Invisible anti-collision linear motor

A linear motor, invisible technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as impact on other components, equipment damage, safety hazards, etc., to slow down the impact, reduce the external space occupied, and increase the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

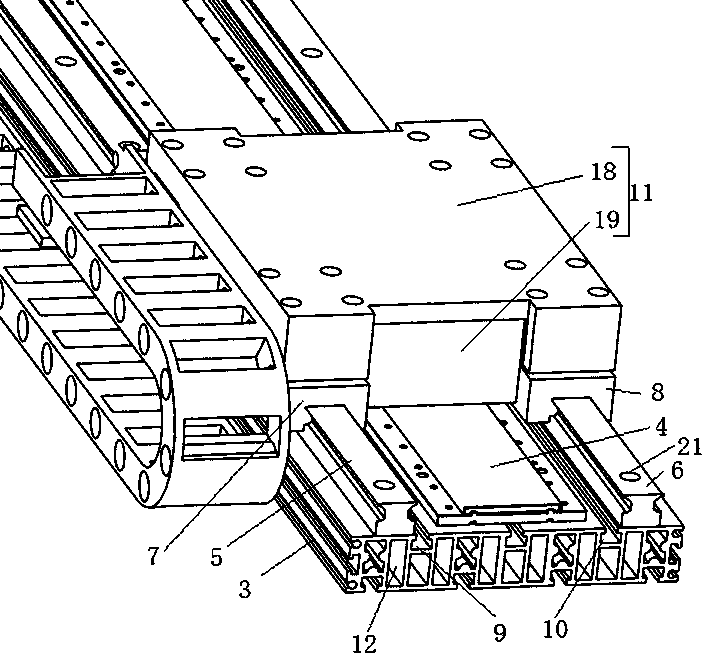

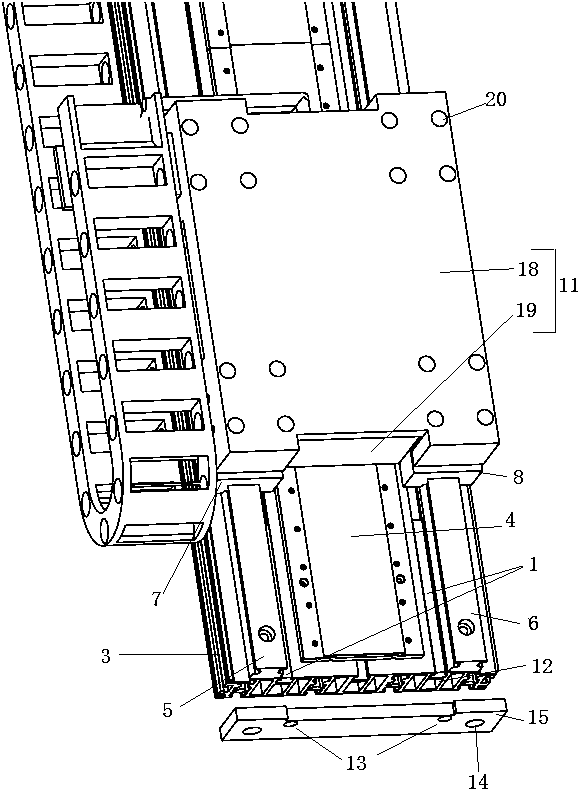

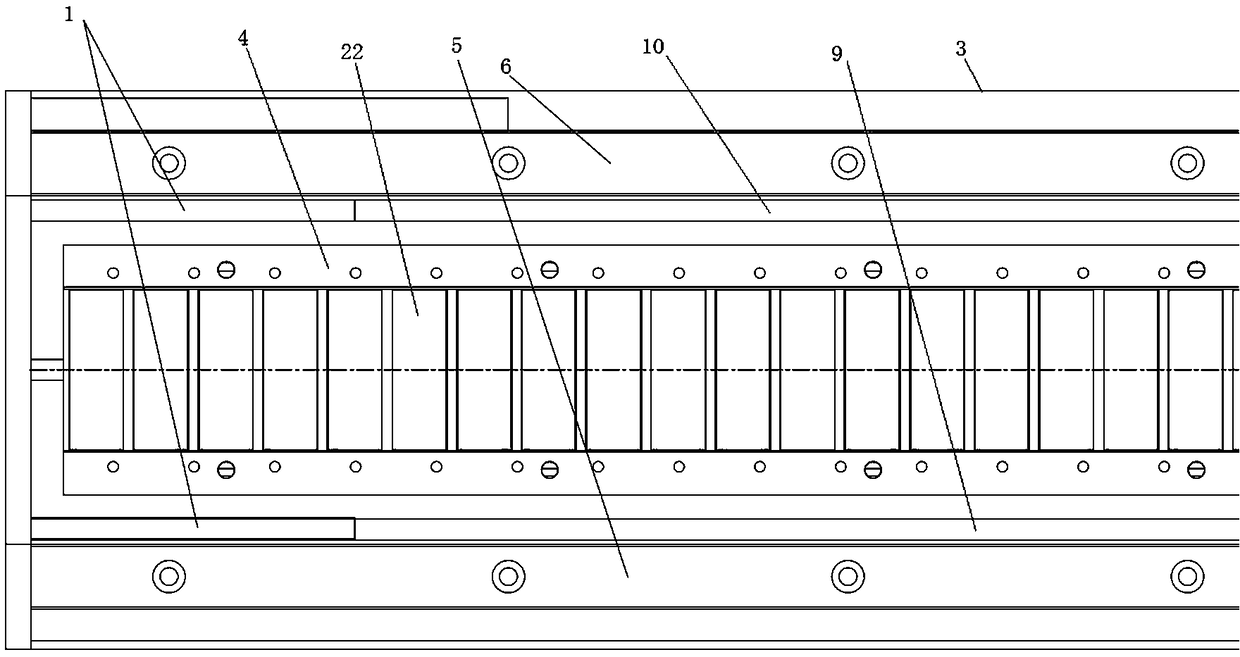

[0021] The following is based on Figure 1 to Figure 6 The specific embodiment of the present invention is further described:

[0022] see figure 1 and figure 2 , an invisible anti-collision linear motor, including a primary component 11 and a secondary component 4, and also includes a substrate 3, a first slider 7, a second slider 8, a first guide rail 5, a second guide rail 6, an invisible mechanical anti-collision device 1 and end plate 15, the secondary component 4 is installed in the middle of the upper surface of the base plate 3, and the upper surface of the base plate 3 is installed with a first guide rail 5 and a second guide rail 6 extending along its length direction ( figure 1 In the upper surface of the first guide rail 5 and the second guide rail 6, it can be seen that there is a hole 21, which is a screw fixing hole for fixing on the substrate 3), the first guide rail 5 and the second guide rail The guide rails 6 are respectively located on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com