Method for producing fermented tea

A production method and technology of fermented tea, applied in tea substitutes, bacteria used in food preparation, food science, etc., can solve problems such as unstable quality, turbid soup color, and low tea fragrance, so as to improve immunity and mellow taste , Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

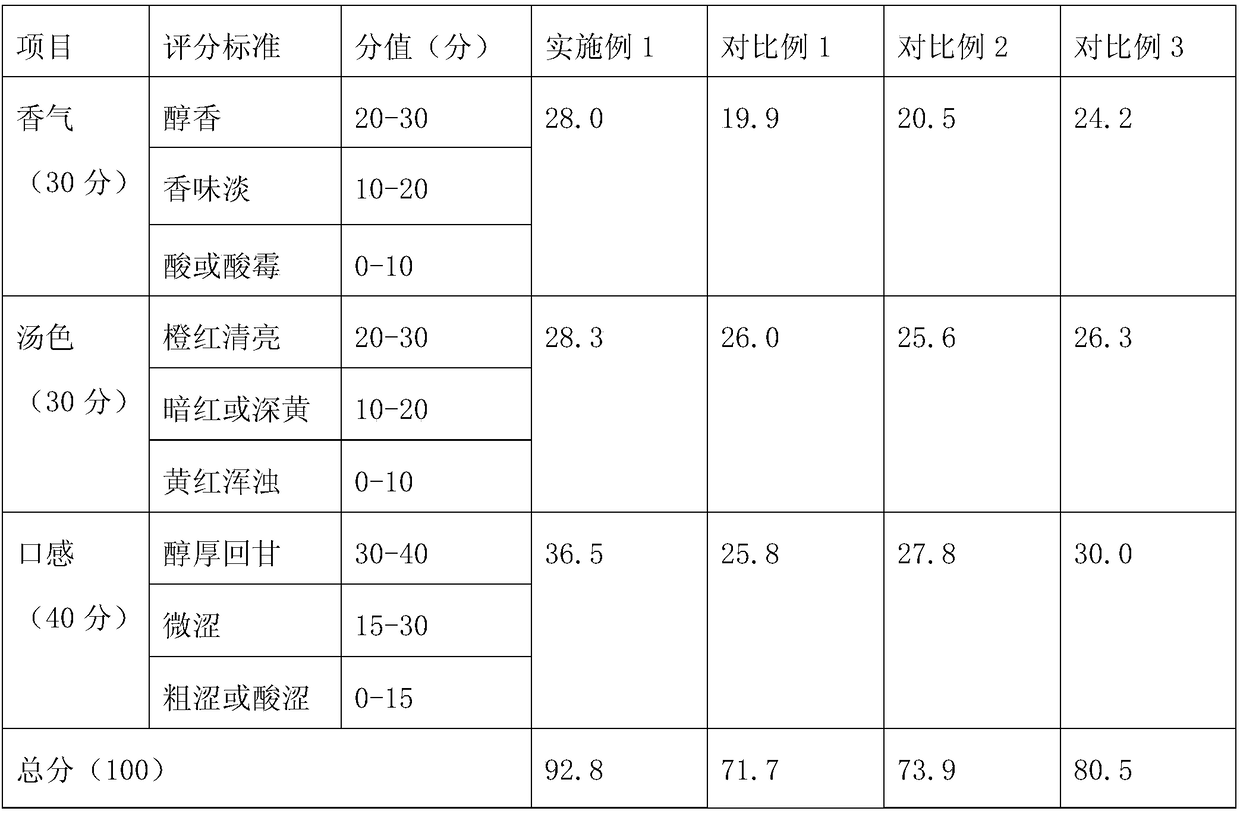

Examples

Embodiment 1

[0026] A production method of fermented tea, comprising the steps of:

[0027] (1) Pick fresh tea leaves, put them into an automatic stir-frying machine to stir-fry and dry, the stir-frying temperature is 70°C, add bran when stir-frying, the mass ratio of the tea leaves and bran is 1:0.9, stir-fry When the dehydration rate of the tea leaves is 80-85%, the tea leaves are taken out and pulverized to obtain tea powder; the tea leaves are Gynostemma pentaphyllum.

[0028] (2) Add sliced tomatoes, passion fruit juice, and rock sugar into clear water, the mass ratio of the clear water, tomatoes, passion fruit juice, and rock sugar is 580:45:26:22, mix evenly, and seal After standing for 4 days, filter the filtrate, add tea powder to the filtrate, the weight ratio of the tea powder to the filtrate is 1:22, soak for 40 minutes to obtain a tea mixture;

[0029] (3) Insert strains into the tea mixture for fermentation, the total amount of the strains is 0.05% of the weight of the tea...

Embodiment 2

[0033] A production method of fermented tea, comprising the steps of:

[0034] (1) Pick fresh tea leaves, put them into an automatic stir-frying machine to stir-fry and dry, the stir-frying temperature is 68°C, add bran when stir-frying, the mass ratio of the tea leaves and bran is 1:0.8, stir-fry When the dehydration rate of the tea leaves is 80-85%, the tea leaves are taken out and pulverized to obtain tea powder; the tea leaves are Gynostemma pentaphyllum.

[0035] (2) Add sliced tomatoes, passion fruit juice, and rock sugar into clear water, the mass ratio of the clear water, tomatoes, passion fruit juice, and rock sugar is 530:35:22:15, mix evenly, and seal After standing for 3 days, filter the filtrate, add tea powder to the filtrate, the weight ratio of the tea powder to the filtrate is 1:20, soak for 35 minutes to obtain a tea mixture;

[0036] (3) adding strains to the tea mixture for fermentation, the total amount of the strains is 0.04% of the weight of the tea m...

Embodiment 3

[0040] A production method of fermented tea, comprising the steps of:

[0041] (1) Pick fresh tea leaves, put them into an automatic stir-frying machine for frying and drying, the stir-frying temperature is 72°C, add bran when stir-frying, the mass ratio of the tea leaves and bran is 1:1, stir-fry When the dehydration rate of the tea leaves is 80-85%, the tea leaves are taken out and pulverized to obtain tea powder; the tea leaves are Gynostemma pentaphyllum.

[0042] (2) Add sliced tomatoes, passion fruit juice, and rock sugar into clear water, the mass ratio of the clear water, tomatoes, passion fruit juice, and rock sugar is 570:45:27:25, mix evenly, and seal After standing for 5 days, filter the filtrate, add tea powder to the filtrate, the weight ratio of the tea powder to the filtrate is 1:25, soak for 45 minutes to obtain a tea mixture;

[0043] (3) adding strains to the tea mixture for fermentation, the total amount of the strains is 0.06% of the weight of the tea m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com