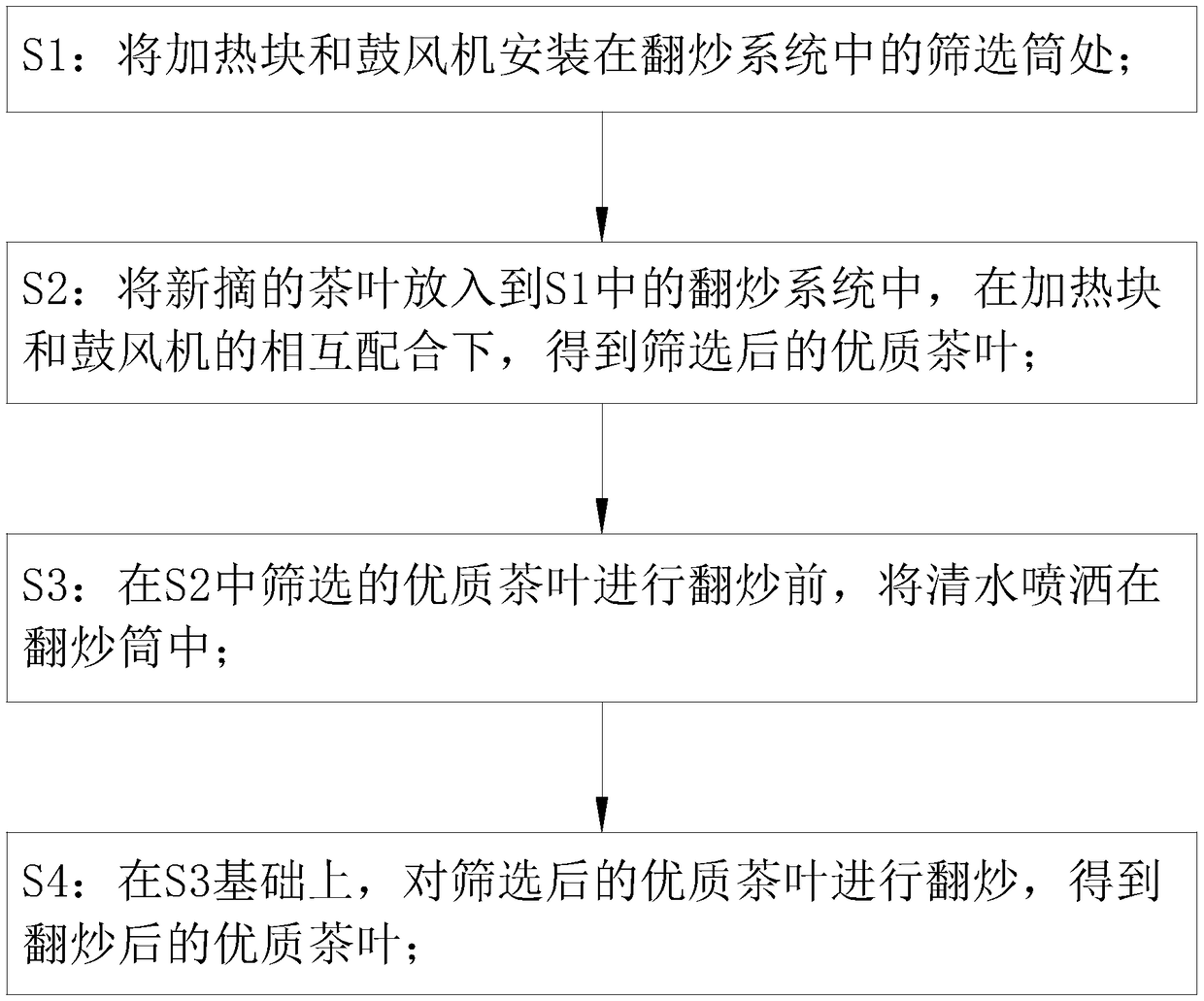

High-quality tea leaf stir-frying method

A high-quality technology for tea leaves, applied in the field of high-quality tea stir-frying, can solve the problems of not being able to stir-fry small-leaf tea leaves and large-leaf tea leaves, insufficient screening, affecting the tea-frying effect, etc., and achieve the effect of improving the stir-frying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

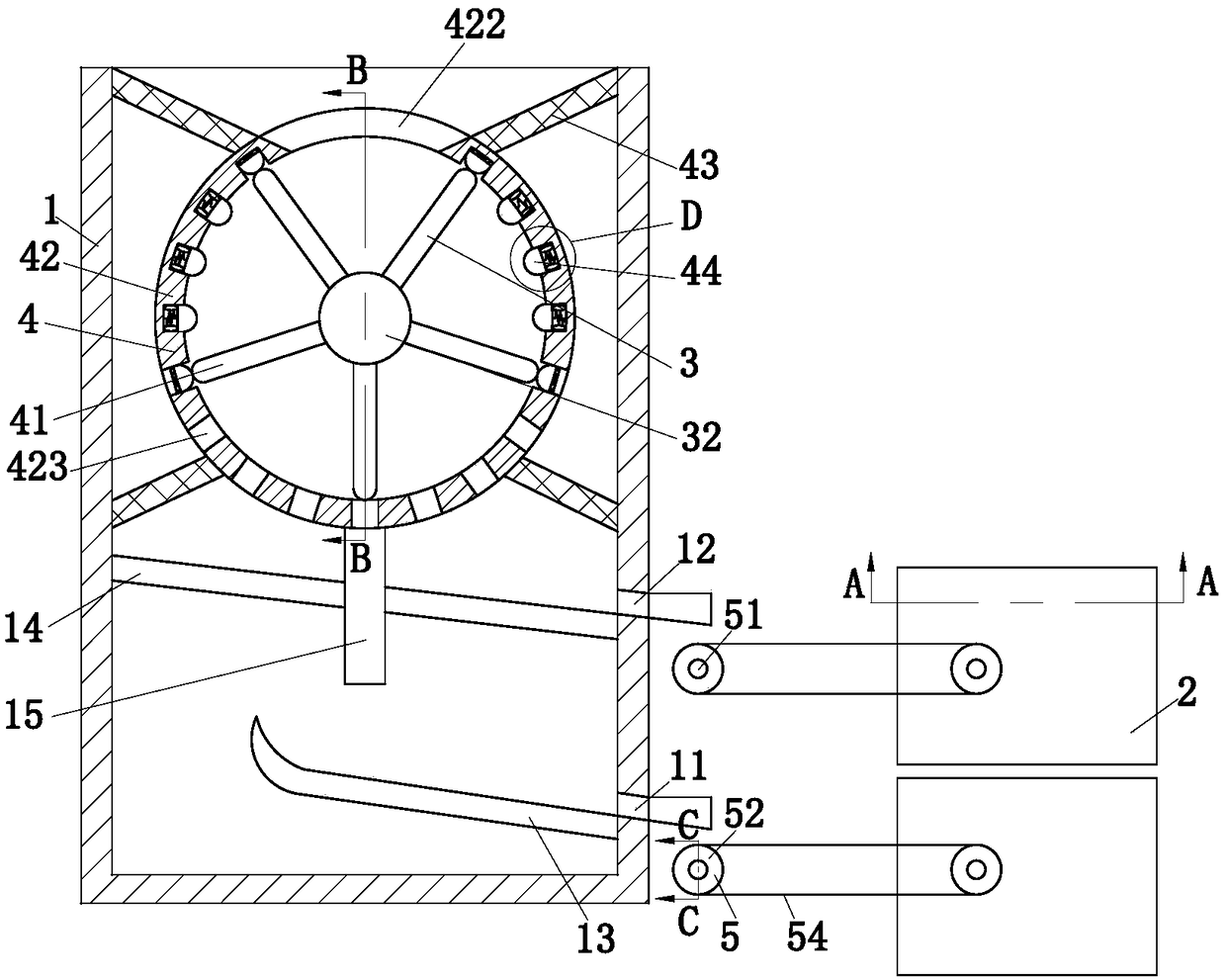

[0060] As an embodiment of the present invention, the end surface of the drive disc 31 is provided with a non-slip layer 311; the non-slip layer 311 is in contact with paraffin, and the non-slip layer 311 is used to increase the friction between the paraffin and the drive disc 31. Since the friction between the liquid paraffin and the drive disc 31 is very small, it affects the screening efficiency of the screening plate 41; the present invention is provided with an anti-skid layer 311, and the anti-skid layer 311 increases the friction between the liquid paraffin and the drive disc 31, so that the drive disc The rapid rotation of 31 improves the screening efficiency of tea leaves by the screening plate 41.

[0061] As an embodiment of the present invention, the sleeve 43 is an elastic sleeve. When the sleeve 43 is a rigid sleeve 43, the screening plate 41 hits the protrusion 44 during rotation, and the protrusion 44 will only move to the side away from the No. 1 shaft 32. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com