Cycle beam for vibration suppression

A technology for suppressing vibration and straight beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of increasing difficulty and effect, vibration excitation powerlessness, etc., achieve good general vibration reduction effect, easy to implement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

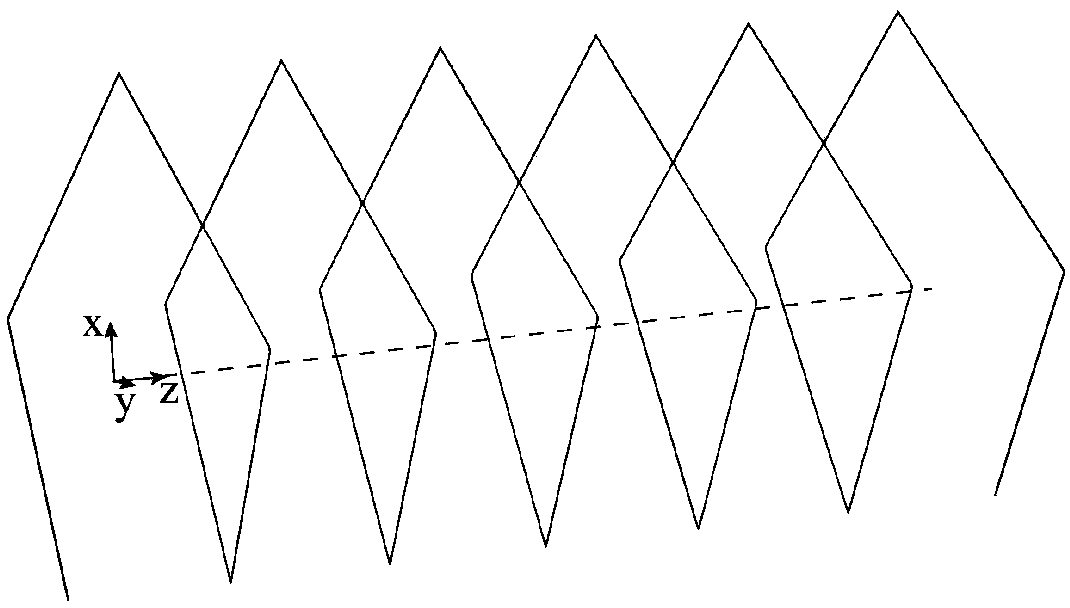

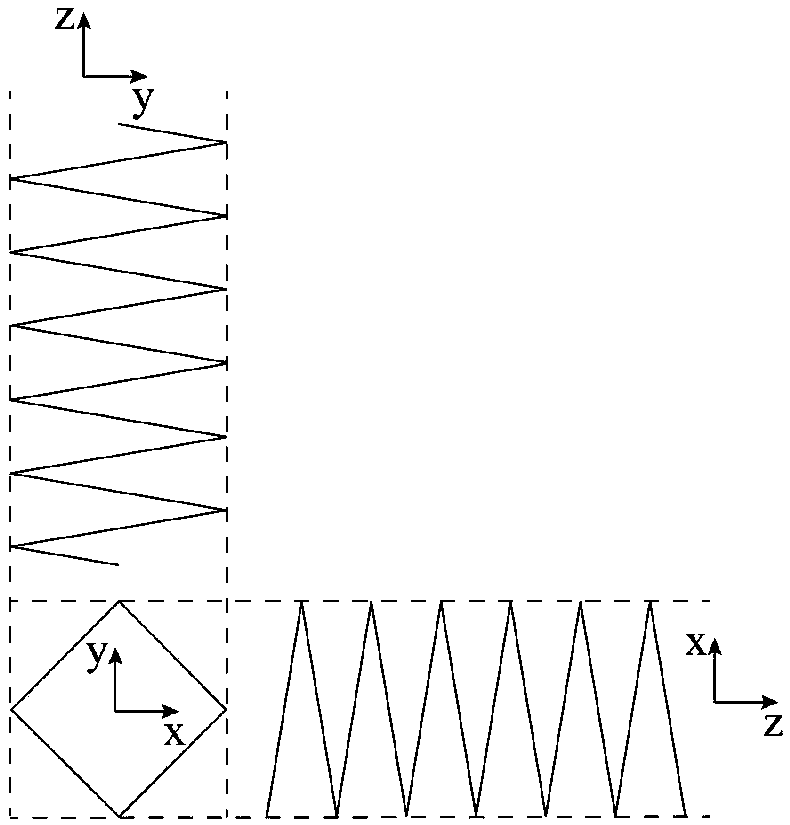

[0040] This embodiment discloses a periodic beam that suppresses vibration, such as figure 1 As shown, the periodic beam is in a spiral shape along a spatial axis, and is composed of 6 spatial four-fold line beam units connected, that is, the period number of the periodic beam is 6; the four-line beam unit is composed of four straight beams with the same length Three connection points are connected end to end to form an open space four-fold line beam, and the open space four-fold line beam is projected as a square on a certain plane.

[0041] Such as figure 2 As shown, the periodic beam takes a four-line beam unit as a period; as image 3 As shown, extending along the z-axis direction;

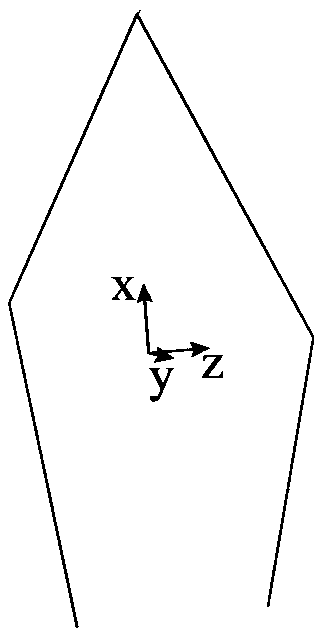

[0042] Such as Figure 4As shown, a four-fold line beam unit structure in this embodiment is projected as a square on a certain plane. The length of the diagonal of the square is the maximum length of the helical structure of the periodic beam in the direction perpendicular to the helical...

Embodiment 2

[0048] This embodiment discloses a vibration-suppressing periodic beam. Compared with Embodiment 1, the difference lies in that the periodic beam is composed of 15 spatial four-fold line beam units connected, that is, the periodic number of the periodic beam is 15.

[0049] A four-fold line beam unit structure in this embodiment is projected as a square on a certain plane. The length of the diagonal of the square is the maximum length of the helical structure of the periodic beam in the direction perpendicular to the helical axis, denoted as 2r; 0.0005m; 2r / a can be 100;

[0050] The beam section shape of the periodic beam is circular, and the circular diameter is 0.0001m;

[0051] The four-line beam unit is connected by straight beam bolts, and the periodic beam is welded by the four-line beam unit;

[0052] The four-fold line beam unit adopts a density of 1180kg·m -3 , the modulus of elasticity is 0.435×10 10 Pa, epoxy resin with Poisson's ratio of 0.368.

[0053] Takin...

Embodiment 3

[0055] This embodiment discloses a vibration-suppressing periodic beam. Compared with Embodiment 1, the difference lies in that the periodic beam is composed of 30 space four-fold line beam units connected, that is, the periodic number of the periodic beam is 30.

[0056] A four-fold line beam unit structure in this embodiment is projected as a square on a certain plane. The length of the diagonal of the square is the maximum length of the helical structure of the periodic beam in the direction perpendicular to the helical axis, denoted as 2r; 8m; 2r / a can be 0.001;

[0057] The beam section shape of the periodic beam is annular, the outer diameter of the annular is 0.05m, and the inner diameter is 0.01m;

[0058] The four-fold line beam unit is integrally formed, and the periodic beam is integrally formed;

[0059] The four-fold line beam unit adopts a density of 7800kg·m -3 , the modulus of elasticity is 21.0×10 10 Pa, steel with Poisson's ratio of 0.3.

[0060] Taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com