Anchorage hole integrated drilling and reaming construction method

A construction method and an integrated technology, applied in drilling equipment and methods, drilling with liquid/gas jets, drilling equipment, etc. Rod slippage instability and other problems to achieve the effect of ensuring safety, light weight, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

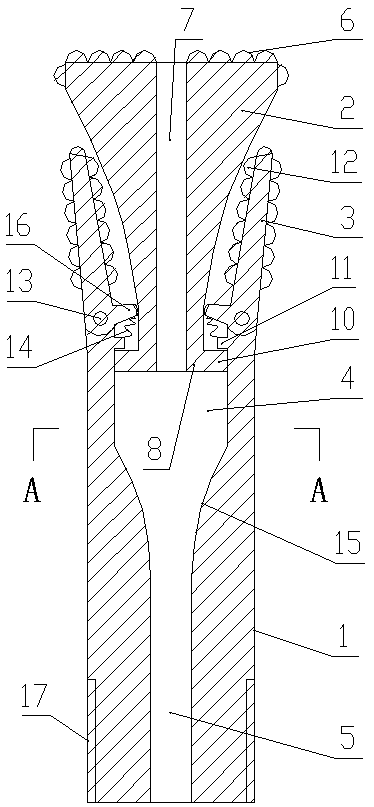

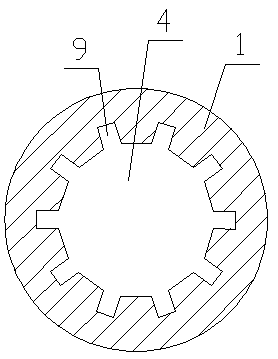

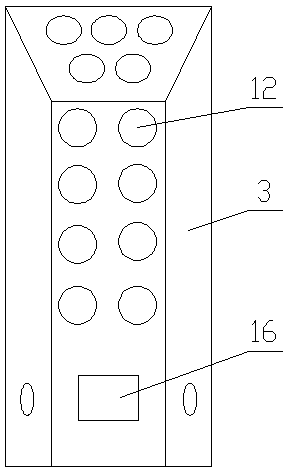

[0025] Such as Figure 1-Figure 6 As shown, the anchor hole integrated drilling and reaming construction method of the present invention comprises the following steps:

[0026] (1) Determine the position of drilling anchor holes in the area to be supported planned in the roadway;

[0027] (2) Assemble or connect the drilling rig, drill pipe, high-pressure water pipe and integrated drilling and reaming device; the drilling rig, drill pipe, and high-pressure water pipe are not shown in the figure;

[0028] (3) Manipulate the integrated drilling and reaming device to drill the determined anchor hole position, stop drilling after the drill hole reaches the set depth, and ream the bottom of the anchor hole;

[0029] (4) After the reaming is completed, withdraw the integrated drilling and reaming device from the anchor hole to complete the drilling and reaming operations.

[0030] The integrated drilling and reaming device includes a drilling and reaming rod 1, a drilling tool 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com