Ultra-light fine material continuous pulping equipment and pulping method

A pulping and fine material technology, applied in the direction of separation methods, chemical instruments and methods, mixers, etc., to achieve the effects of reducing dust diffusion, avoiding bag blockage, and no risk of dust explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

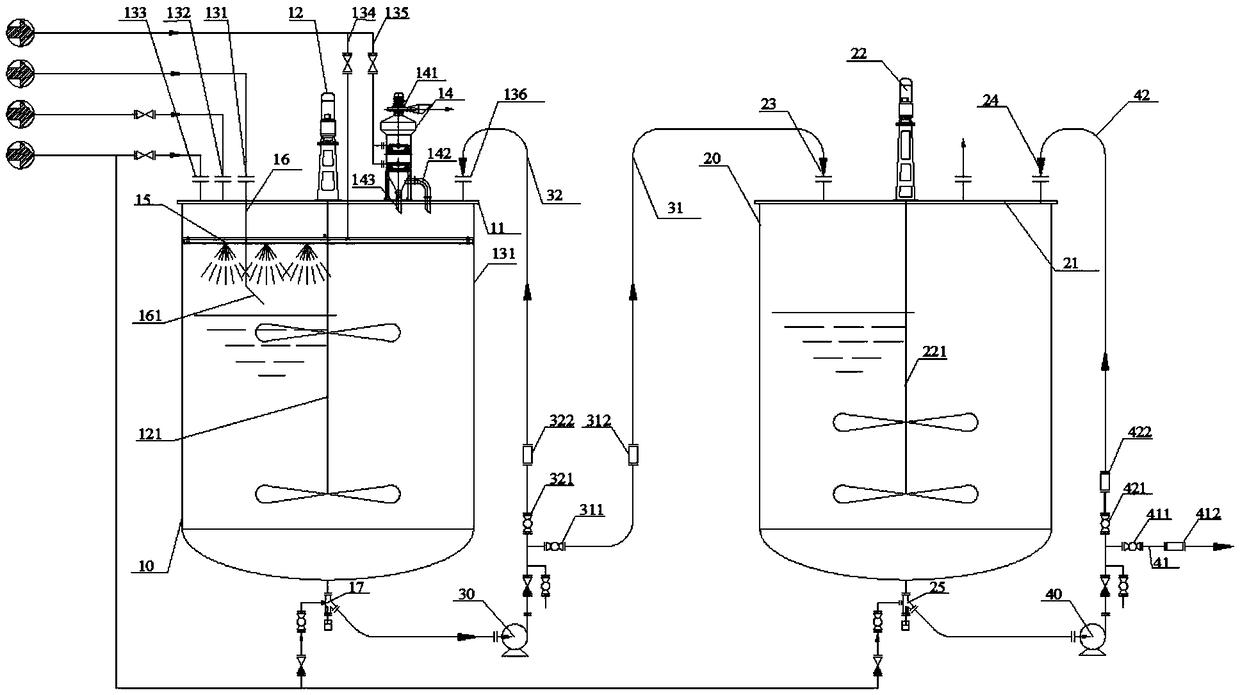

[0043] A continuous pulping equipment for ultra-light fine materials, such as figure 1 Shown, a kind of ultra-light fine material continuous pulping equipment:

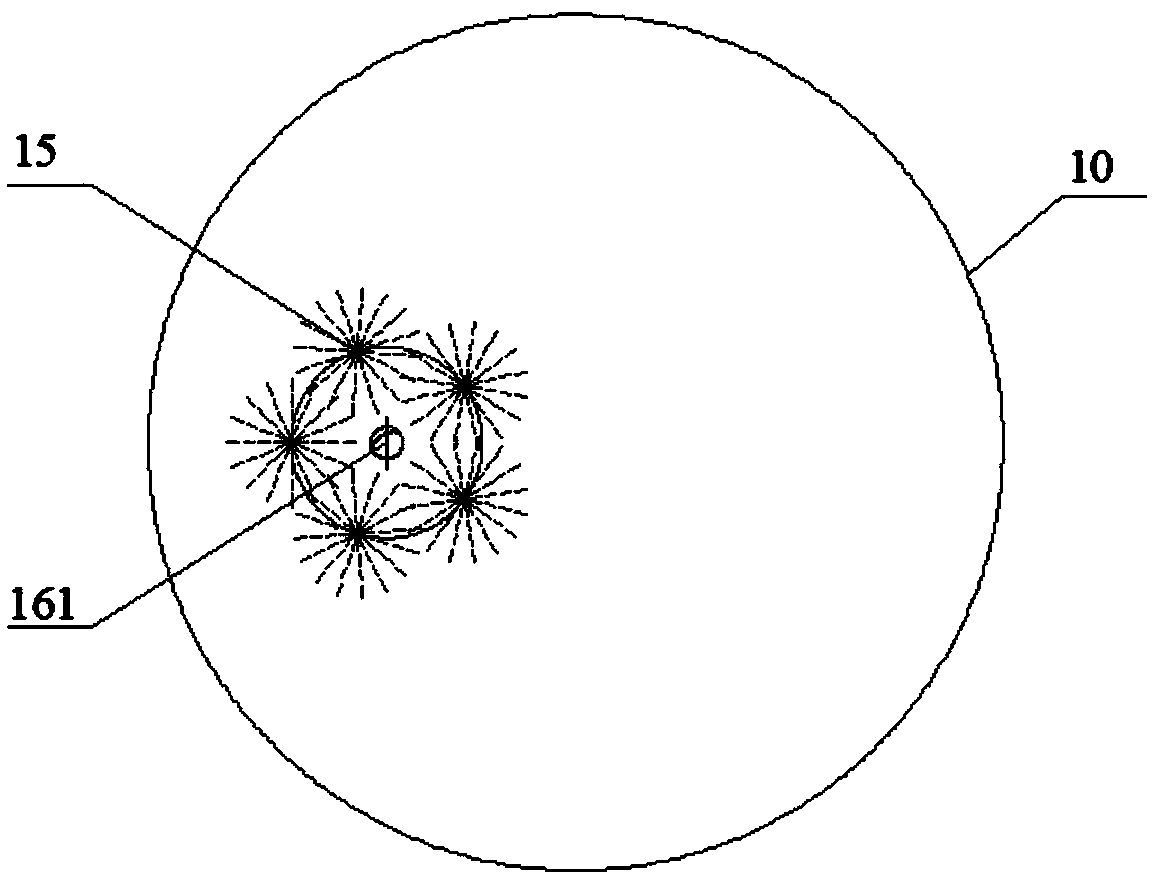

[0044] Including a pulping tank 10, the top of the pulping tank 10 is provided with a top cover I11, the top cover I11 is provided with a stirring motor I12 and a feed port I, and the output shaft of the stirring motor I12 is provided with a stirring blade I121, The mixing paddle I 121 is located in the pulping tank 10. The feed inlet I includes an ultra-light fine material inlet 131, an additive inlet 132, a process water inlet 133, and a feed back inlet I 136; the additive inlet 132 is used to add additives, which can come Adjust the dispersion ability of fine materials in the liquid, and the amount of additives added is selected according to the characteristics of the slurry material.

[0045] The top cover I11 is also provided with a water pipe I134, a water pipe II135, and a water film dust collector 14. The slurry ta...

Embodiment 2

[0055] A continuous pulping method for ultra-light fine materials, such as image 3 Shown: Take the ultra-light fine material continuous pulping equipment in Example 1 as the pulping equipment of this embodiment; take ultra-fine graphite powder pulping as an example; where the pulping tank 10 and the buffer tank 20 in the pulping equipment Effective volume is 30m 3 , High-speed shearing pump 30 delivery capacity 25m 3 / h, the conveying capacity of the centrifugal pump 40 is 20m 3 / h, the qualified finished slurry conveying capacity is 10m 3 / h, specifically including the following steps:

[0056] Step (1): Close valve I311 and open valve II321, and continuously add process water and sodium dodecylbenzene sulfonate solution into the pulping tank 10; the added amount of process water is 7m 3 / h; The mass concentration of the sodium dodecylbenzene sulfonate solution is 25%, and the addition amount of the sodium dodecylbenzene sulfonate solution is 0.5m 3 / h; Get the diluted additive ...

Embodiment 3

[0067] A method for continuous pulping of ultra-light fine materials, such as image 3 Shown: Take the ultra-light fine material continuous pulping equipment in Example 1 as the pulping equipment of this embodiment; use ultra-fine TiO 2 Take pulping as an example; the effective volume of pulping tank 10 and buffer tank 20 in the pulping equipment are both 50m 3 , High-speed shear pump 30 flow 45m 3 / h, centrifugal transfer pump 40 flow rate 35m 3 / h, downstream process throughput 15m 3 / h, specifically including the following steps:

[0068] Step (1): Close valve I311 and open valve II321, and continuously add process water and sodium dodecylbenzene sulfonate solution into the pulping tank 10; the added amount of process water is 13m 3 / h; The mass concentration of the sodium dodecylbenzene sulfonate solution is 15%, and the addition amount of the sodium dodecylbenzene sulfonate solution is 0.5m 3 / h; Get the diluted additive solution;

[0069] Step (2): When the diluted additive so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com