Factory flue gas desulfurization and denitrification device for environment-friendly construction

A factory flue gas and environmental protection technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient utilization of catalysts, low desulfurization and denitrification efficiency, and uneven concentration, so as to avoid uneven deposition concentration , improve contact efficiency, and ensure full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

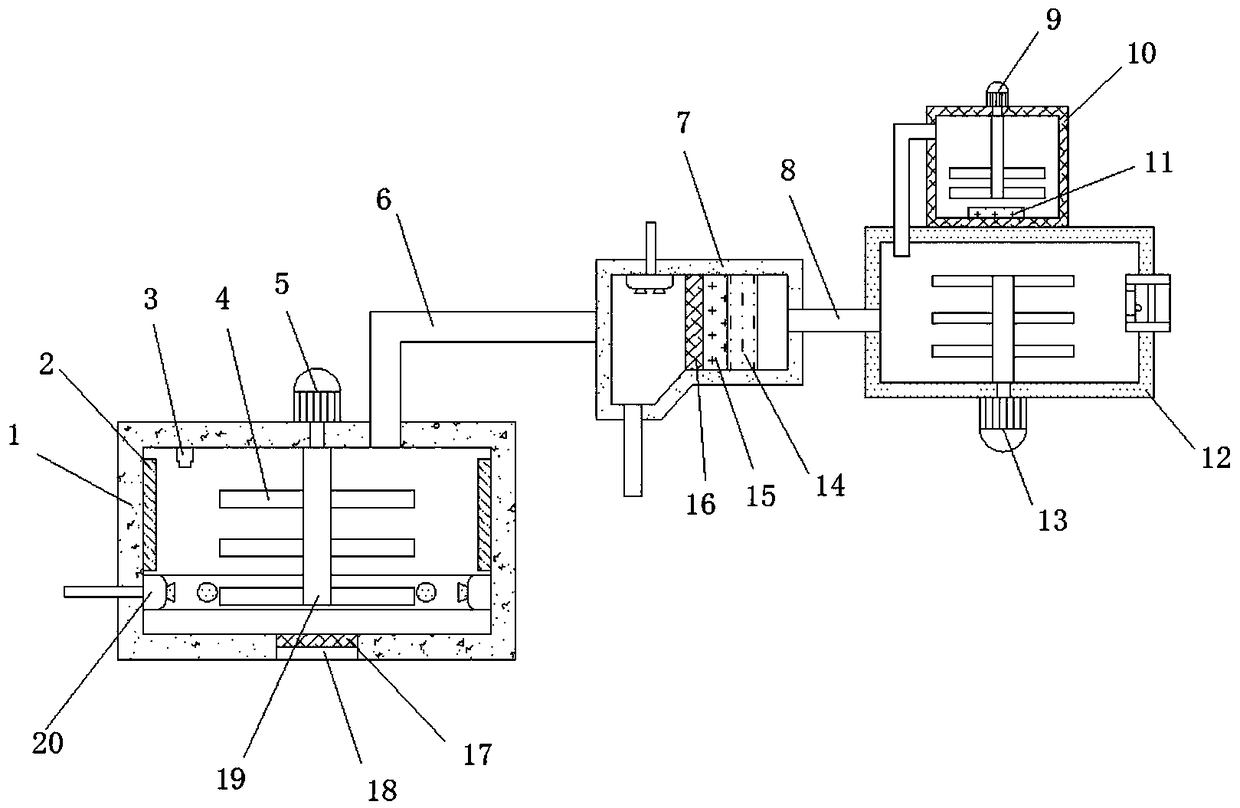

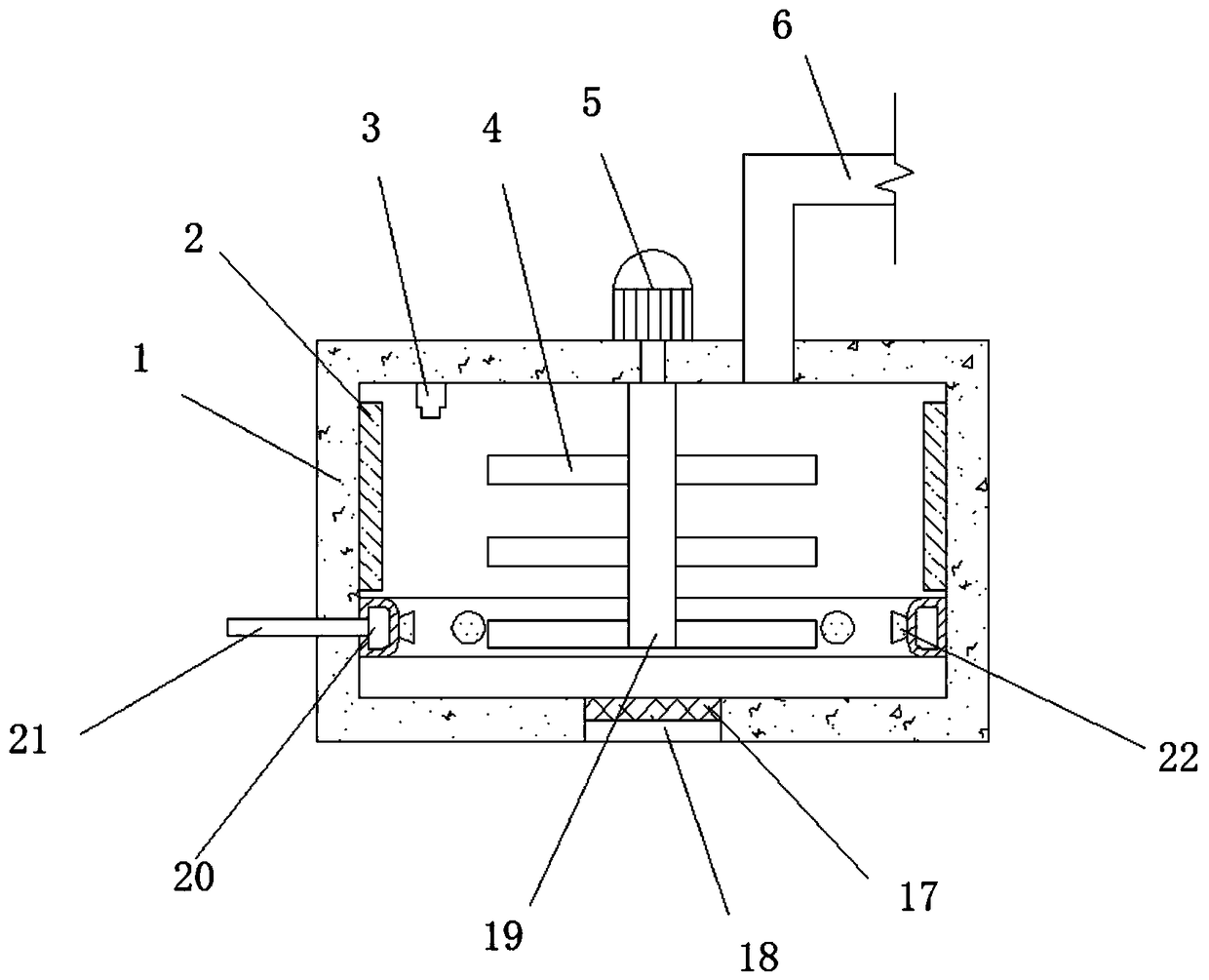

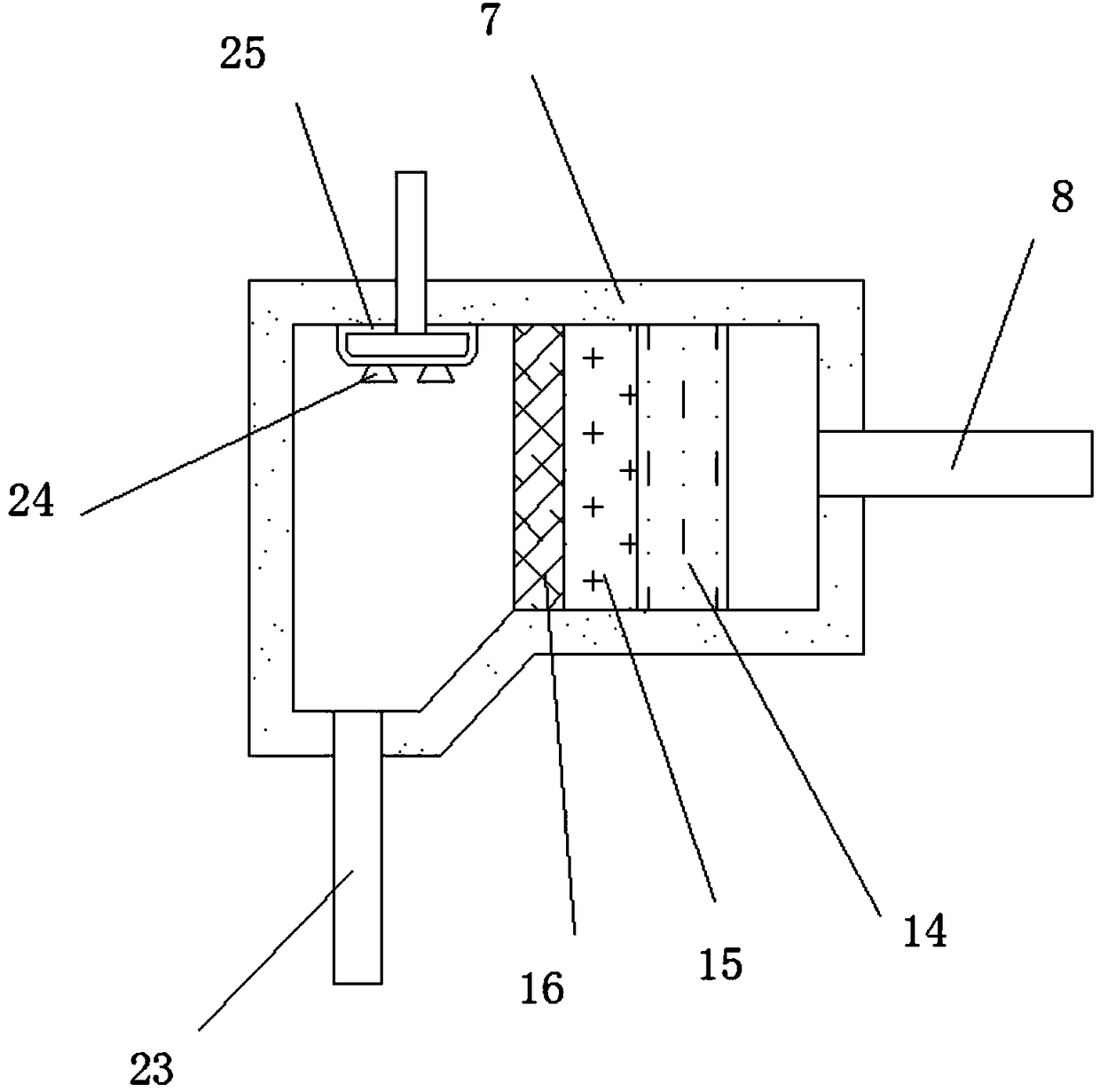

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0025] refer to Figure 1-5 , a factory flue gas desulfurization and denitrification device for environmental protection construction, comprising a denitrification chamber 1, an air inlet 18 is provided at the middle position of the outer wall of the bottom of the denitrification chamber 1, and the top of the inner wall of the air inlet 18 is connected by fastening bolts. The second filter screen plate 17, the bottom of the inner wall around the denitrification chamber 1 is connected with the same transition pipe 20 by fastening bolts, and the outer wall of the transition pipe 20 away from the denitrification chamber 1 is connected with equidistantly distributed ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com