Preparation method of silicon-aluminum ZSM-22 molecular sieve with controllable grain size

A technology of crystal grain size and molecular sieve, applied in the directions of crystalline aluminosilicate zeolite, molecular sieve and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of complex synthesis steps, low product yield, etc. The effect of simplifying experimental steps and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, silica sol, Al 2 SO 4 , 1,6-hexanediamine, potassium hydroxide, and deionized water are mixed according to the following molar ratio to form an initial gel mixture, silica sol (as SiO 2 Count): Al 2 SO 4 (in Al 2 o 3 Total): 1,6-Hexamethylenediamine: Potassium Hydroxide: Deionized Water = 1:0.0125:0.1:0.2:30. The obtained mixture was placed in a reaction kettle lined with polytetrafluoroethylene, and after dynamic crystallization at a speed of 40 rpm at 150 ° C for 10 h, it was taken out and cooled, and KOH, K + / SiO 2 The molar ratio is 0.02:1. After stirring for 2 hours, secondary crystallization at 150°C at 40 rpm for 24 hours under autogenous pressure. After the crystallization is complete, the product is filtered and washed until neutral, dried and calcined to obtain a silica-alumina molecular sieve. Wherein, the calcination temperature is 600° C., and the calcination time is 10 h.

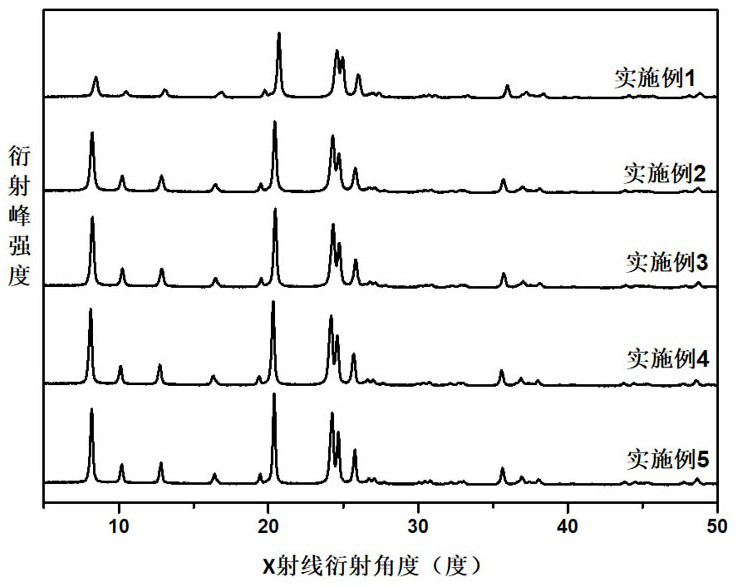

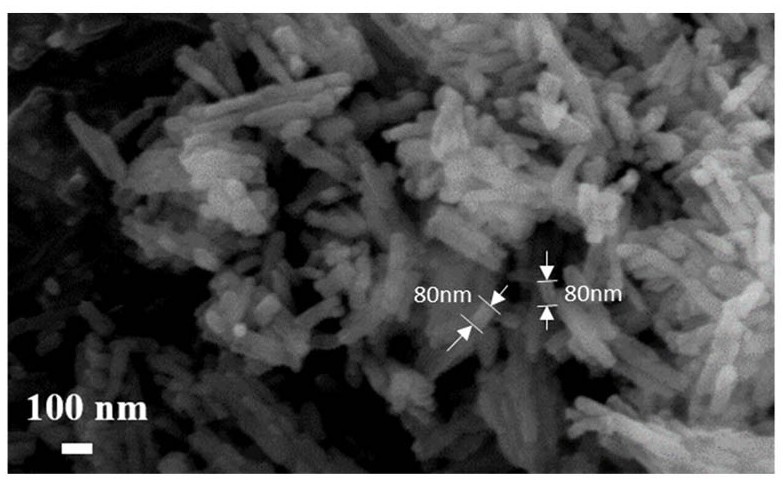

[0039] Its structure is ZSM-22 zeolite molecular sieve by X-ray di...

Embodiment 2

[0042] First, silica sol, Al 2 SO 4, 1,6-hexanediamine, potassium hydroxide, and deionized water are mixed according to the following molar ratio to form an initial gel mixture, silica sol (as SiO 2 Count): Al 2 SO 4 (in Al 2 o 3 Total): 1,6-Hexamethylenediamine: Potassium Hydroxide: Deionized Water = 1:0.0125:0.2:0.2:30. The obtained mixture was placed in a reaction kettle lined with polytetrafluoroethylene, and after dynamic crystallization at a speed of 40 rpm at 160°C for 12 hours, it was taken out and cooled, and HNO was added 3 solution, H + / SiO 2 The molar ratio is 0.02:1. After stirring for 2 hours, secondary crystallization was performed at 160°C at 40 rpm for 24 hours under autogenous pressure. After the crystallization was completed, the product was filtered and washed until neutral, dried and calcined to obtain a silica-alumina molecular sieve. Wherein, the calcination temperature is 600° C., and the calcination time is 10 h.

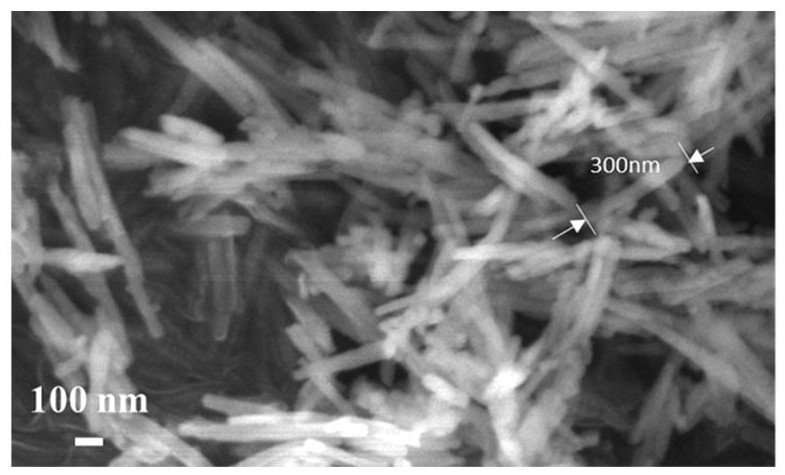

[0043] Its structure is ZS...

Embodiment 3

[0046] First, silica sol, Al 2 SO 4 , 1,6-hexanediamine, potassium hydroxide, and deionized water are mixed according to the following molar ratio to form an initial gel mixture, silica sol (as SiO 2 Count): Al 2 SO 4 (in Al 2 o 3 Total): 1,6-Hexamethylenediamine: Potassium Hydroxide: Deionized Water = 1:0.015:0.2:0.2:40. The obtained mixture was placed in a reaction kettle lined with polytetrafluoroethylene, and after dynamic crystallization at a speed of 40 rpm at 160 °C for 10 h under autogenous pressure, it was taken out and cooled, and H 2 SO 4 solution, H + / SiO 2 The molar ratio is 0.06:1. After stirring for 2 hours, the secondary crystallization is carried out at 160°C at a speed of 40 rpm for 28 hours under autogenous pressure. After the crystallization is completed, the product is filtered and washed until neutral, dried and calcined to obtain a silica-alumina molecular sieve. Wherein, the calcination temperature is 500° C., and the calcination time is 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com