steps:

...

Embodiment 1

[0163] 1. Synthesis of core-shell structured photocatalysts

[0164] (1) Synthesis of Fe 3 o 4

[0165] Weigh 1.35g of FeCl 3 ·H 2 O, 3.6g NaAc, 1g polyethylene glycol, and 60mL ethylene glycol were put into a three-necked flask with a capacity of 250mL, and after ultrasonic mixing at room temperature for 15min, the mother liquor was transferred to a hydrothermal kettle, and placed in an oven at 200°C with water Heat for 10 hours.

[0166] After 10h, the hydrothermal kettle was taken out from the oven and cooled. After being cooled to room temperature, it was centrifuged with a centrifuge (10000r / min, 3min), washed repeatedly with distilled water for 3 times, and then washed once with ethanol to remove the supernatant. The sample was dried; after drying, it was ground into powder for later use.

[0167] (2) Synthesis of Fe 3 o 4 @LDHs

[0168] Weigh 0.1g of Fe 3 o 4 , use a pipette to pipette 20mL of prepared Ni 2+ 、Al 3+ Ionic solution (Ni 2+ Nickel nitrate aqueou...

Embodiment 2-14

[0182] Fe in step (2) 3 o 4 、Ni 2+ with Al 3+ Ionic solution, concentration are the addition of the NaOH aqueous solution of 1M as shown in table 1, in step (3), Fe 3 o 4 @LDHs, 0.4M Bi(NO 3 ) 3 Aqueous solution, 0.2M Na 2 MoO 4 The add-on of solution water is as shown in table 1, and all the other reaction raw materials and conditions are similar to embodiment 1.

[0183] The addition of part raw material in the embodiment 2-14 of table 1

[0184]

[0185]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com