Powder combustion and eruption device simulating effect of cold light fireworks

A technology of powder and pyrotechnics, which is applied in the field of powder combustion eruption devices, can solve the problems of large size, high equipment cost, complex structure, etc., and achieve the effect of rich expression means and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

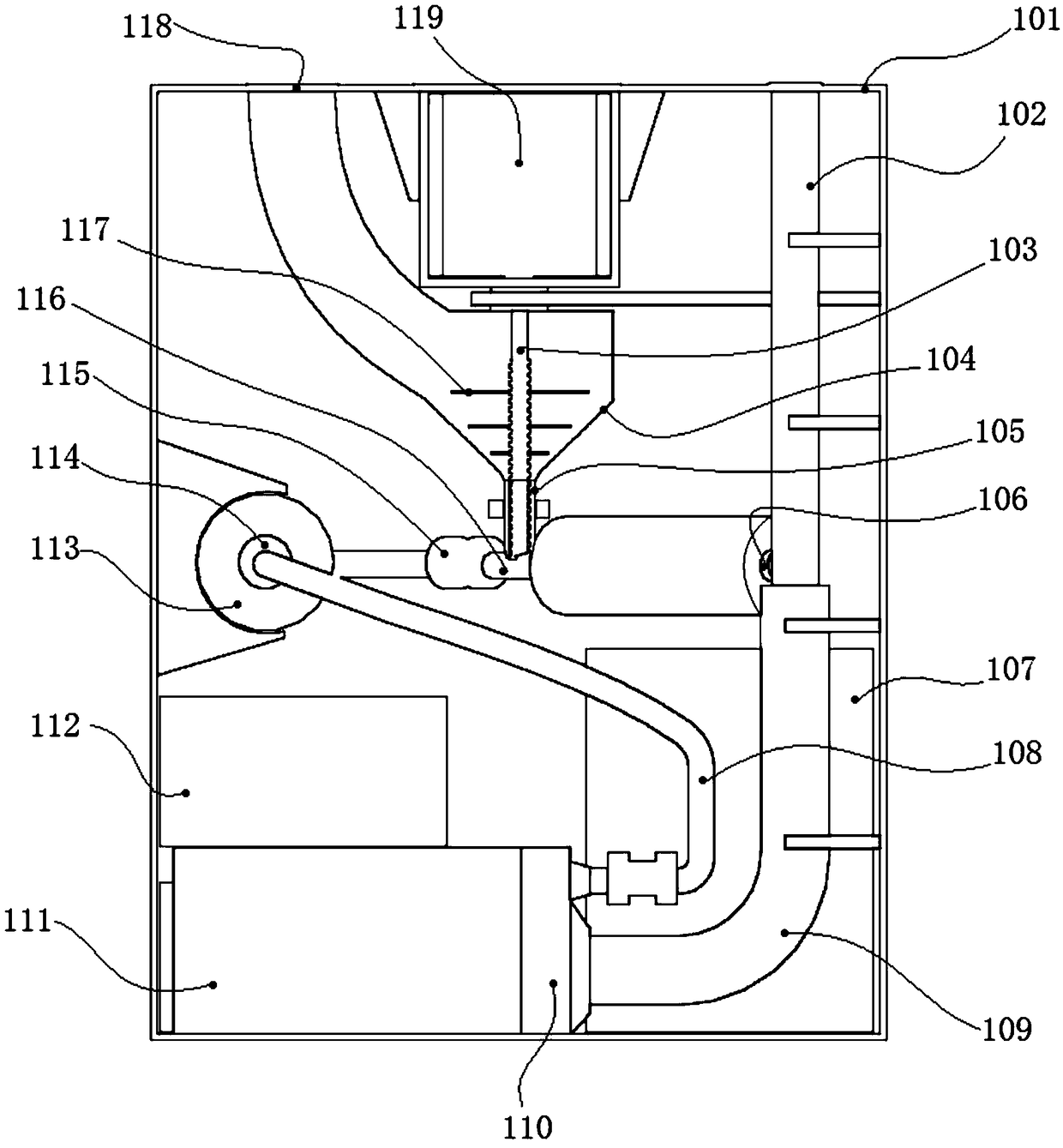

[0019] Embodiment 1: see attached figure 1 , reflecting a specific structure of the present invention, the powder combustion eruption device for imitating luminescent firework effects includes a casing 101, a power supply 107, a wireless control module 112, etc., and also includes a lower hopper 104 for loading powder through a filling port 118, the lower The hopper 104 is provided with a tubular feeding port 105, and the inner cavity of the tubular feeding port 105 is provided with a screw feeding rod 103, and the screw feeding rod 103 is connected with a speed regulating motor 119 as a rotation driving mechanism. The feeding rate of the screw conveying rod 103 can be controlled by controlling the speed and working time of the speed-regulating motor, so as to realize uniform metering and feeding. The screw feeding rod 103 is provided with three sets of agitating elements 117 whose radial dimensions gradually decrease on the rod body outside the tubular feeding opening 105 . ...

Embodiment 2

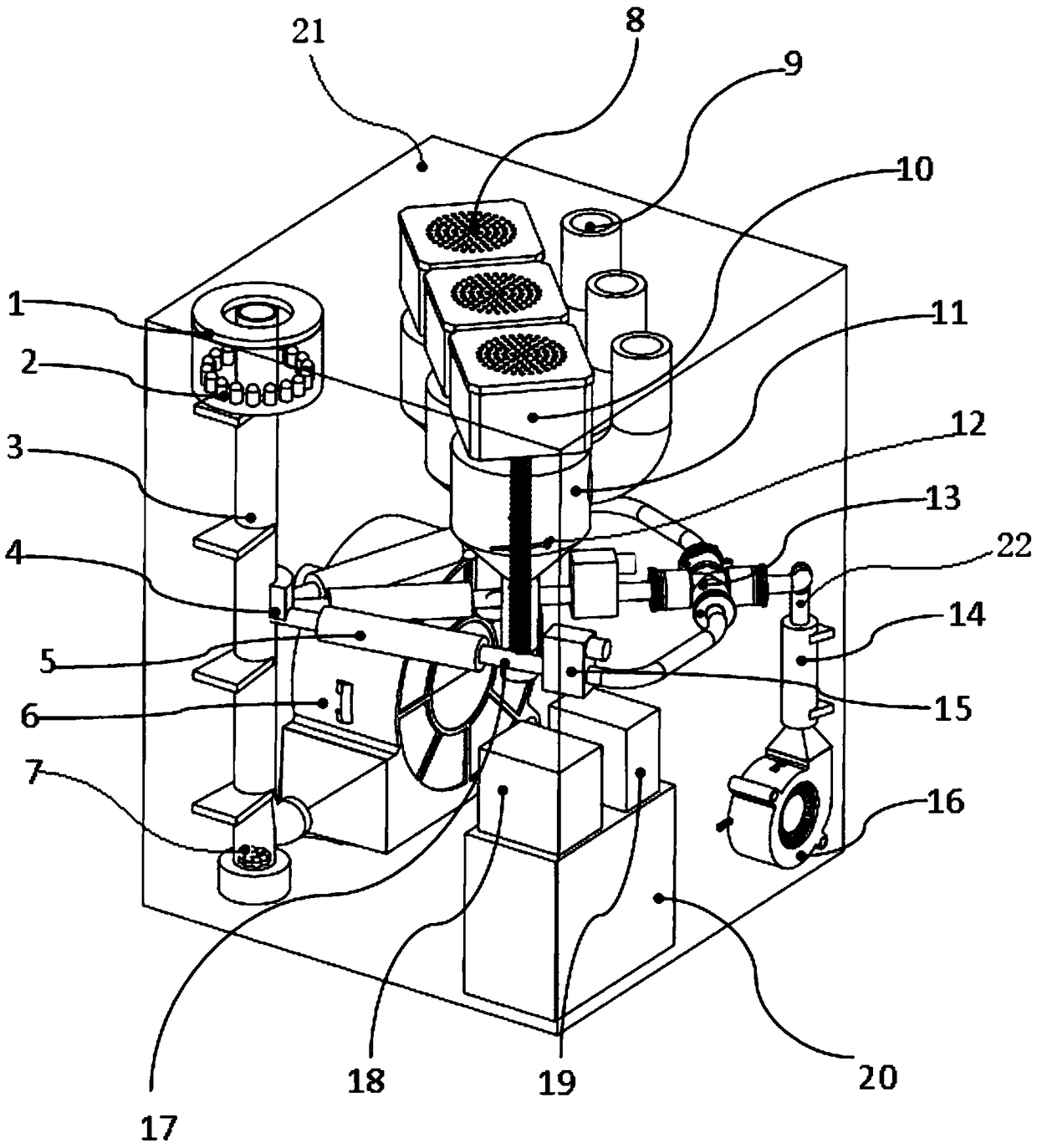

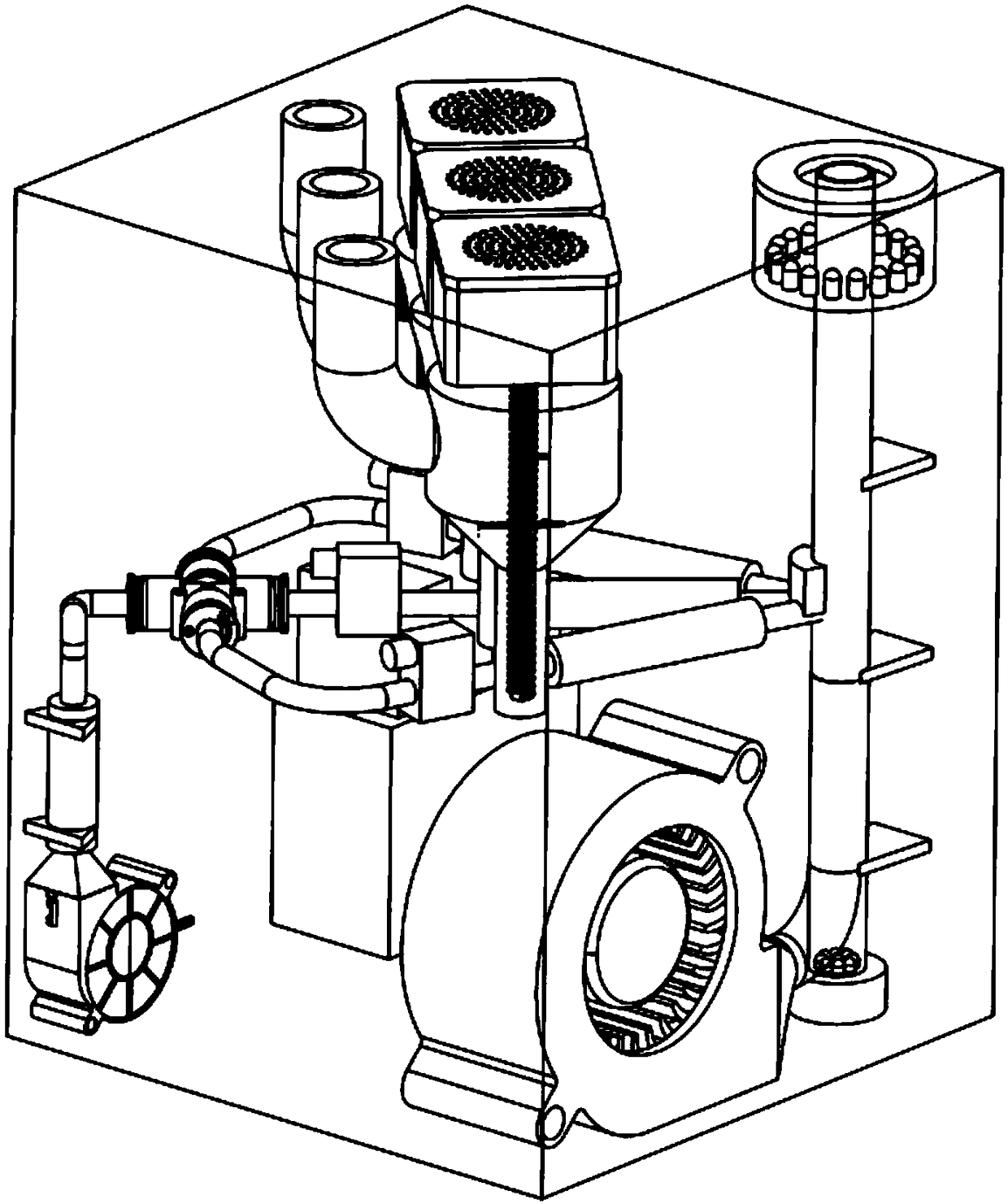

[0024] Embodiment 2: see attached figure 2 , 3 , including a multifunctional wiring device 18 , a wireless control module 19 and a power supply 20 installed in the housing 21 . In order to realize the eruption of multiple light colors, three lower hoppers 11 arranged side by side are included in this example, and each lower hopper 11 is loaded with powders of different flame colors through the filling port 9 . A screw feeding rod driven by a motor 10 and an agitator 12 are installed in the lower hopper 11 , and the motor 10 is provided with a cooling port 8 facing outside the casing 21 .

[0025] The bottom of each lower hopper 11 is correspondingly provided with a powder-gas mixing chamber 17 and its insulation layer 5, and the A ends of each powder-gas mixing chamber 17 are respectively connected to the four-way tap 13 of the intake pipe 22 through the electromagnetic valve 15, and the intake pipe 22 is provided with Insulation layer 14, special feeding fan 16 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com