Test system for simulating deformation and failure characteristics of tunnel

A technology for testing systems and destructive characteristics, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as deviation of experimental results, temporary solutions, and unreasonable treatment plans, so as to achieve uniform distribution and accurate simulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

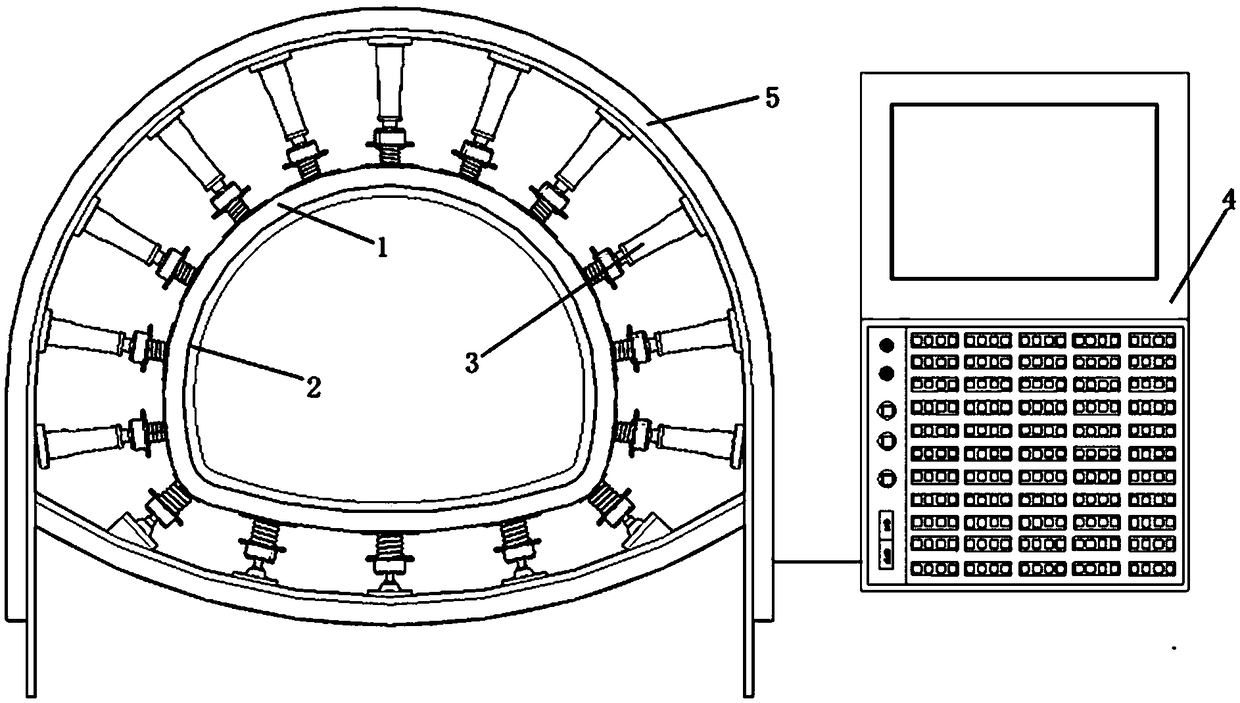

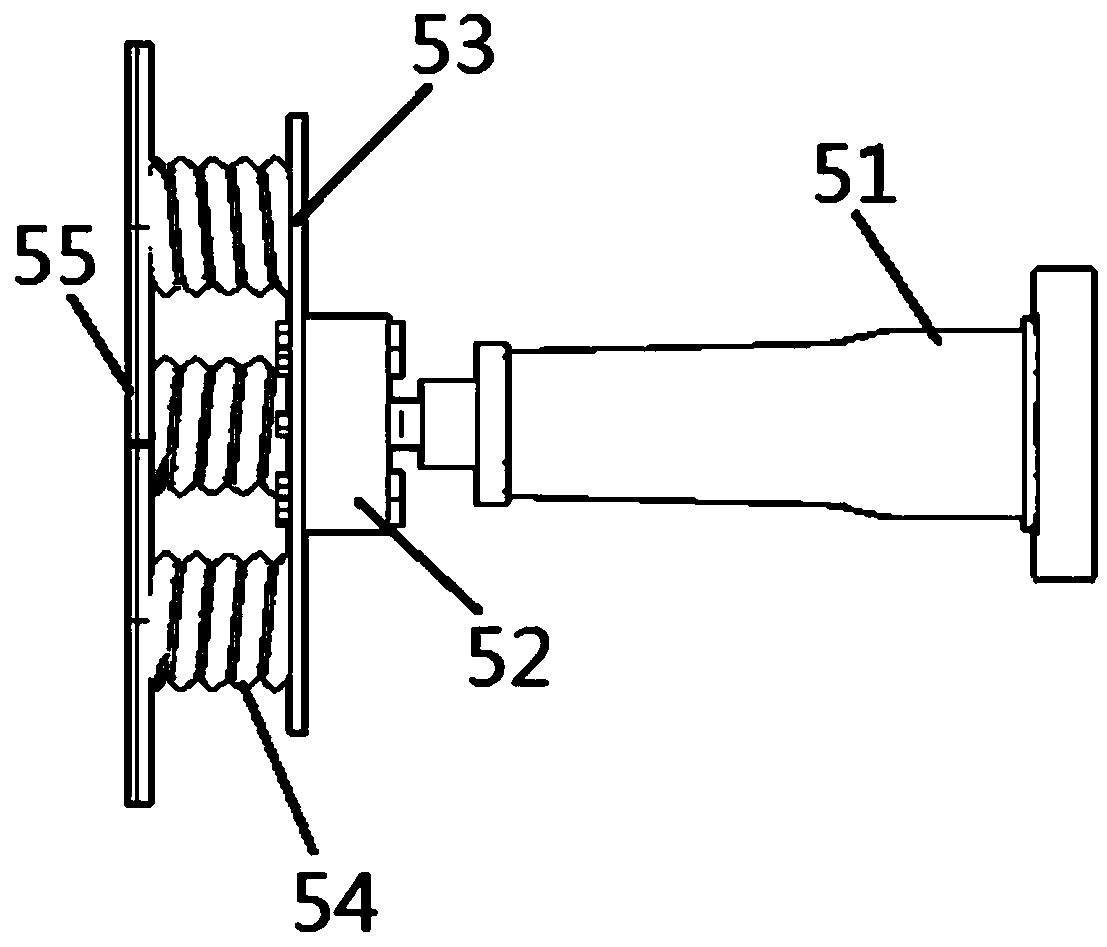

[0041] This embodiment provides a test system for simulating the deformation and failure characteristics of tunnels. In this test system, the tunnel second lining model 1 is placed on the auxiliary support subsystem, and external loads are arranged along the entire outer surface of the tunnel second lining model 1. The resistance subsystem 3, the two sides of the external load resistance subsystem 3 are respectively connected with the second lining model 1 of the tunnel and the reaction subsystem 5, and connected with the servo controller 4 on the industrial computer together with the measurement subsystem to realize the external load of the structure. Collect and analyze unloading and measurement data, and study structural deformation and crack damage under load, as well as maintenance effects under different timing and reinforcement methods.

[0042] Among them, the second lining model 1 of the tunnel corresponds to the tunnel prototype with two to four lanes in a single hole...

Embodiment 2

[0065] The structure of the test system in this example is exactly the same as that in Example 1, but this example is a test system for studying the deformation and failure characteristics of the second lining structure of the tunnel under the action of bias load. Therefore, in this example, the active load is applied The area is different from Example 1, specifically as Figure 5 shown.

Embodiment 3

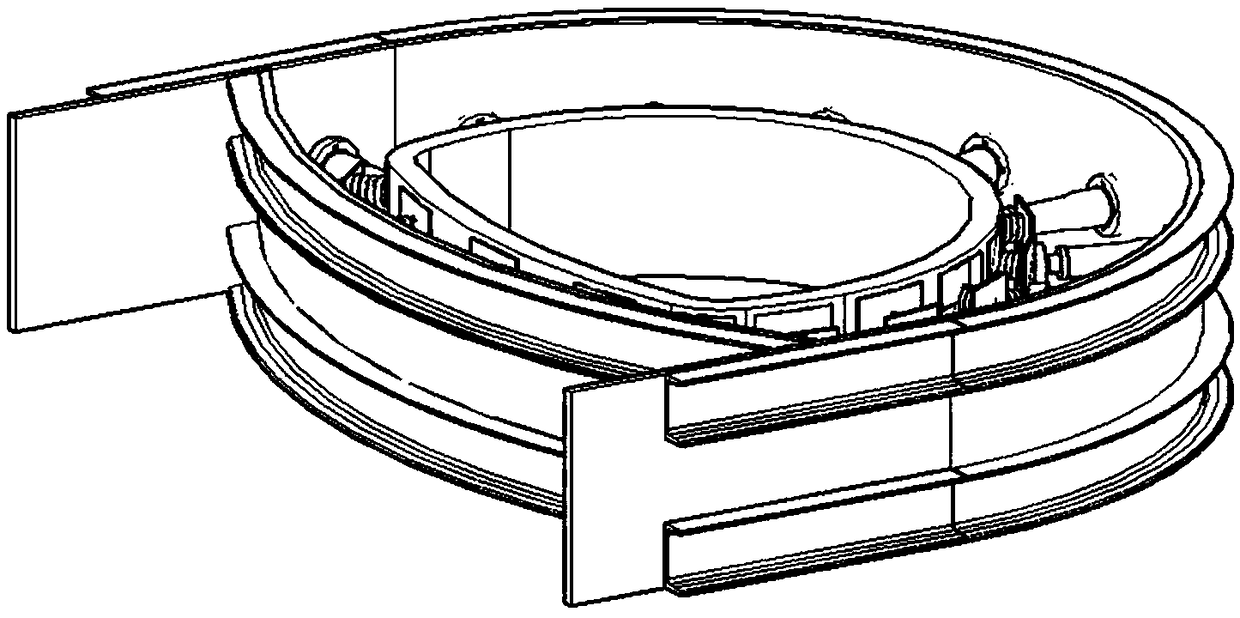

[0067] The test system in this embodiment adds a reinforcement sub-module 2. The reinforcement sub-module 2 includes three types of arches, bonded steel, and fiber. It is made by cast-in-place or pasted. During the manufacturing process, the external load of the second lining model 1 of the tunnel is maintained. Basically unchanged, the cast-in-place method simulates the reinforcement of superimposed arches or separated arches, and the pasting method simulates pasting steel plates or pasting fibers, and a connection and separation mechanism is added between the reinforcement sub-module 2 and the second tunnel lining model 1 , the connection and separation mechanism includes short anchor rods, waterproof boards, layering strips, and pins. If a superimposed arch is used for reinforcement, the inner surface of the second lining model 1 of the tunnel should be chiseled, and short anchors with a diameter of 3 to 4 mm should be used at a certain interval along the circumferential dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com