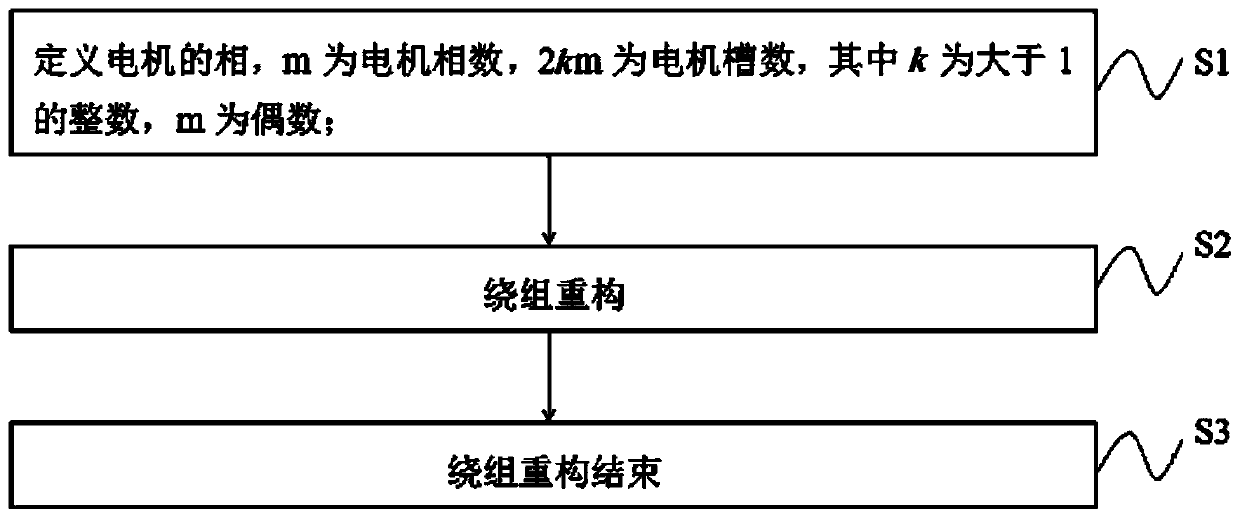

A permanent magnet fault-tolerant rim propulsion motor winding reconstruction method with reduced mutual inductance

A technology of rim propulsion and motor winding, which is applied to the shape/style/structure of the winding conductor to achieve the effects of reducing the thickness of the slot, reducing the mutual inductance, and reducing the leakage inductance of the slot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

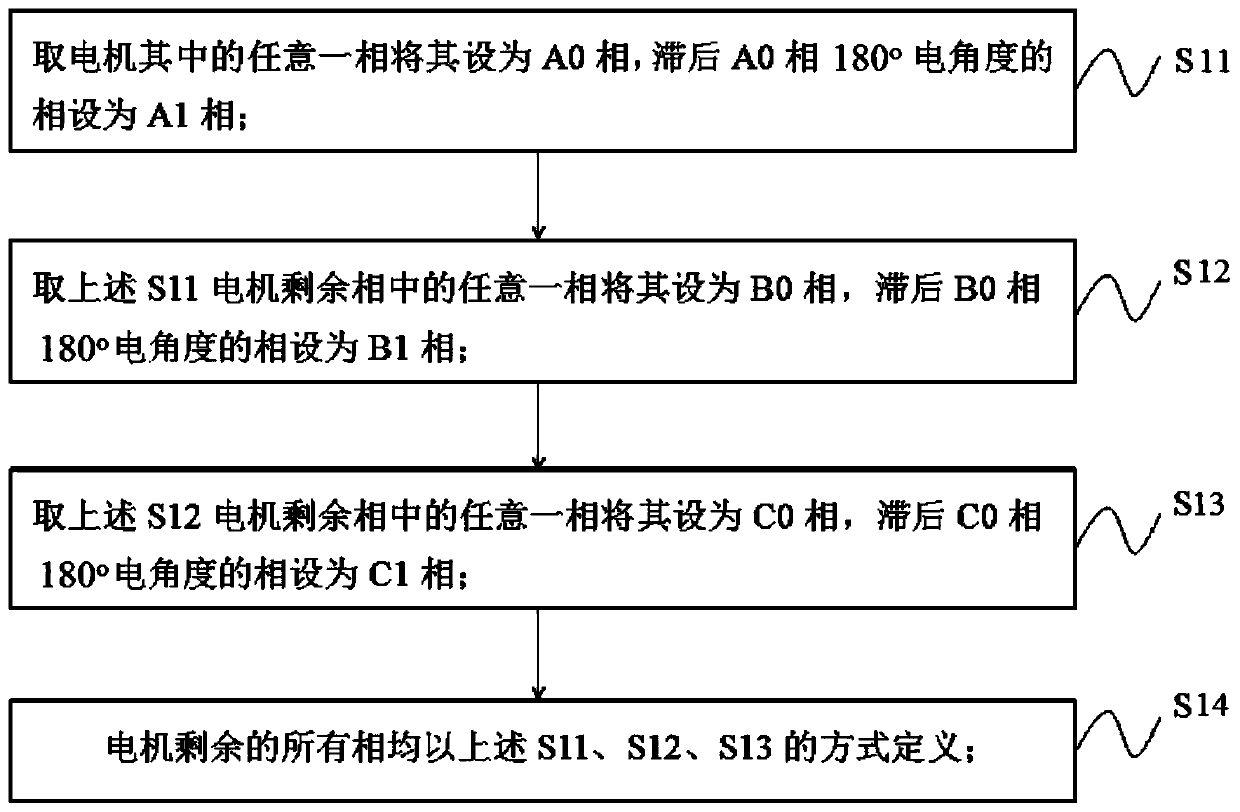

[0048] 36-slot 30-pole forward winding double Y-shift 60° symmetrical six-phase permanent magnet fault-tolerant rim propulsion motor

[0049] The winding structure before reconstruction is as Figure 4 As shown, the six-phase windings are A, B, C, U, V, W respectively. Take the winding of phase A as a reference, set it as phase A0, and the phase lagging behind phase A by 180° in electrical angle is phase V and set it as phase A1.

[0050] For the remaining phases B, C, U, and W, take phase B as a reference and set it as phase B0, and the phase that lags phase B by 180° in electrical angle is phase W and set it as phase B1.

[0051] For the remaining C and U phases, take the C phase as a reference and set it as the C0 phase, and the U phase that lags the C phase by 180° electrical angle is the U phase and set it as the C1 phase. All phase definitions are complete.

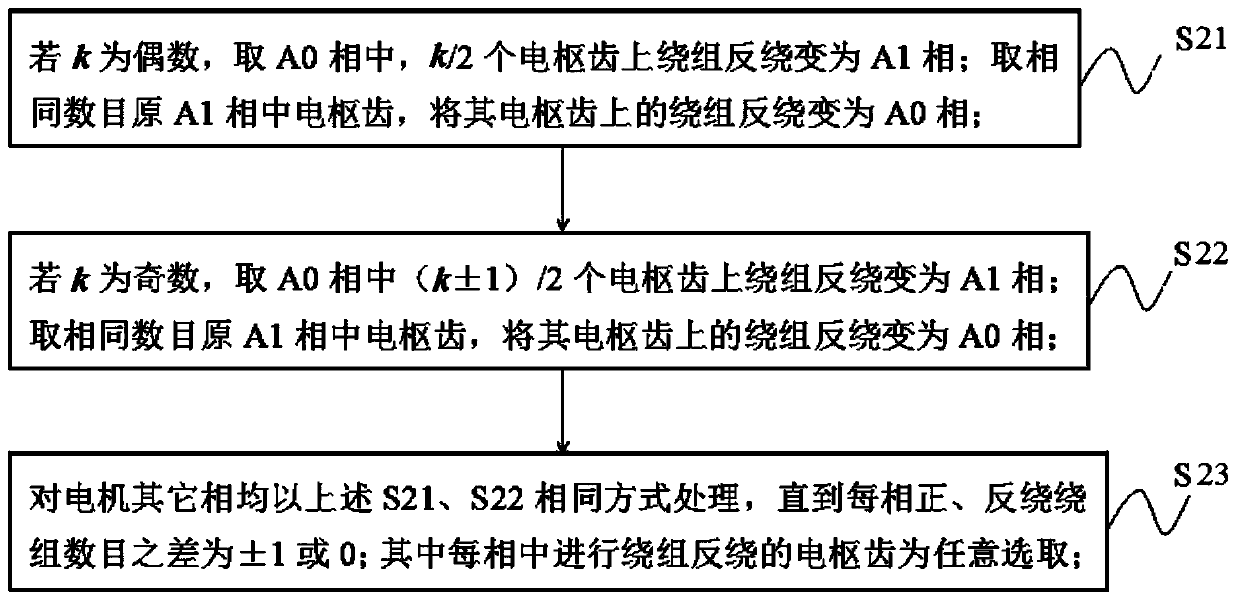

[0052] The number of motor slots is 2km, that is, 36 slots, where m is 6, and k is 3.

[0053] k is an odd numb...

Embodiment 2

[0061] 48-slot 40-pole forward winding double Y-shift 60° symmetrical six-phase permanent magnet fault-tolerant rim propulsion motor:

[0062] Restructure the front winding structure as Figure 9 As shown, the six-phase windings are A, B, C, U, V, W respectively. Take the winding of phase A as a reference, set it as phase A0, and the phase lagging behind phase A by 180° in electrical angle is phase V and set it as phase A1.

[0063] For the remaining phases B, C, U, and W, take phase B as a reference and set it as phase B0, and the phase that lags phase B by 180° in electrical angle is phase W and set it as phase B1.

[0064] For the remaining C and U phases, take the C phase as a reference and set it as the C0 phase, and the U phase that lags the C phase by 180° electrical angle is the U phase and set it as the C1 phase. All phase definitions are complete.

[0065] The number of motor slots is 2km, that is, 48 slots, where m is 6, and k is 4.

[0066] k is an even numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com