Method for reinforcing underwater pier of bridge by using FRP pipe

A bridge pier and bridge technology, which is applied in the field of civil engineering, can solve problems such as the specific applicability of the difficult handling method for underwater environment construction operations, the long construction period of the enlarged section reinforcement method, and the inconvenience of large-scale regular maintenance, etc., to achieve reinforcement effects Excellent, shortened construction period, fast and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

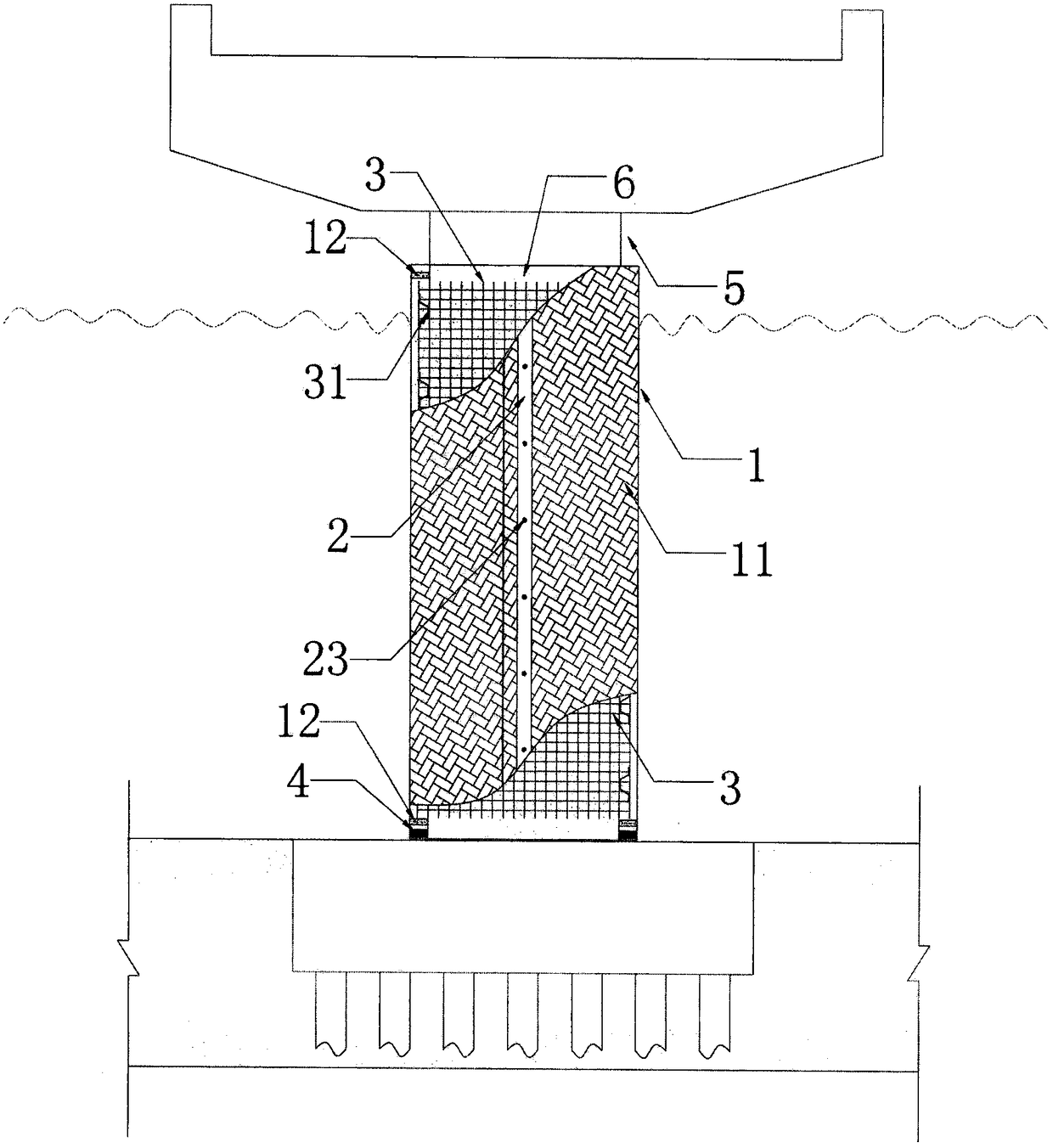

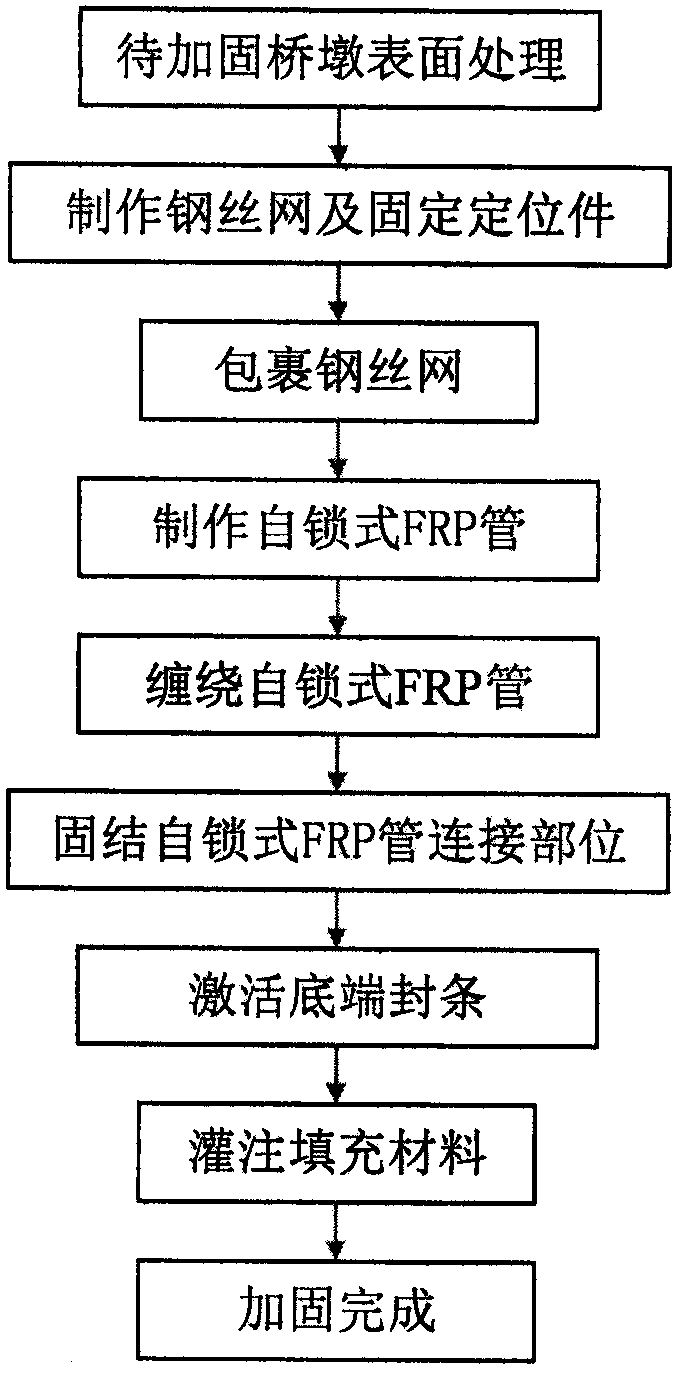

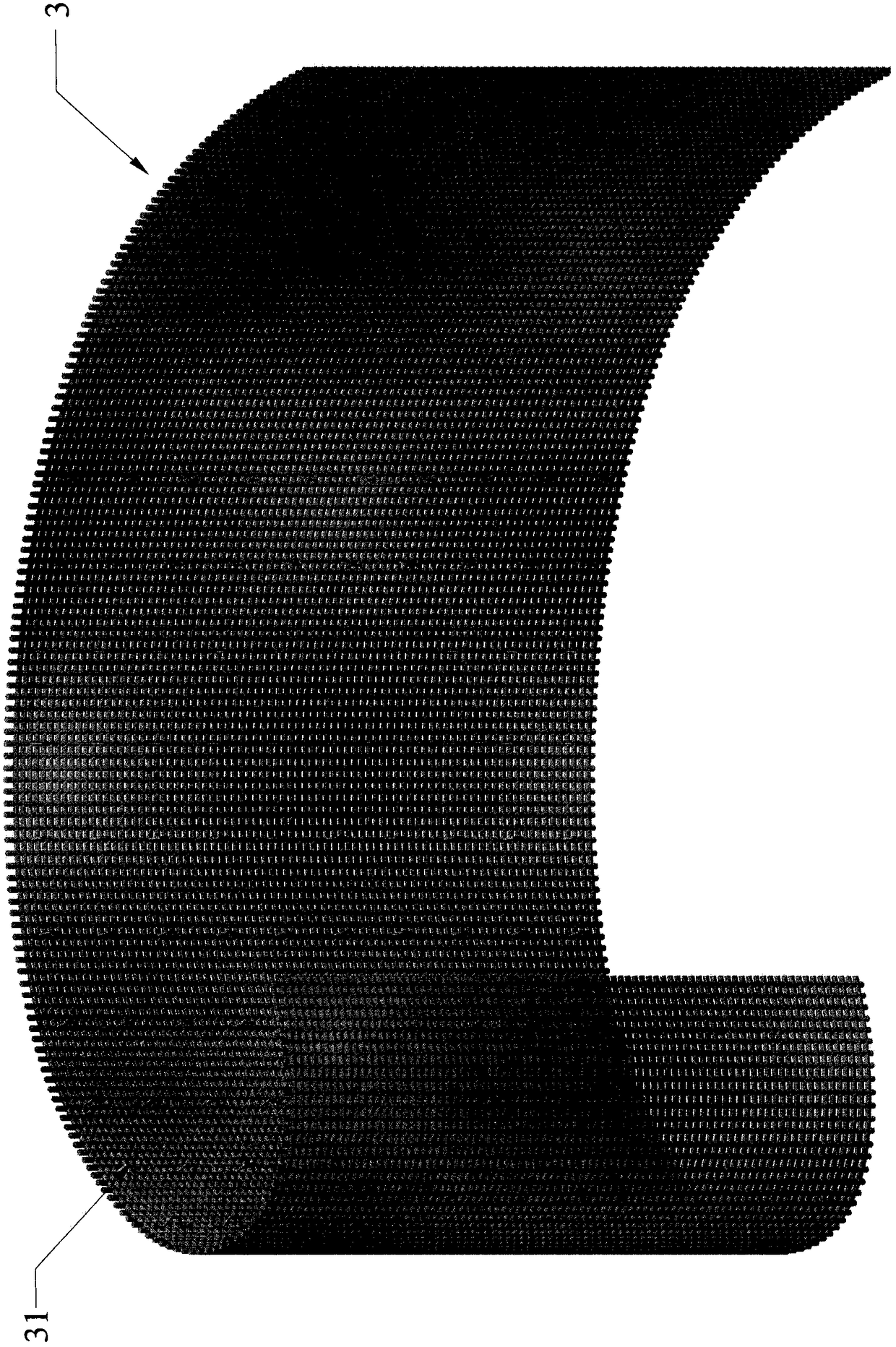

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides a method for reinforcing underwater piers of bridges with FRP pipes. By installing positioning parts 31, wrapping steel wire mesh 3, making self-locking FRP pipes 1, winding self-locking FRP pipes 1, and consolidating self-locking FRP pipes 1 Connecting parts, activating the bottom seal 4, pouring filling material 6 to realize the reinforcement of the underwater pier of the bridge, the self-locking FRP pipe 1 is provided with a limit pad 12, a movable clamp 2 and a bottom seal 4 to realize the underwater of the FRP pipe It is convenient to assemble, and the formwork and reinforcement materials are integrated to avoid drainage work; it is characterized in that the construction steps are as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com