Method for testing shuttle effect of accelerated polysulfide

A shuttle effect, polysulfide technology, applied in the field of lithium-sulfur battery separator and electrochemistry, can solve the problems of cumbersome, complex, acceleration, etc., to achieve the effect of accelerated shuttle effect, simple steps, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Sodium polysulfide aqueous solution and Na 2 SO 4 Aqueous solution equipment:

[0026] Na 2 S+xS=Na 2 S (x+1) , from this reaction equation we can know that by controlling Na 2 The molar ratio of S to elemental sulfur to obtain different polysulfides, expressed as Na 2 S 6 For example, at this time Na 2 The molar ratio of S to S is 1:5. Add 300mL of deionized water into a 500mL three-necked flask, feed nitrogen, and weigh Na 2 S.9H 2 O (12g, 0.05mol) was then added, stirred at room temperature until Na 2 S.9H 2 O is completely dissolved; then the temperature is raised to 50 degrees, and S (8g, 0.25mol) is added under the protection of nitrogen, dissolved and stirred until it is completely dissolved, cooled to room temperature, and the solution at this time is 1mol / L Na 2 S 6 aqueous solution.

[0027] Weigh Na 2 SO 4 (28.404g, 0.2mol), join in the beaker of 500mL, add the deionized water of 200mL subsequently, stir until the solid substance dissolves...

Embodiment 2

[0032] (1) Sodium polysulfide aqueous solution and Na 2 SO 4 The equipment of aqueous solution: consistent as in embodiment one

[0033] (2) Construction of electrolysis device

[0034] Buy a U-shaped electrolytic cell online, separate the positive and negative electrodes with a modified PP diaphragm in the middle, and fix them with clips to prevent the electrolyte from flowing out. Add 1mol / L Na to the left 2 S 6 The aqueous solution is used as the negative electrode, the liquid level needs to be higher than the height of the diaphragm, and 1mol / L Na is added to the right 2 SO 4 The aqueous solution is used as the positive electrode, and the liquid level also needs to be higher than the height of the diaphragm.

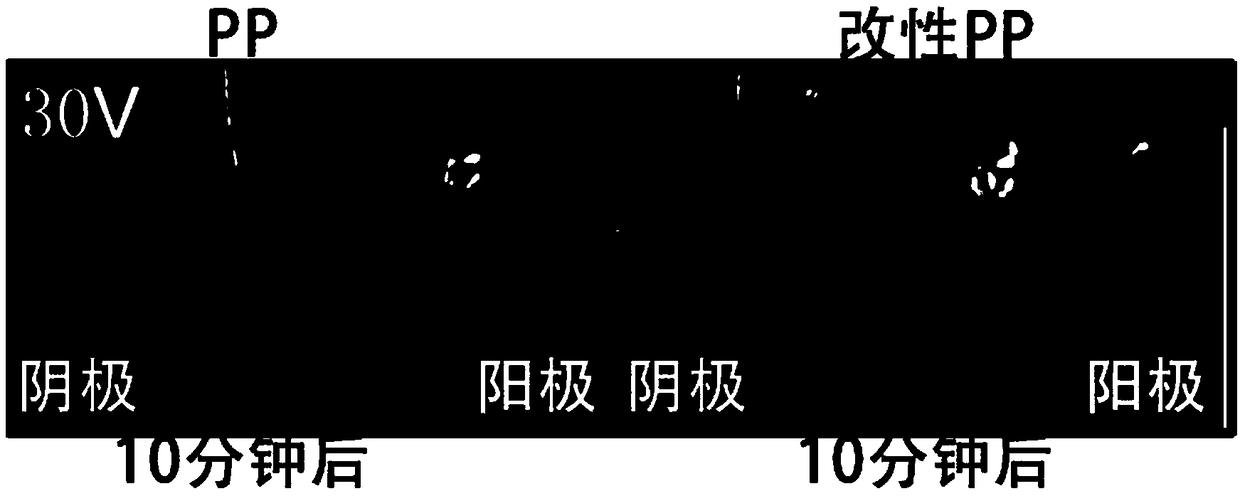

[0035] Apply a constant voltage of 30V to the battery, and monitor the change of its current value at any time. The polysulfide ions will pass through the diaphragm to the positive electrode, so that the electrolytic cell on the right side will turn yellow, and ...

Embodiment 3

[0037] (1) Sodium polysulfide aqueous solution and Na 2 SO 4 The equipment of aqueous solution: consistent as in embodiment one

[0038] (2) Construction of the electrolysis device:

[0039] Buy a U-shaped electrolyzer online, separate the positive and negative electrodes with a PP diaphragm in the middle, and fix them with clips to prevent the electrolyte from flowing out. Add 1mol / L Na to the left 2 S 6 The aqueous solution is used as the negative electrode, the liquid level needs to be higher than the height of the diaphragm, and 1mol / LNa is added to the right 2 SO 4 The aqueous solution is used as the positive electrode, and the liquid level also needs to be higher than the height of the diaphragm.

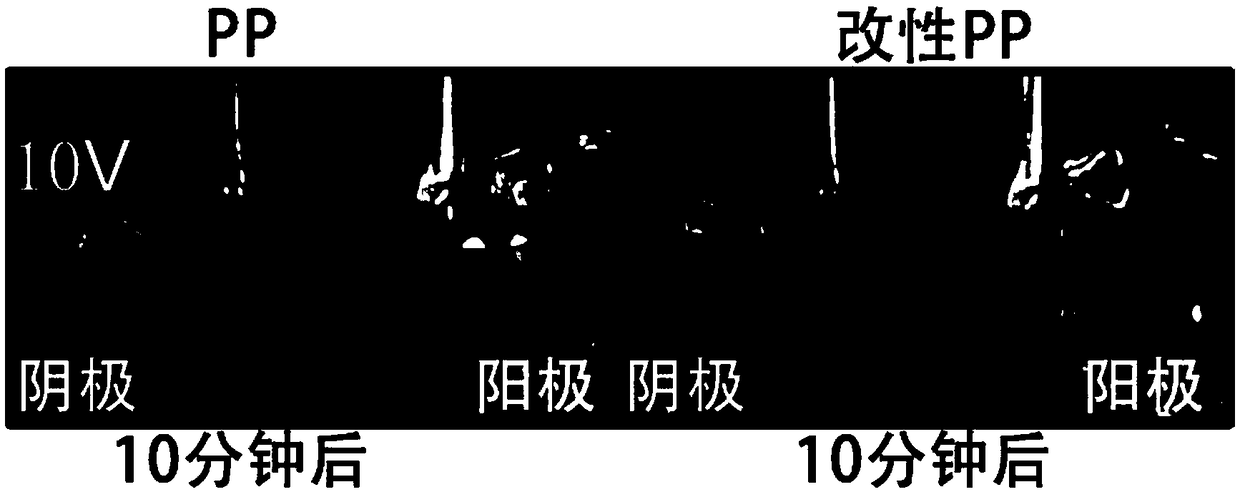

[0040] Apply a constant voltage of 10V to the battery, and monitor the change of its current value at any time. The polysulfide ions will pass through the diaphragm to the positive electrode, so that the electrolytic cell on the right side will turn yellow, and at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com