Method for monitoring leakage at joints of underground diaphragm wall

A technology for underground diaphragm walls and joints, which can be used in directions such as detecting the presence of fluid at leak points, testing fluid tightness with electrical devices, and measuring liquid tightness with liquid/vacuum degrees. The impact of stable use, the inability to monitor the leakage of underground diaphragm walls, and the low detection accuracy and accuracy have achieved the effects of increasing detection accuracy and accuracy, reducing construction costs, and improving excavation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below.

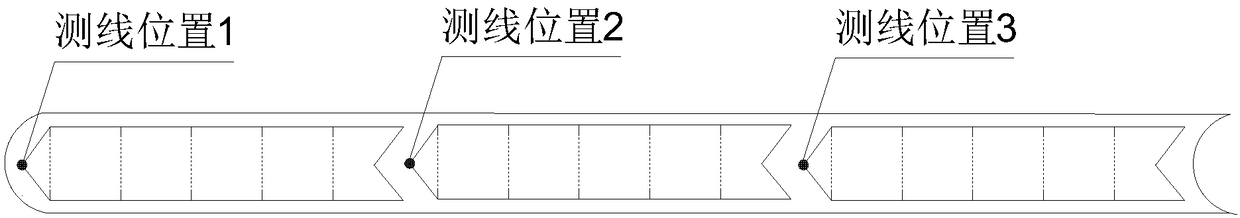

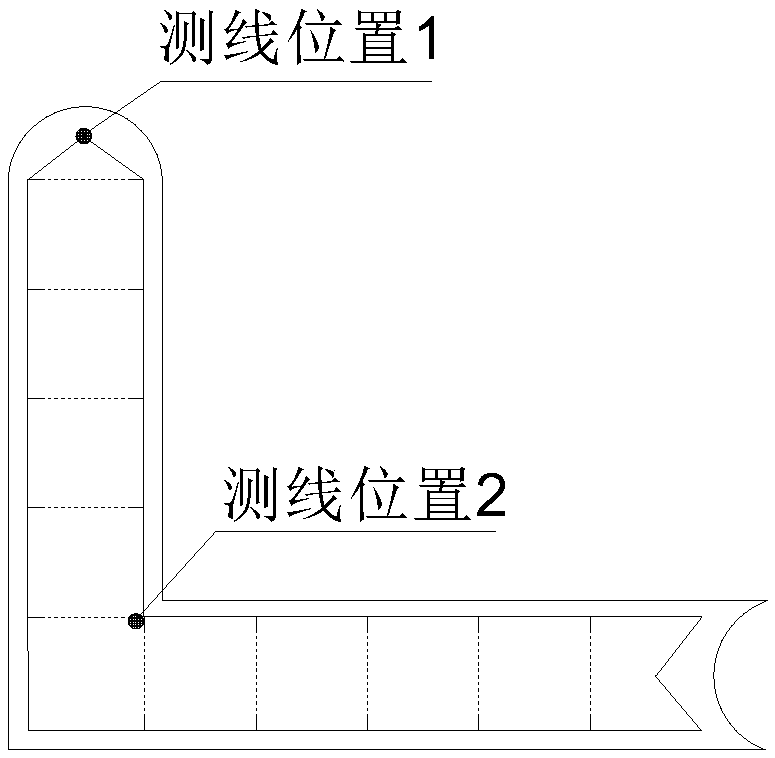

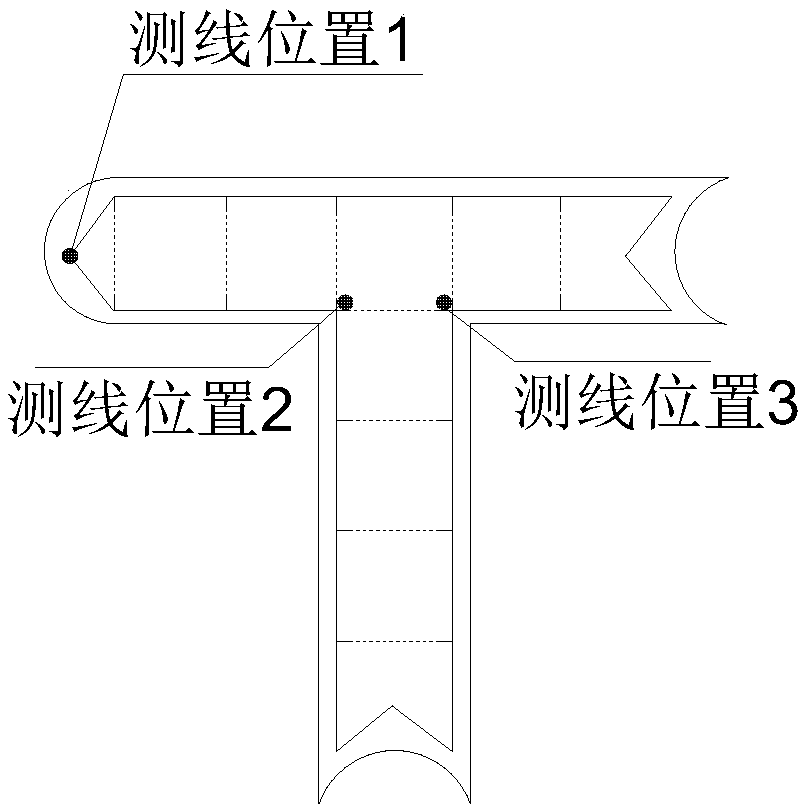

[0024] Such as Figure 1 to Figure 5 As shown, the specific steps of the present invention are:

[0025] A. Determine the shape of the reinforcement cage of the diaphragm wall according to the construction type of the diaphragm wall, and then lay out electrode measuring lines at the joints and corners of the diaphragm wall;

[0026] B. Each electrode measuring line is laid longitudinally along the underground continuous wall at the laying position, and the electrode measuring line is fixed on the steel cage of the underground continuous wall by insulating tape;

[0027] C. Set up 48 electrode measurement points on each electrode survey line, and the distance between adjacent electrode survey points on part of the electrode survey line in the aquifer is 0.25m, and the remaining part of the electrode survey line is adjacent The distance between the electrode measuring points is 0.5m; the electrode measuring line used is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com