Microalgae cell culture and collection integrated system and method

A microalgae cell and culture system technology, which is applied in the field of microalgae cell culture-harvesting integrated system, can solve the problems of large harvesting membrane device, large area of harvesting system, increased power consumption of harvesting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

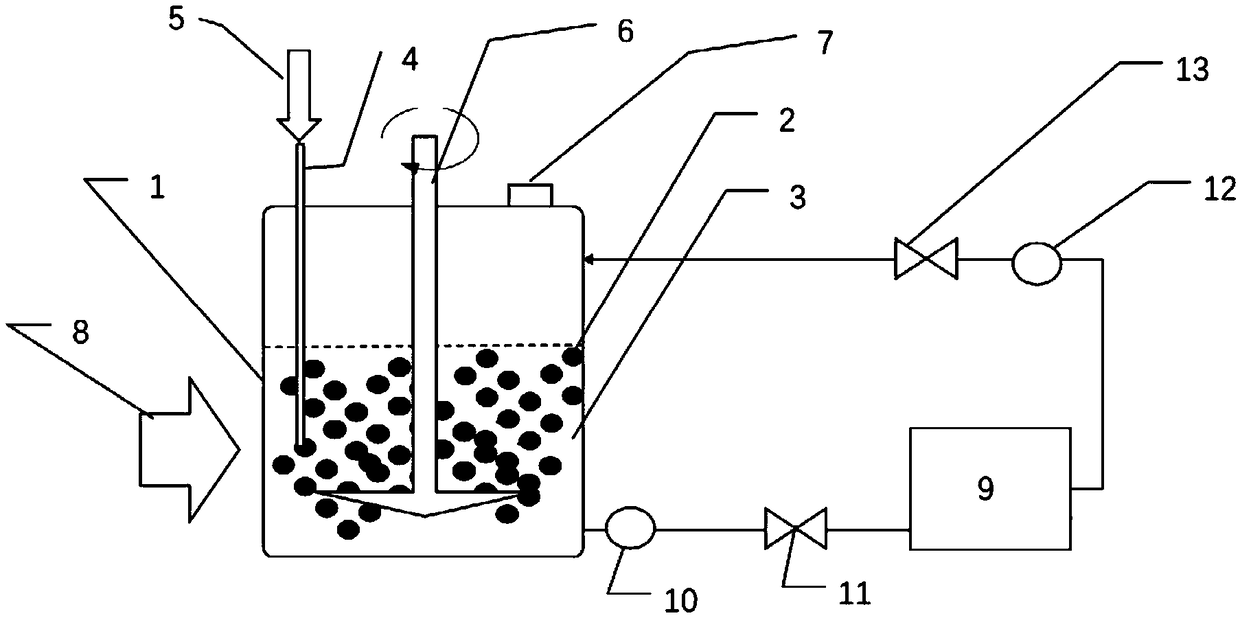

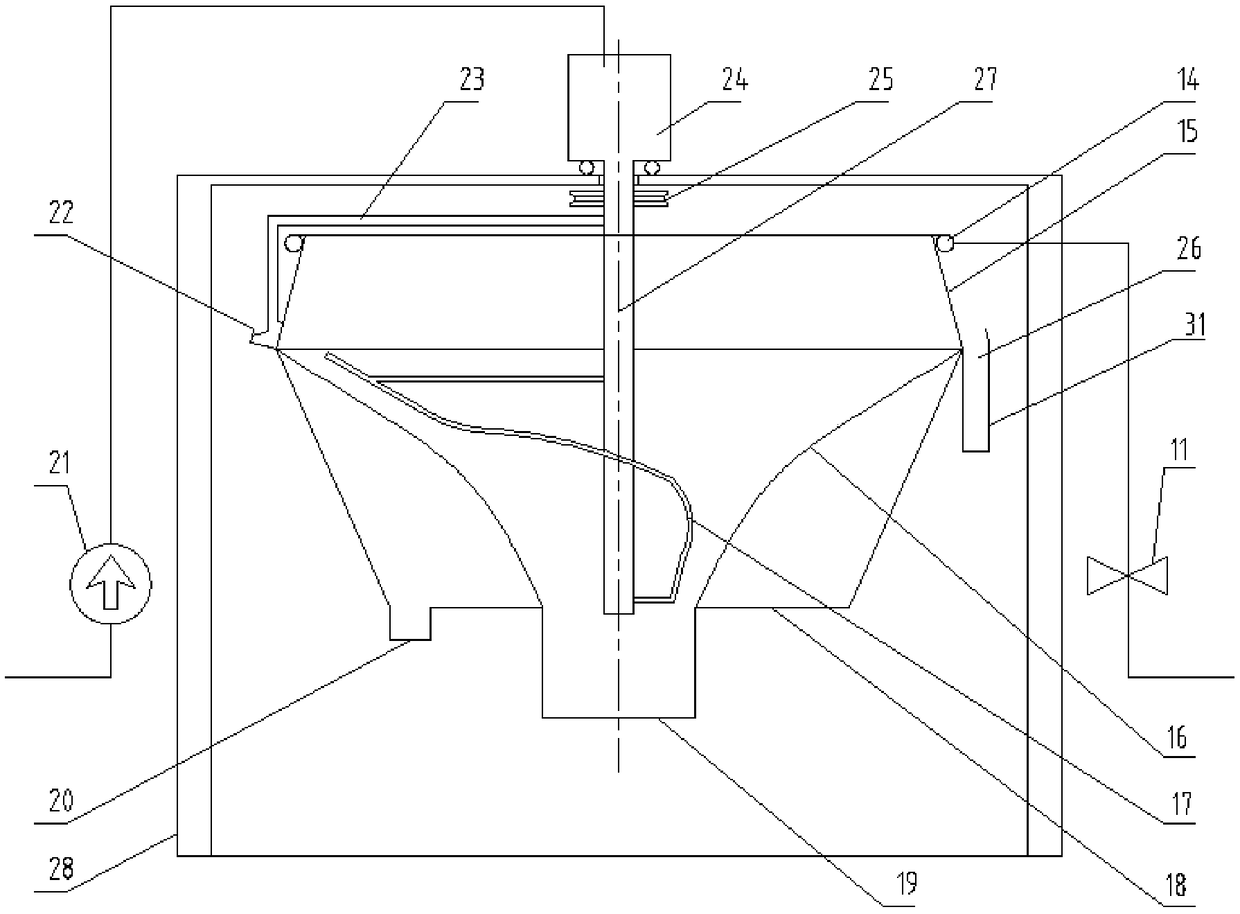

[0072] Such as Figure 1-5Shown, a kind of microalgae cell culture-harvesting integrated system comprises culture system, harvesting system 9, liquid delivery pump 10, liquid inlet valve 11, backflow pump 12, liquid outlet valve 13; Described culture system uses For the cultivation of algae cells, the harvesting system 9 is used to separate microalgae cells and culture fluid.

[0073] The culture system includes: a photoreactor 1 , an air inlet pipe 4 , an agitator 6 , an exhaust port 7 , and a light source 8 .

[0074] The microalgae cells 2 and the culture solution 3 are mixed together and located in the photoreactor 1. The photoreactor 1 is cylindrical. The source is connected, and the carbon-containing source gas 5 enters the culture solution 3 through the inlet pipe 4 to provide carbon elements for the photosynthetic growth of microalgae cells.

[0075] The agitator 6 is arranged in the photoreactor 1 , the exhaust port 7 is arranged on the upper part of the culture med...

Embodiment 2

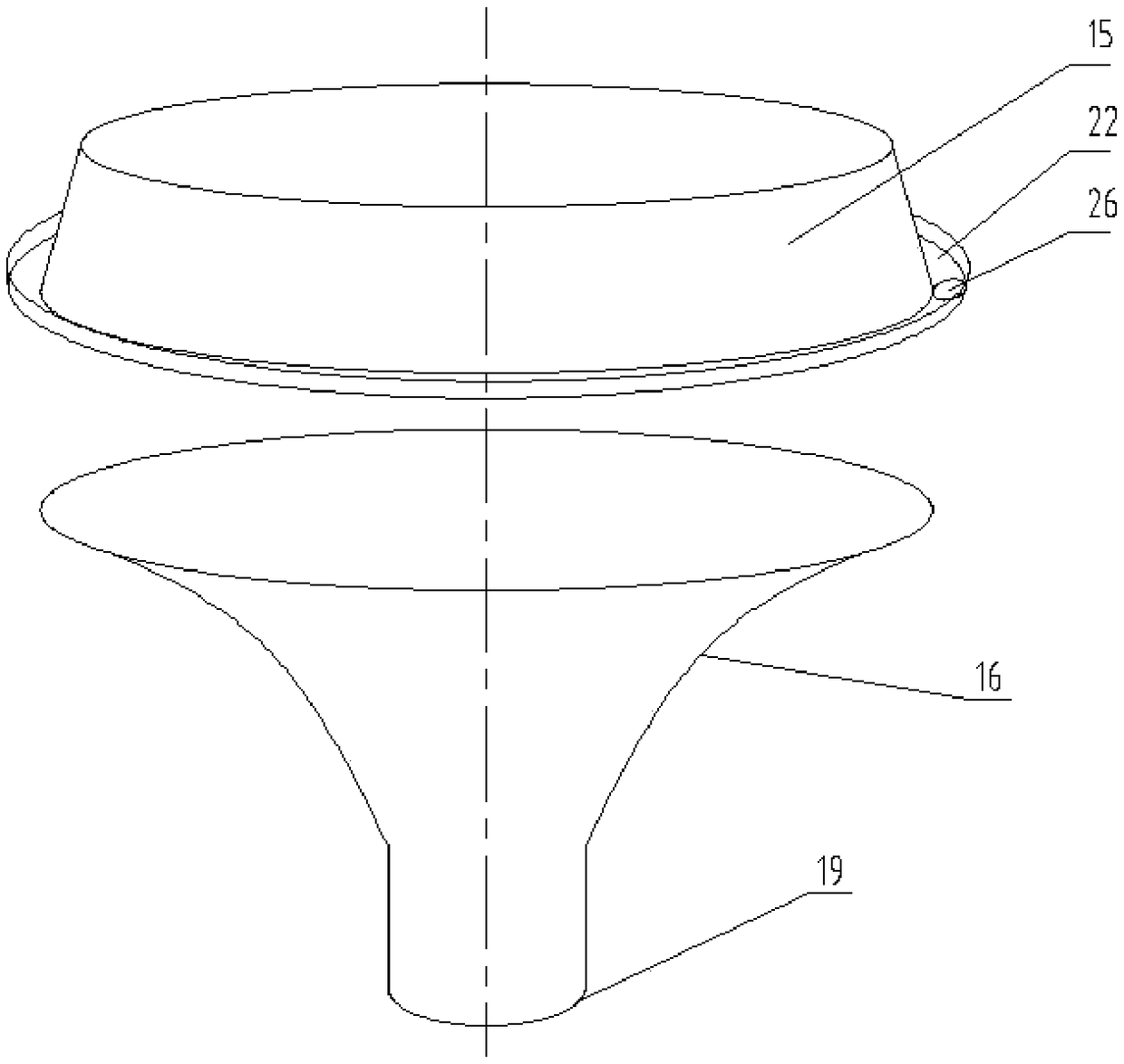

[0086] A microalgae harvesting system, the same as in Example 1, differs in that: (1) the bed surface of the filter residue bed 15 is made of a hard membrane material with membrane pores of 80 mesh.

[0087] (2) The bed surface of the recovery bed 16 is made of a soft filter cloth with membrane holes of 100 mesh.

[0088] (3) The gradient change of the inclination angle α of the bed surface of the recovery bed 16 relative to the horizontal plane is divided into 4 gradients, followed by α 1 =5°, α 2 =15°, α 3 = 45°, α 4 =85°.

Embodiment 3

[0090] An integrated system for cultivating and harvesting microalgae cells is the same as in Example 1, the difference is that: (1) the bed surface of the filter residue bed 15 is made of a hard membrane material with a membrane hole of 30 meshes.

[0091] (2) The bed surface of the recovery bed 16 is made of soft filter cloth with membrane holes of 400 mesh.

[0092] (3) The jet flow direction of the water spray holes on the cleaning water spray pipe 17 is at an angle of 90° to the flow direction of the algae mud. The light source 8 is natural sunlight.

[0093] (4) The dynamic sealing part 29 is a dynamic sealing structure of a mechanical seal.

[0094] (5) The integrated design of the inlet pipe and the agitator: the agitator is provided with an inlet pipe and an air outlet, and the carbon-containing source gas 5 enters the culture solution 3 through the air outlet after passing through the inlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com