Floor drain connecting device and construction method thereof

A connecting device and floor drain technology, which is applied to water supply devices, building components, drainage structures, etc., can solve problems such as the influence of anti-leakage work, the long time span of floor drain installation, and the large investment in inspection and acceptance manpower, so as to reduce the inspection and acceptance manpower, The effect of long installation time span and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The installation of the floor drain in the prior art includes the following steps:

[0043] (1) Positioning: After hoisting the template, mark the installation position of the floor drain on the template and check whether the positioning is accurate;

[0044] (2) Reserved holes: mark the position of the floor drain on the formwork, fix the pre-embedded hole-forming mold on the formwork with nails, and bind the steel frame of the floor at the same time. Pour them together to form a reinforced concrete floor slab 7, and check the reserved holes;

[0045] (3) Clean up the reserved holes: after the reinforced concrete floor slab 7 is formed, take off the pre-embedded hole-forming mold, clean up the chiseled hairs of the reserved holes, and check the cleaning situation of the reserved holes;

[0046] (4) Install the floor drain connection pipe: After verifying the floor drain elevation, install the floor drain connection pipe at the reserved hole, and check the floor drain ...

Embodiment 2

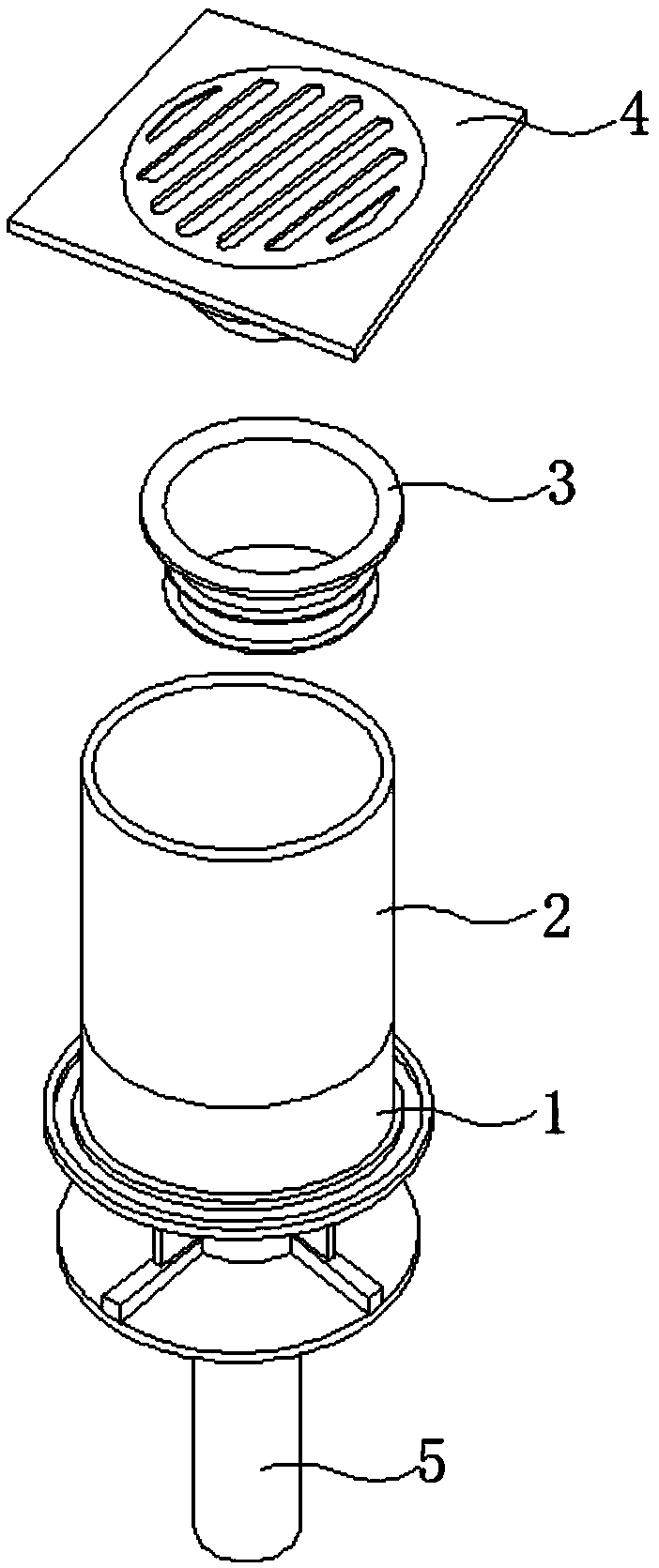

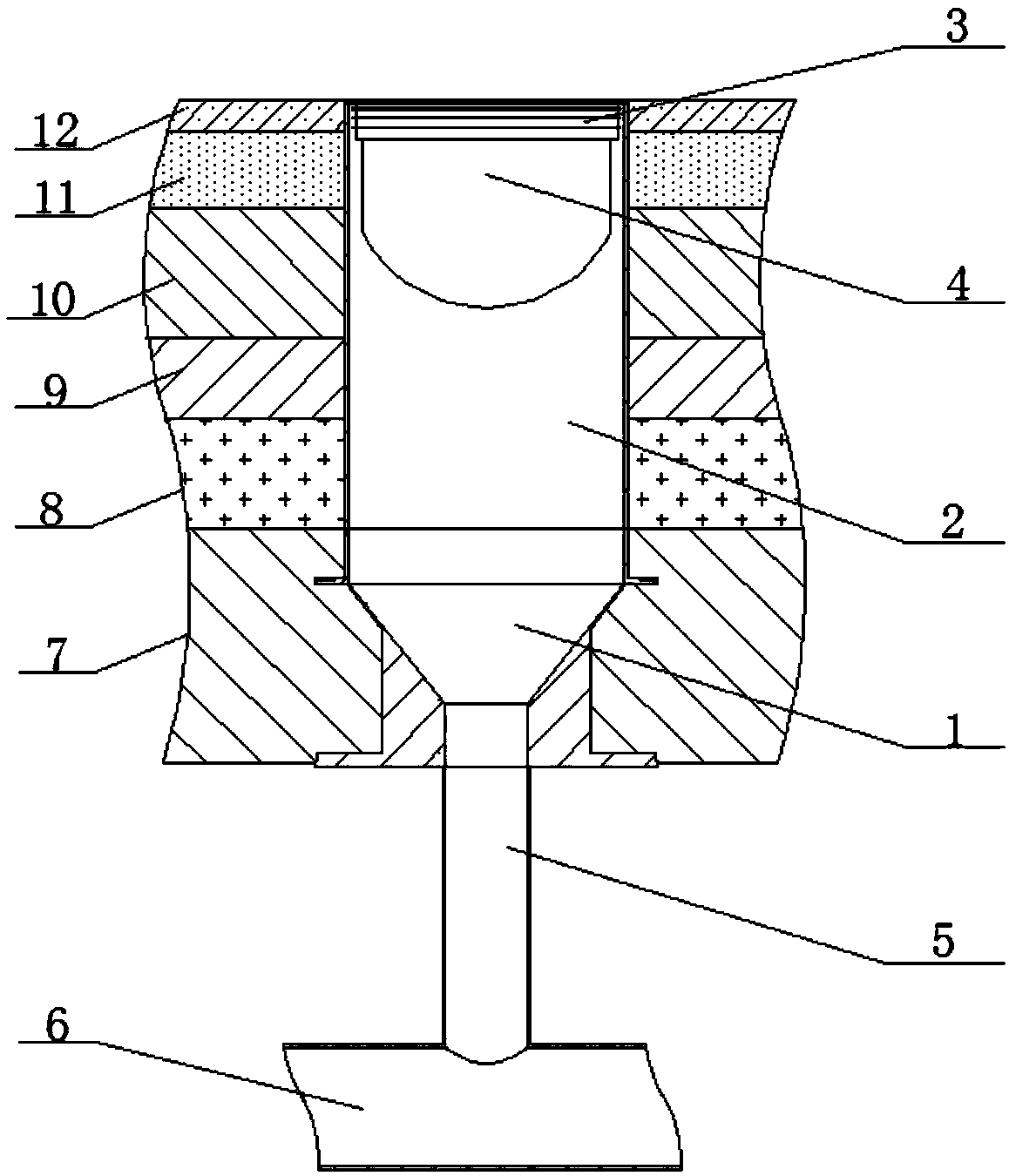

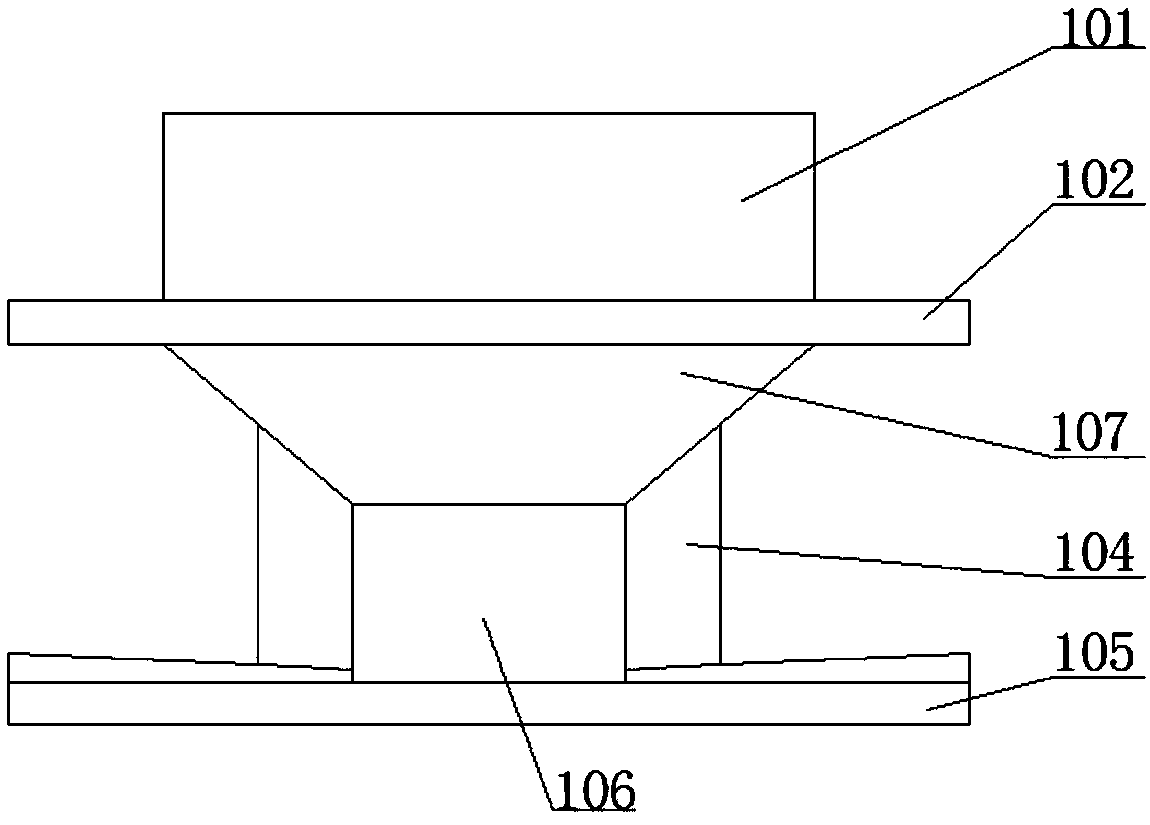

[0055] A floor drain connection device such as figure 1 and figure 2 As shown, it includes the water stop section 1 fixed on the formwork and poured together with the formwork and the floor steel frame. The water stop section 1 passes through the floor. The upper part of the water stop section 1 communicates with the drain pipe 2, and the upper part of the drain pipe 2 connects with the floor drain The body 4 is connected. The floor slab is hoisted according to the design drawings during the project, and the floor slab is used to locate the water stop section 1.

[0056] Further, the upper part of the drain pipe 2 is connected to the floor drain body 4 through a sealing rubber pad 3, specifically, the sealing rubber pad 3 is an annular rubber pad.

[0057] Further, the lower part of the water stop section 1 communicates with the downspout 5 .

[0058] Further, the water stop section 1 is connected to the drain pipe 2 through a sealant, and the water stop section 1 is conne...

Embodiment 3

[0071] The comparison between Embodiment 1 and Embodiment 2 in terms of process, time, cost, perception and use effect is shown in Table 1:

[0072] The comparative table of table 1 embodiment 1 and embodiment 2

[0073]

[0074]

[0075]

[0076] According to the above table, the specific analysis is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com