Online cleaning device of lower chains of tobacco cutting machine

The technology of cleaning device and shredder is applied in the direction of cleaning device, conveyor objects, transportation and packaging, etc., which can solve the problems of ash receiving board full of materials or smoke, inconvenient cleaning, adhesion of the surface of the chain, etc. To achieve the effect of reducing the incidence of failures, improving work efficiency, and prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

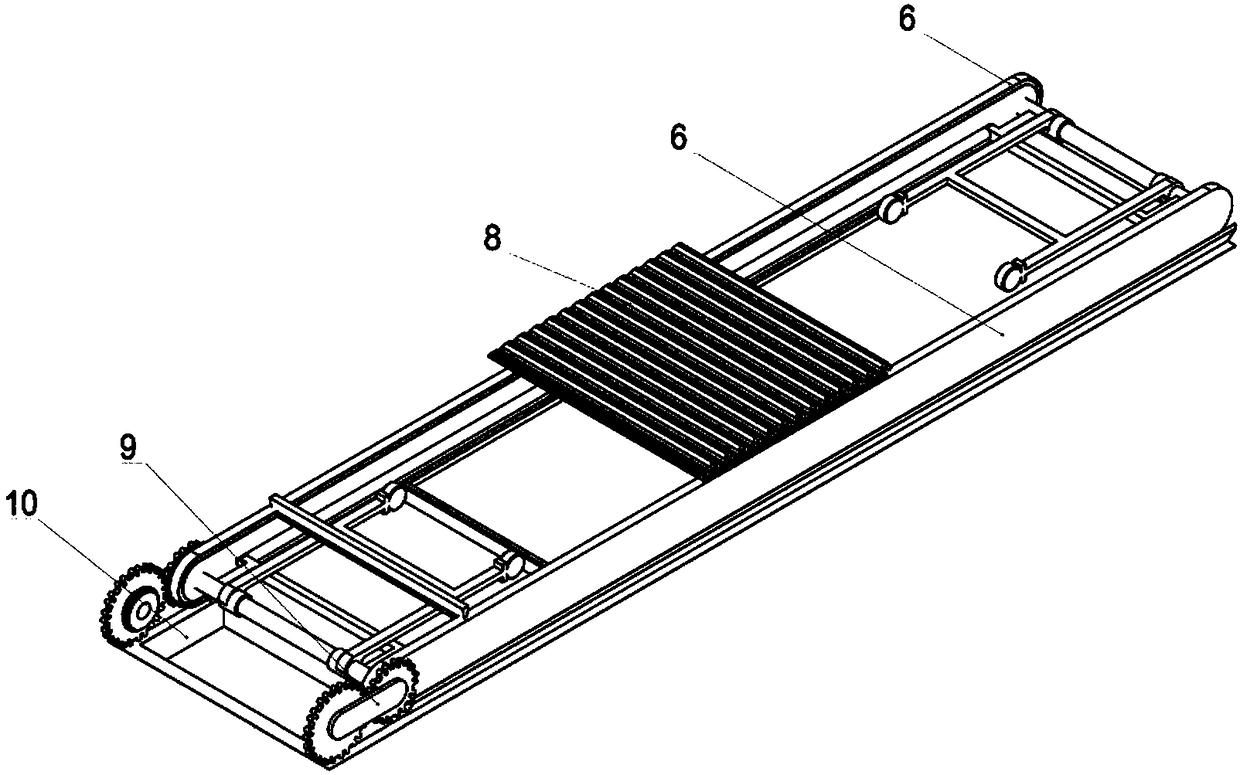

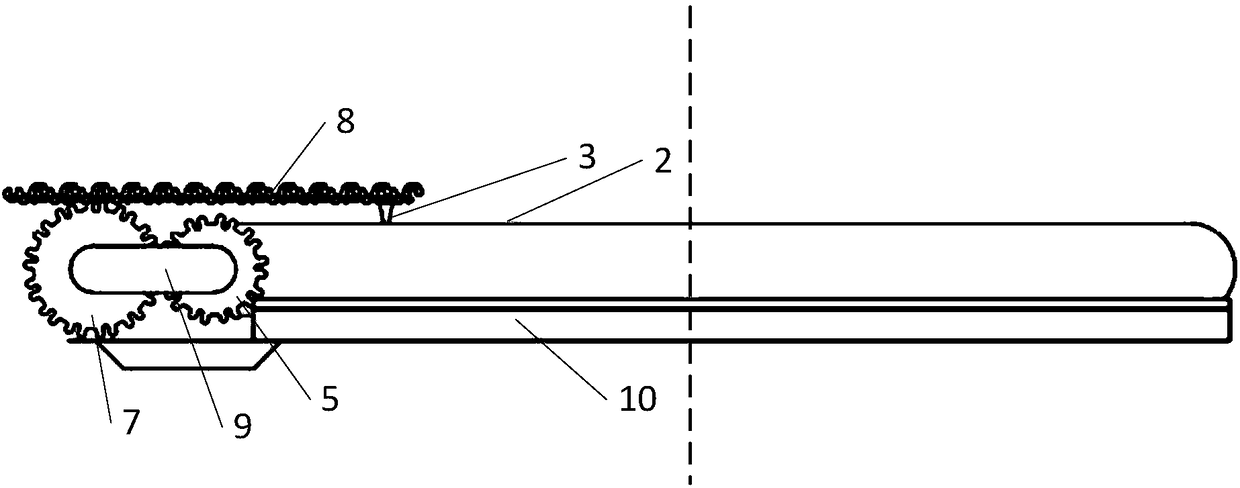

[0028] like figure 1 As shown, in the on-line cleaning device for the lower chain of the shredder described in this embodiment, the driving chain 8 moves the material to the cutting body after compaction. During the movement, the chain 8 drives the driving wheel 7 to rotate, and the driving wheel 7 drives The driven wheel 5 meshed with it rotates, and the driven wheel 5 and the sprocket 4 are riveted or welded, so the driven wheel 5 drives the chain 2 supported by the sprocket 4 to move, and a plurality of cleaning brushes 3 are detachably mounted on the chain 2 surface, and then The chain 2 moves together. When the cleaning brush 3 moves to the upper part of the chain, the moving direction of the cleaning brush 3 is opposite to that of the chain 8, so that it contacts the lower surface of the chain 8 during the movement and cleans the material adhered to the lower surface of the chain 8. to the receiving plate 10 located below the chain 2; at this time, the cleaning brush 3 c...

Embodiment 2

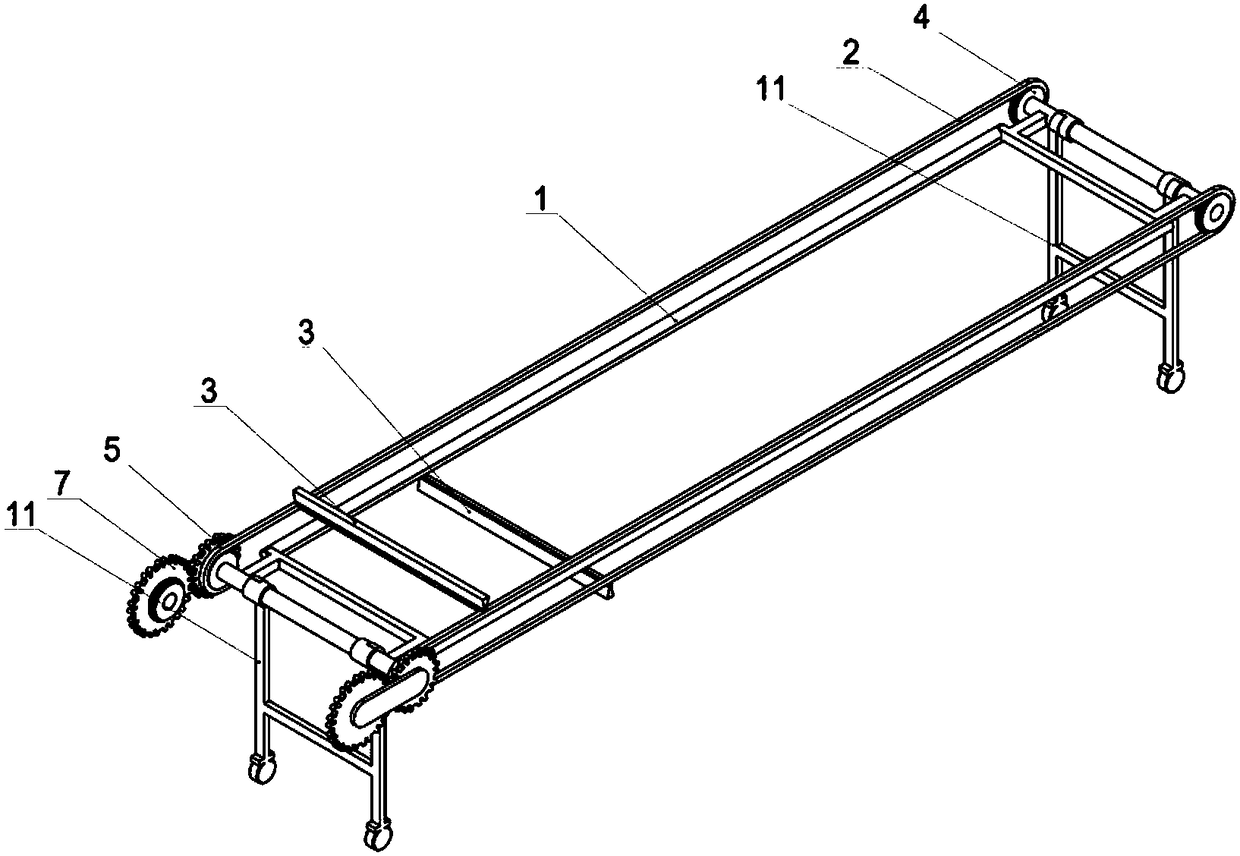

[0031] like figure 2 As shown, in the on-line cleaning device for the lower chain of the shredder described in this embodiment, the surface of the driving wheel 7 is a tooth-shaped structure, which meshes with the external shape of the chain 8 and is driven by the movement of the chain 8. The driving wheel 7 and the driven wheel 5 are provided with driving wheel support 9, and fixing driving wheel 7 guarantees that the axis distance with driven wheel 5 is constant. The sprocket 4, the driven wheel 5 and the cleaning device are all fixed on the frame 1. The material receiving plate 10 is located at the lower part of the cleaning device and fixed on the frame 1. The frame 1 is made of stainless steel to prevent deformation from affecting the cleaning device. .

[0032] The lower end of the frame 1 is connected with a walking support. The four supporting legs 11 of the walking support can be disassembled and folded, and the height can be adjusted and fixed. The angle between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com