Motor protecting method of food processing machine

A food processing machine, motor protection technology, applied in household appliances, applications, kitchen utensils, etc., can solve the problem that the motor cannot be effectively protected, and achieve the effect of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

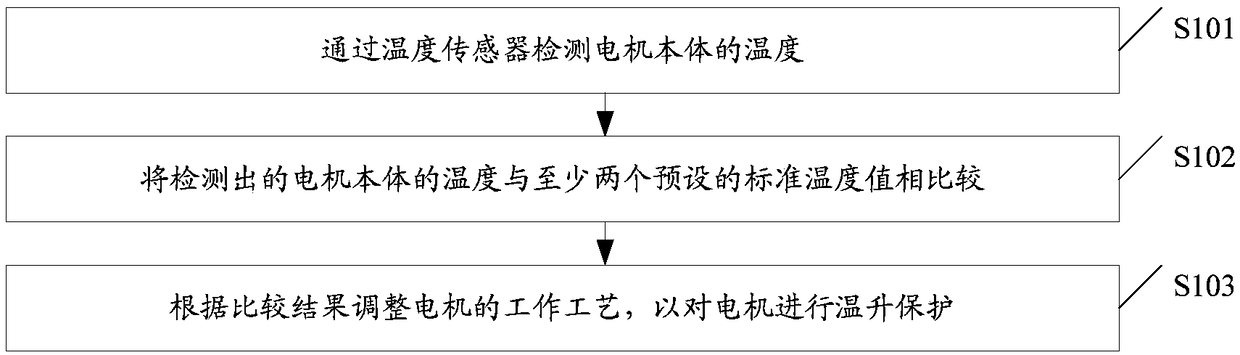

[0056] An embodiment of the present invention provides a motor protection method for a food processing machine. The food processing machine may include a temperature sensor and a motor, such as figure 1 As shown, the method may include S101-S103:

[0057] S101. Detect the temperature of the motor body through a temperature sensor;

[0058] S102. Comparing the detected temperature of the motor body with at least two preset standard temperature values;

[0059] S103. Adjust the working process of the motor according to the comparison result, so as to protect the motor from temperature rise.

[0060] In the embodiment of the present invention, the food processing machine can be composed of an operation interface, a control circuit board, a heating module, a crushing chamber, and a motor, wherein the control circuit board can be provided with a main control circuit or a main control chip; A temperature sensor is provided, and the temperature sensor can provide the detected tempe...

Embodiment 2

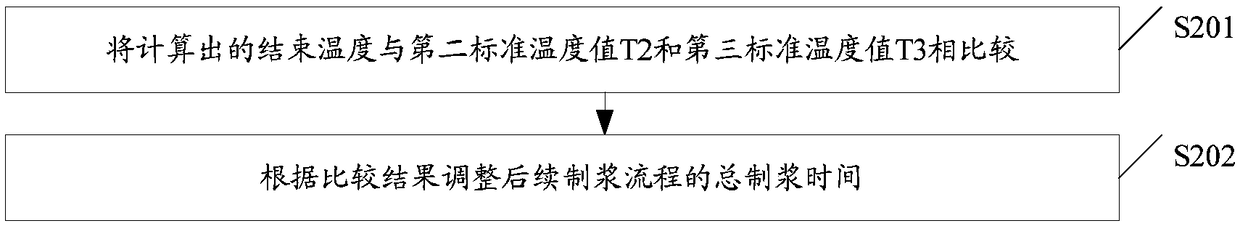

[0065] This embodiment provides several specific examples of standard temperature values on the basis of the first embodiment.

[0066] Optionally, the preset standard temperature values may include: a first standard temperature value T1, a second standard temperature value T2 and a third standard temperature value T3;

[0067] Wherein, the first standard temperature value T1 is less than the second standard temperature value T2, the second standard temperature value T2 is less than the third standard temperature value T3, and the third standard temperature value T3 is less than or equal to the insulation failure temperature value of the motor body.

[0068] In the embodiment of the present invention, the solution of this embodiment realizes three-level temperature protection for the motor, so as to limit the temperature of the motor body from exceeding the standard and ensure that the motor is not damaged.

[0069] In the embodiment of the present invention, the third sta...

Embodiment 3

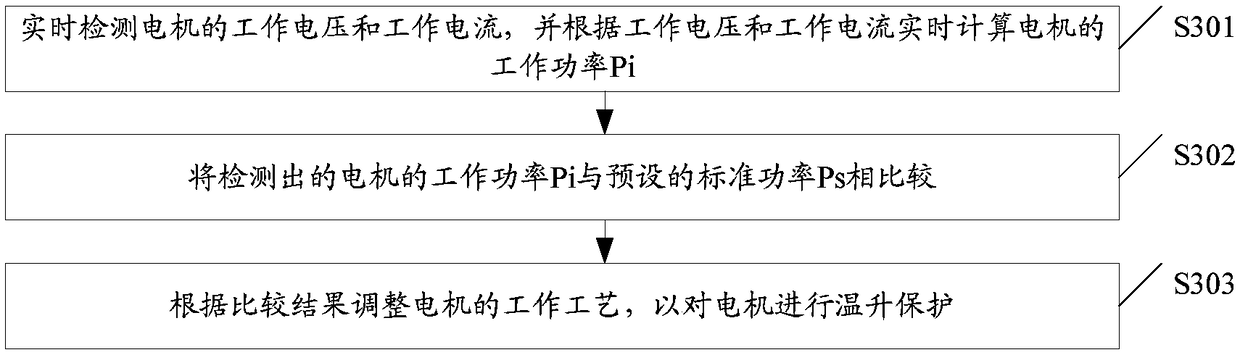

[0071] On the basis of the second embodiment, this embodiment provides a specific implementation manner of adjusting the working process of the motor according to the comparison result.

[0072] Optionally, adjusting the working process of the motor according to the comparison result may include the following situations 1-4:

[0073] 1. When the detected temperature of the motor body is less than or equal to the first standard temperature value T1, control the motor to run according to the preset working process.

[0074] In the embodiment of the present invention, during the operation of the motor, when it is detected that the temperature of the motor body is lower than the first standard temperature value T1, it means that the current temperature of the motor body is kept within an absolutely safe temperature range, so the original set speed can be used. run.

[0075] 2. When the detected temperature of the motor body is greater than the first standard temperature value T1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com