Preparation and encapsulation method of a low-temperature fast-bonding pre-sintered nano-network silver film

A nano-network and fast connection technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inapplicability to large-scale applications, high prices, and low output, and achieve low production input costs, simple equipment, The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

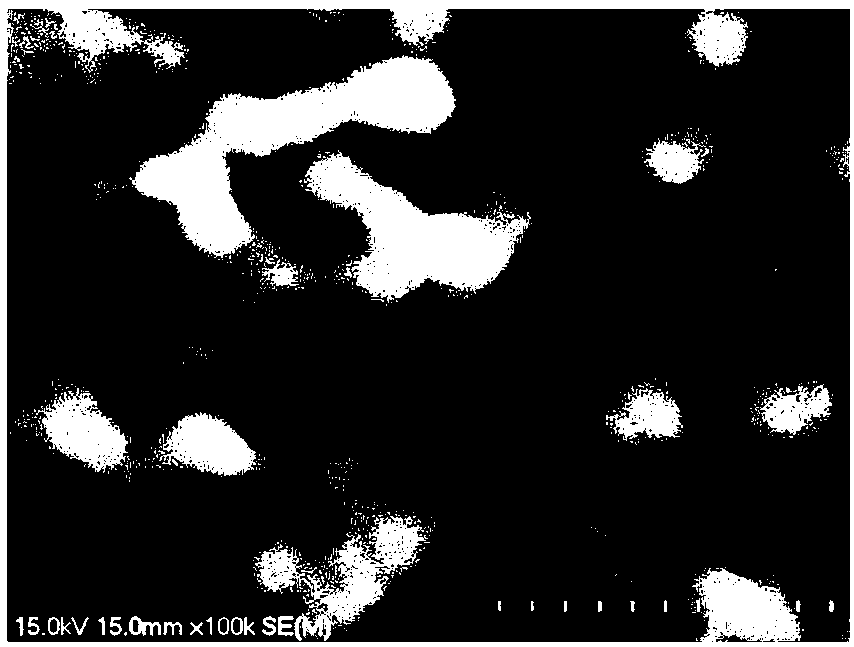

Image

Examples

Embodiment 1

[0029] Embodiment 1 A method for preparing a pre-sintered network silver film that can be quickly connected at low temperature, comprising:

[0030] (S1): Prepare sodium citrate-coated silver particles with a size of 20 nm. The temperature of the solution prepared by the coating layer is 60°C, the reaction time is 5min, and the mass ratio of the coating layer to nano-silver is 1:1;

[0031] (S2): The nano-silver particles with a coating layer on the surface are dissolved in ethylene glycol using ultrasonic stirring, the mass fraction ratio is 1:5, and flocculation, centrifugation, and flocculation are carried out using an ethylene glycol solution containing saturated sodium chloride. The time is 3min, the centrifugal speed is 3000r / min, the centrifugal time is 5min, A:B=3:1, after the above method is repeated 4 times, the nano-silver precipitation after the chemical shearing of the coating layer is obtained;

[0032](S3): The obtained nano-silver precipitation is fully mechan...

Embodiment 2

[0034] Embodiment 2 A kind of preparation method of the pre-sintered network silver film that can be connected quickly at low temperature, comprising:

[0035] (S1): Prepare sodium citrate-coated silver particles with a size of 50 nm. The temperature of the solution prepared by the coating layer is 60°C, the reaction time is 5min, and the mass ratio of the coating layer to nano-silver is 1:1;

[0036] (S2): The nano-silver particles with a coating layer on the surface are dissolved in 1-2 propylene glycol using ultrasonic stirring, the mass fraction ratio is 1:9, and flocculation and centrifugation are carried out using 1-2 propylene glycol solution containing saturated sodium carbonate, The flocculation time is 3min, the centrifugal speed is 3000r / min, the centrifugal time is 5min, A:B=1:1, after repeating the above method 3 times, the nano-silver precipitation after the chemical shearing of the coating layer is obtained;

[0037] (S3): The obtained nano-silver precipitation...

Embodiment 3

[0039] Embodiment 3 A method for preparing a pre-sintered network silver film that can be quickly connected at low temperature, comprising:

[0040] (S1): the preparation size is the silver particle of coating PVP of 70nm, the solution temperature prepared by coating layer is 60 ℃, and the reaction time is 5min, and the mass ratio of coating layer and nano-silver is 1:1;

[0041] (S2): The nano-silver particles with a coating layer on the surface are dissolved in glycerol using ultrasonic stirring, the mass fraction ratio is 1:6, and the glycerol solution containing saturated sodium sulfate is used to flocculate and centrifuge it, and the flocculation time For 3min, the centrifugal speed is 3000r / min, the centrifugal time is 5min, A:B=4:1, after the above-mentioned method is repeated 5 times, the nano-silver precipitation after the chemical shearing of the coating layer is obtained;

[0042] (S3): The obtained nano-silver precipitation is fully mechanically mixed with methyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com