Electric steering device transmission for rear-view mirror of car

A technology of electric steering gear and car rearview mirror, applied in the directions of instruments, vehicle parts, installation, etc., can solve the problems of over-the-top, different friction, and the slippage mechanism cannot work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

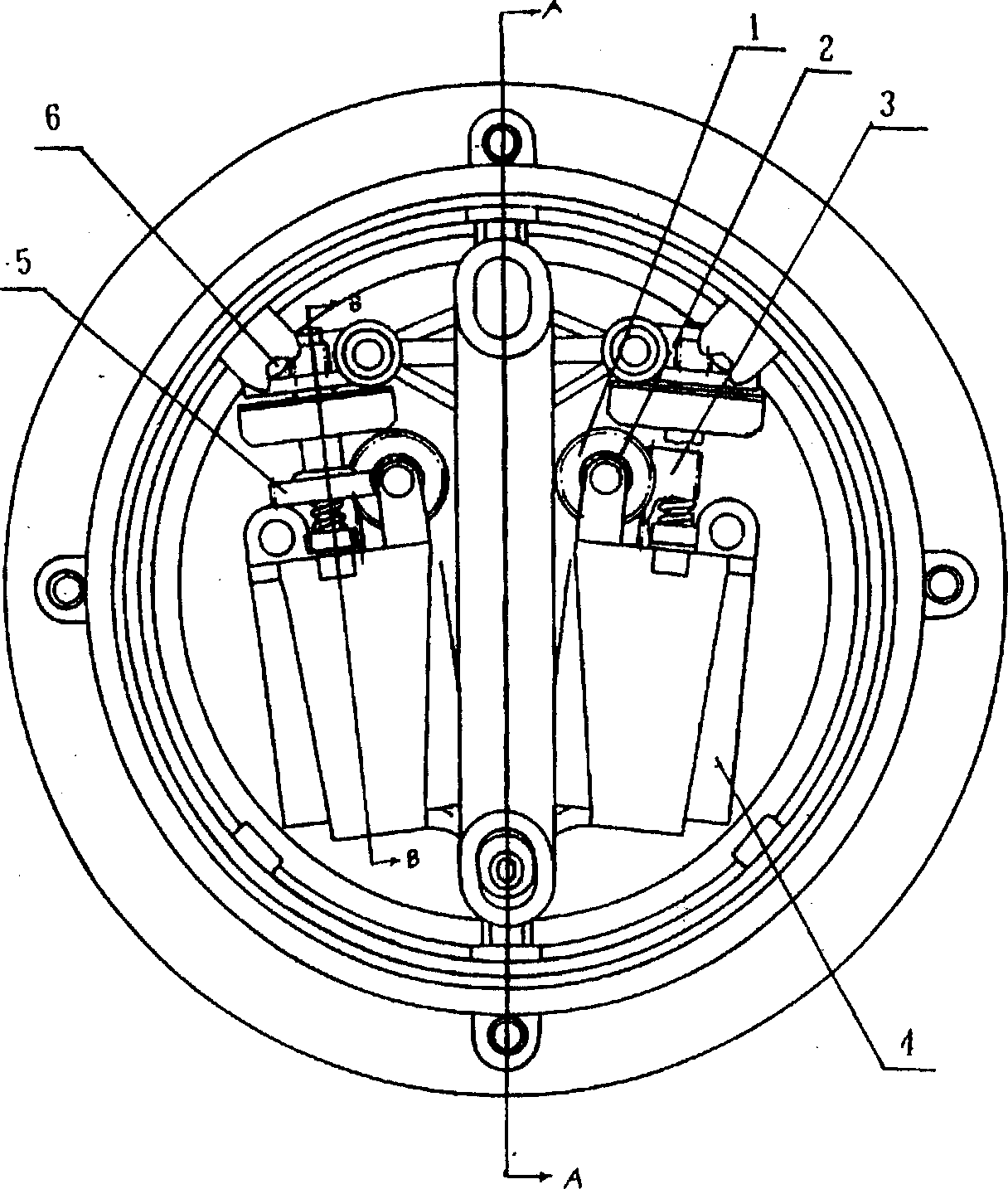

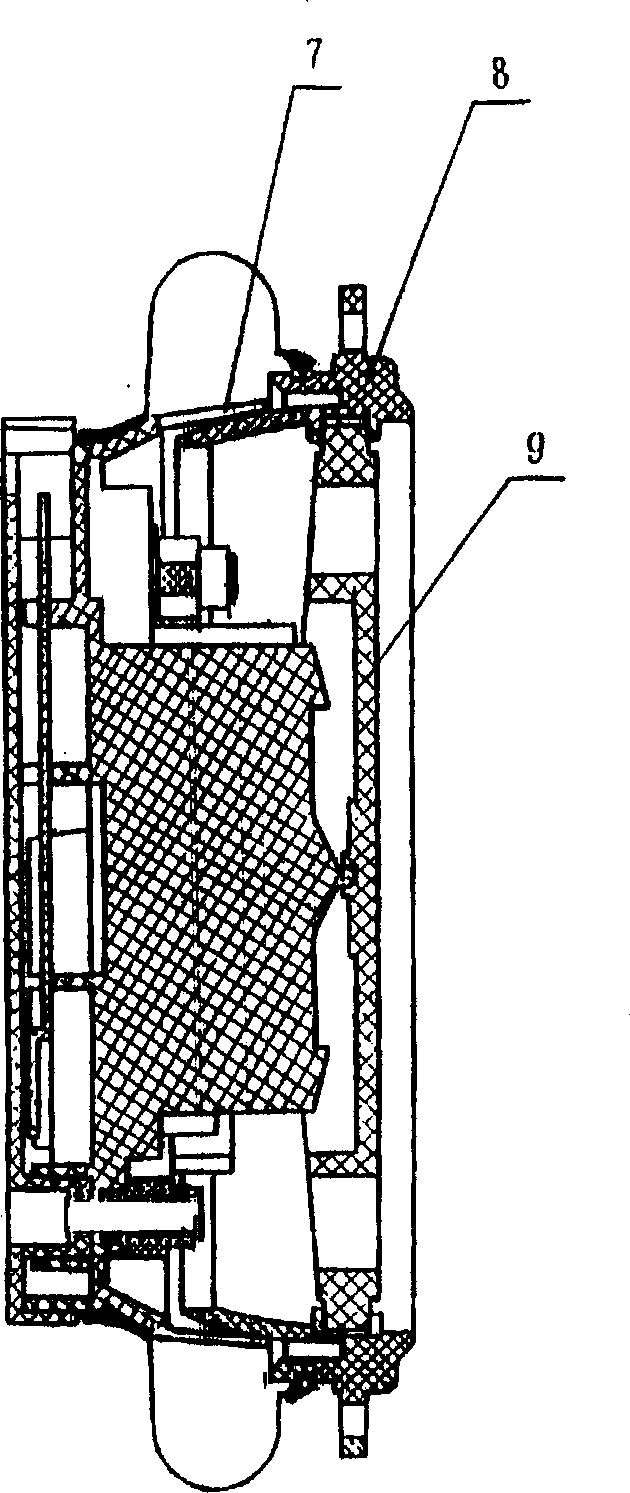

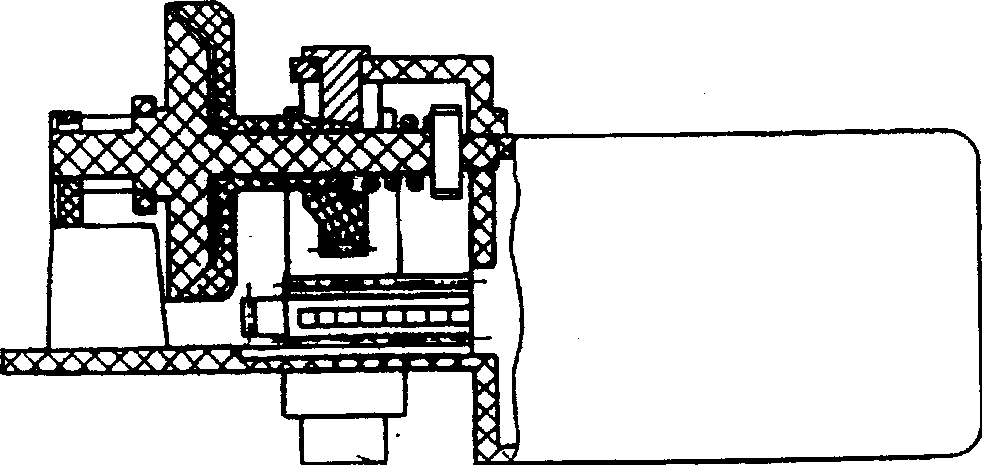

[0017] Embodiment 1. This automobile rearview mirror electric steering gear comprises motor 4, sphere cover 8, rotating sphere 7, is fixed with motor with motor pressure plate on the rotating sphere, and motor output shaft is connected with a first-level worm screw 3, a first-level The worm meshes with a first-stage worm gear 1, and the shaft center of the first-stage worm wheel is connected with a second-stage worm 2 through a semicircular shaft. The secondary worm gear 5 on the output shaft assembly, the secondary worm gear is positioned with the semi-circular shaft of the driving wheel, and is vacantly sleeved on the transmission shaft of the driven wheel assembly, and the end surface of the driving wheel is covered with a spring seat 12, which is connected with the nut 14 on the transmission shaft Between support has spring 13. The friction end surface of the driving wheel 11 has a concave cross-section with an inclined edge, which fits the friction end surface of the driv...

Embodiment 2

[0019] Embodiment 2. The friction slipping mechanism is on the driving wheel transmission shaft 15 of the fixed driving wheel, and is also connected with the worm wheel 5 in the fixed secondary worm gear reduction mechanism, and the axle sleeve is provided with a nut 14, between the nut and the sleeve frame 17 fixing the axle. A spring 13 is supported between them, and the driving wheel fits a driven wheel 10 friction end surface fixed on the driven wheel transmission shaft 16 through the friction end surface, and the shaft is also connected to the pinion of the fixed meshing rack, and others are as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com