Special deicing vehicle for rails

A technology for deicing trucks and rails, which is applied to track cleaning, construction, cleaning methods, etc., and can solve problems such as low cleaning efficiency, easy freezing and snow accumulation on rails, and incomplete cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

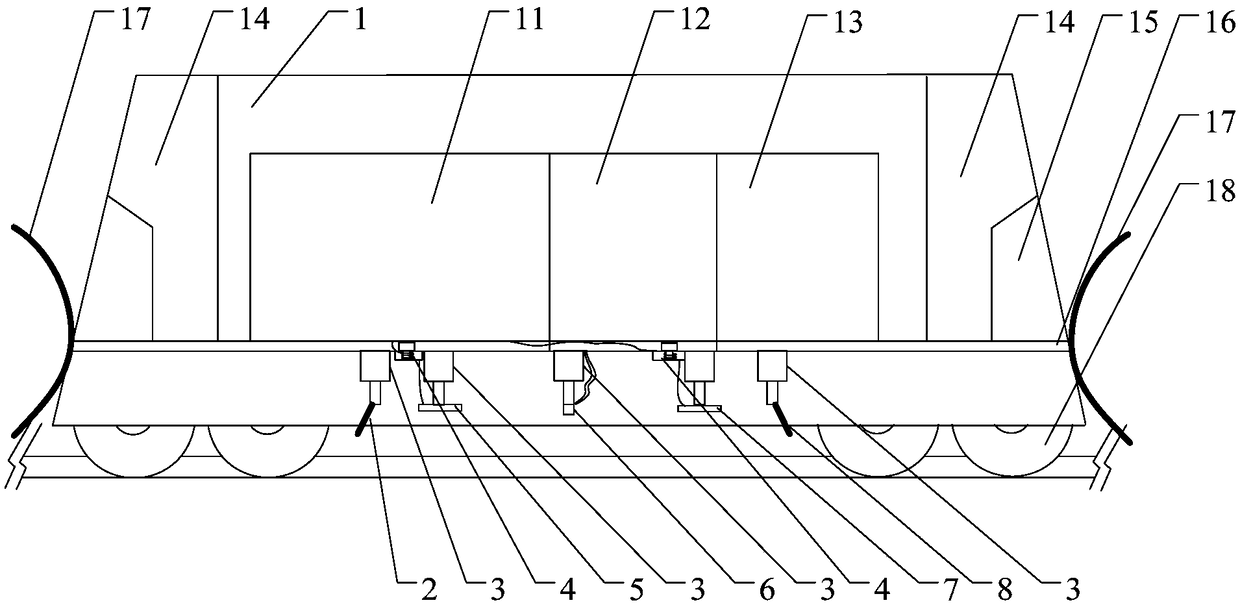

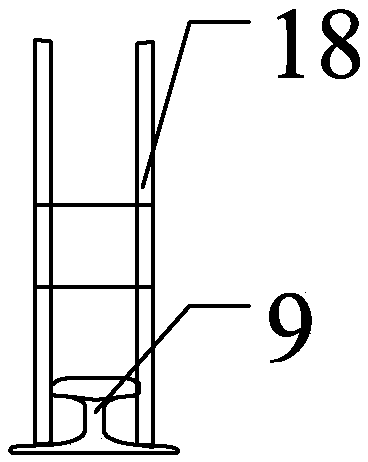

[0019] figure 1 It is a structural schematic diagram of a special deicing vehicle for rails in which the lifting device of the present invention is a plurality of telescopic cylinders, as figure 1 As shown, a rail-specific deicing vehicle includes a car body 1, and push buckets 17 are fixed at both ends of the car body 1, and when the snow accumulation is large, the upper layer of snow is pushed to both sides of the rail 9 by the push bucket 17. Both ends of the car body 1 are provided with a control room 14, and a console 15 is provided in the control room 14 for controlling the lifting and starting and stopping of the deicing mechanism. The inside of the car body 1 is provided with a power distribution room 13, a high-pressure air pump room 12, and an electromagnetic heating device room 11. A deicing mechanism is fixed below the chassis 16 of the car body 1. Two deicing mechanisms are arranged in parallel. The deicing mechanism and the rail 9 Relatively, a lifting device is...

Embodiment 2

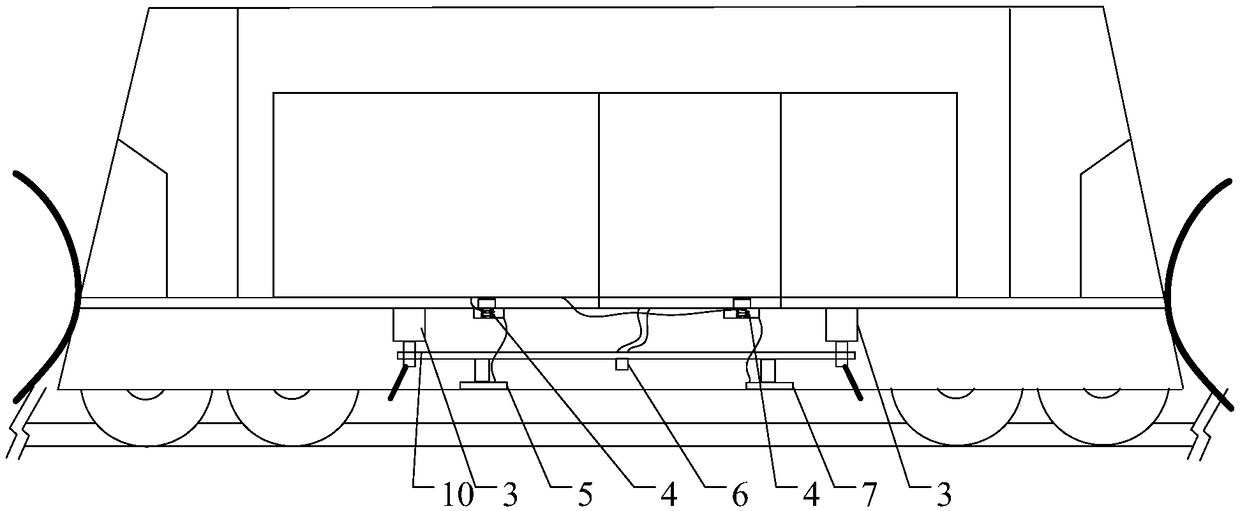

[0022] figure 2 It is a structural schematic diagram of a rail-specific deicing vehicle with a fixed plate in the lifting device of the present invention. The difference between this embodiment and Embodiment 1 is that the lifting device includes a fixed plate 10 and telescopic cylinders 3 arranged at both ends of the fixed plate 10. The first deicing The ice shovel 2, the first heating plate 5, the high-pressure nozzle 6, the second heating plate 7 and the second deicing shovel 8 are all fixed on the fixed plate, realizing the first deicing shovel 1, the first heating plate 5, the high pressure The blowing nozzle 6, the second heating plate 7 and the second deicing blade 8 are lifted and lowered simultaneously.

[0023] Therefore, the present invention adopts a special deicing vehicle for railroad tracks with the above-mentioned structure, and the deicing is cleaner, and the principle of electromagnetic induction is used to make the rails self-heating, so that the ice and sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com