Water-based paint filtering device with self-cleaning function

A water-based paint and filter device technology, which is applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of inability to meet batch processing, filter screen cleaning that cannot be installed, poor filtration speed, etc., to prevent The effect of blocking holes in the filter screen, reducing labor and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

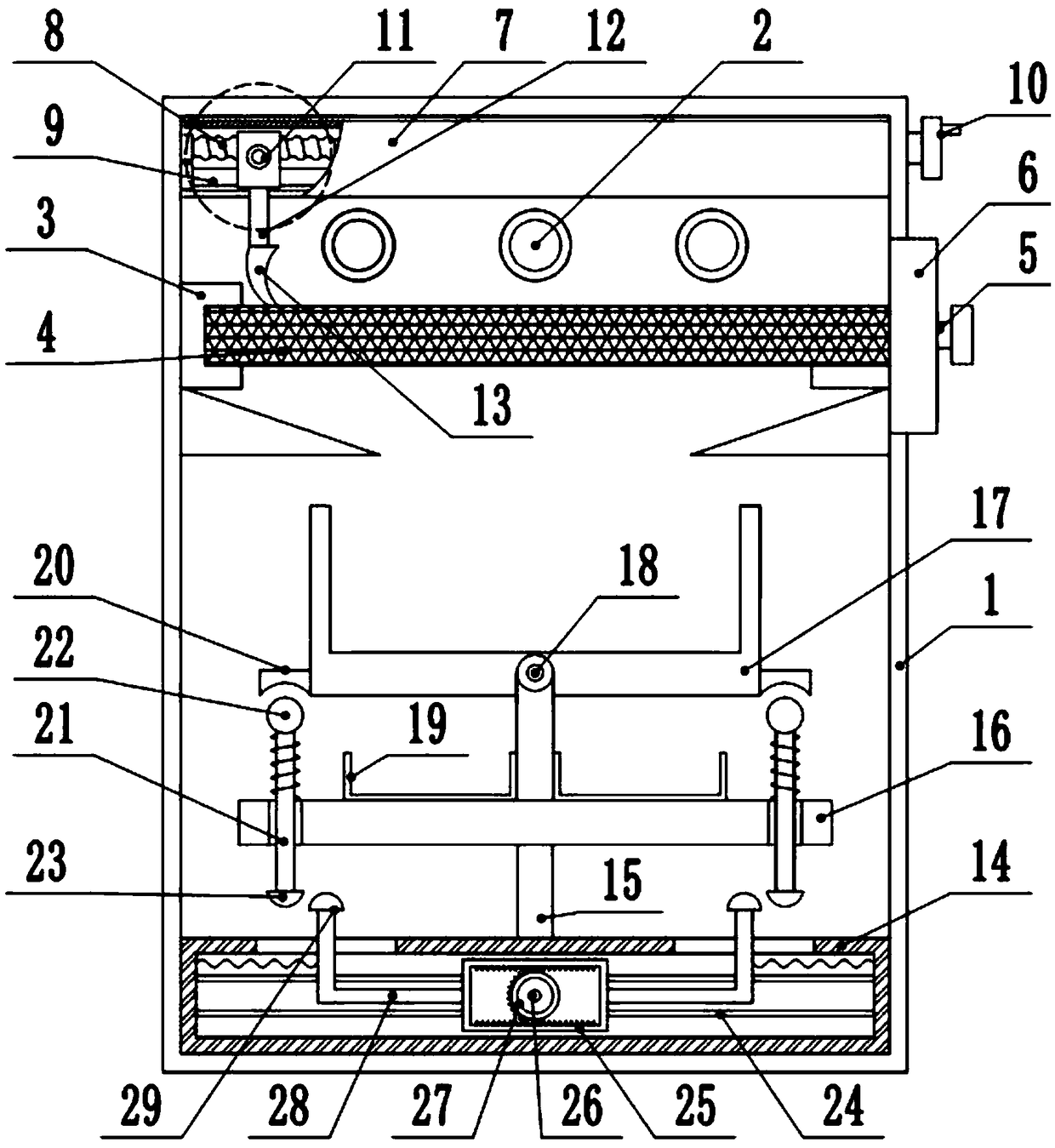

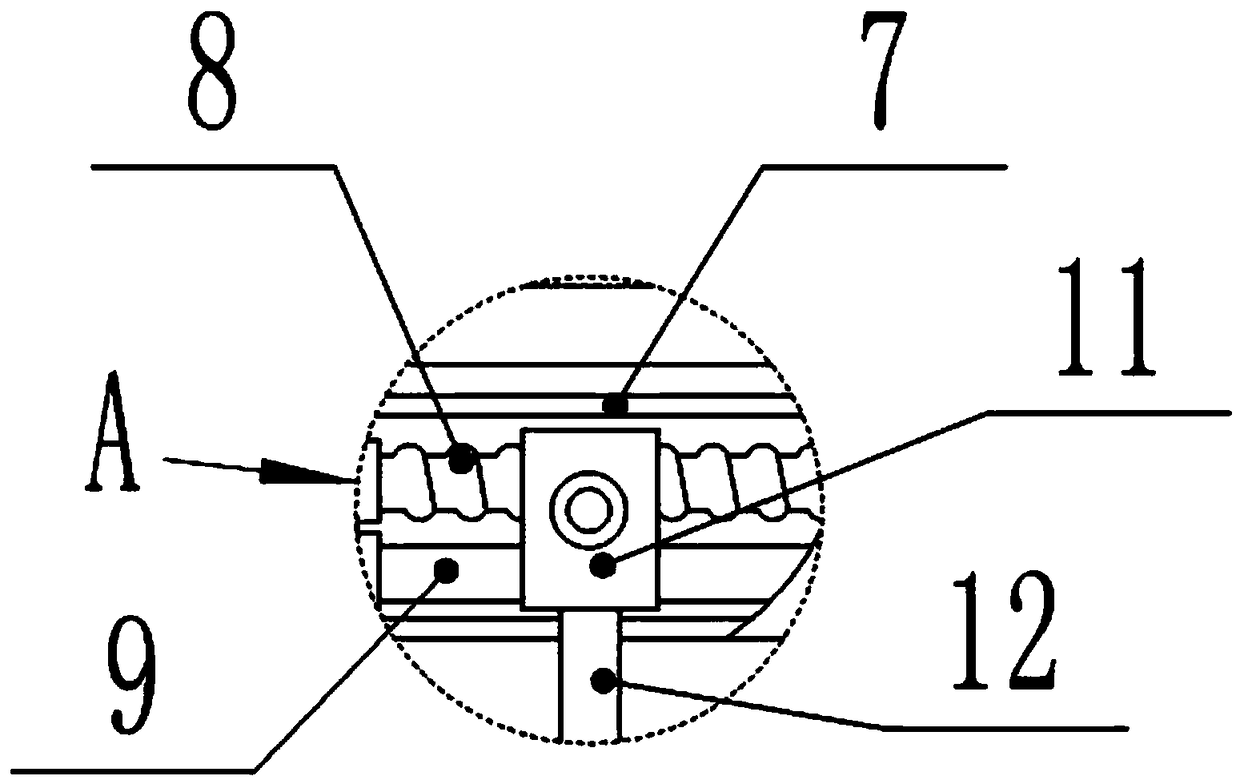

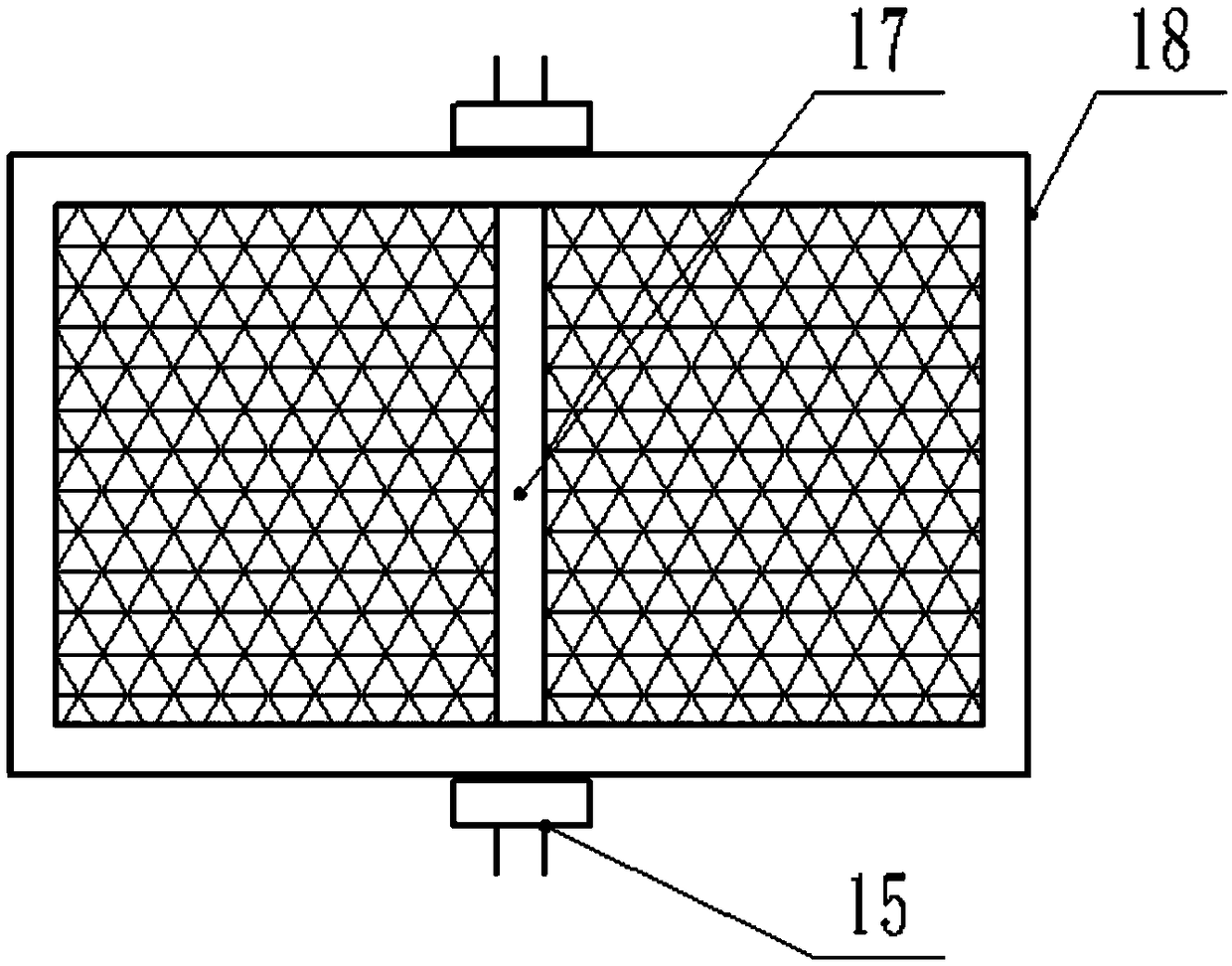

[0021] see Figure 1-3 , a water-based paint filter device with self-cleaning function, comprising a paint filter box 1, a filter plate 4 impurity scrapers 13 and a swing filter box 17, the rear side of the paint filter box 1 is provided with several groups of sewage outlets 2, the sewage filter The other end of the port 2 is connected to the external sewage storage device through the liquid inlet pipe, and the water-based paint to be treated is added to the inside of the paint filter box 1 through the sewage outlet 2. The inside of the paint filter box 1 is provided with a filter plate slot 3, and the filter plate A filter plate 4 is mounted on the card slot 3, and there are several groups of filter holes on the filter plate 4. The filter holes are circular holes and the diameter of the circular hole is 5-6 mm. Through the preliminary filtering ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com