Method for absorbing and purifying ammonia gas in aluminum ash treatment technology

A treatment process and ammonia gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problem of high ammonia content, and achieve the effects of high purity, good separation effect and better filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] A method for absorbing and purifying ammonia in an aluminum ash treatment process, characterized in that it comprises the following steps: a. first passing the mixed gas of ammonia and hydrogen into the waste heat channel; b. waiting for the mixed gas of ammonia and hydrogen to pass through After the waste heat passage, it is introduced into the ammonia absorption and purification system for purification and absorption; c. Finally, the purified hydrogen is sent to the gas mixing station to be mixed with coal gas and used as a fuel for the roaster, and the ammonia liquid that has absorbed ammonia It is sent to the ammonia desulfurization system for reuse.

[0034] Using the waste heat channel to make the particles wrapped in the mixed gas that will react to form impurities react more quickly, reducing the generation of impurities in the subsequent treatment process, and more impurities are generated in the waste heat channel instead of entering the ammonia gas absorption ...

specific Embodiment 2

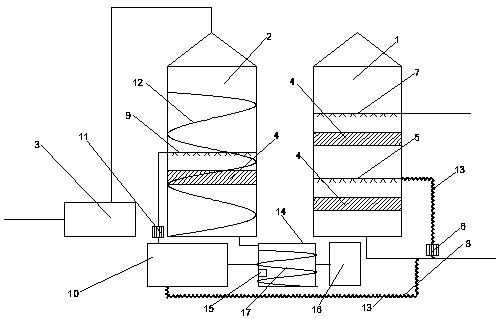

[0035] Such as figure 1As shown, the present embodiment further illustrates the ammonia absorption and purification system on the basis of specific embodiment 1. The ammonia absorption and purification system in the step b includes a primary cooling absorption tower 1, a secondary Absorption tower 2 and dust remover 3, the air inlet and exhaust port of described primary cooling absorption tower 1 are respectively connected with the air outlet of dust remover 3 and the inlet of secondary absorption tower 2 through pipelines, and the air inlet of dust remover 3 The inlet end is connected to the mixed gas inlet pipe, and the packing layer 4 in the inner cavity of the secondary absorption tower 2 has more than two layers, and the spray mechanism set at the lower part of the inner cavity of the secondary absorption tower 2 and used in conjunction with the lowermost packing layer is No. 2 The bottom spraying mechanism 5, the water inlet end of the water supply pipe of the No. 2 bott...

specific Embodiment 3

[0037] In this embodiment, an absorption tower cooling mechanism is added on the basis of the specific embodiment 2, and the absorption tower cooling mechanism is provided outside the tower wall of the first-stage cooling absorption tower 1 .

[0038] Since the ammonia gas will dissolve into the water when the mixed gas is washed, and the ammonia gas will release a certain amount of heat when it dissolves, so the temperature in the primary cooling absorption tower will continue to rise, so the tower of the primary cooling absorption tower The absorption tower cooling mechanism is set outside the wall, which can absorb the heat in the first-level cooling absorption tower, maintain the temperature inside the first-level cooling absorption tower at a reasonable level, and prolong the service life of the first-level cooling absorption tower. There is no absorption tower cooling mechanism on the outer wall of the secondary absorption tower, because clean water enters the secondary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com