Magnesium hydroxide-calcium alginate composite fire retardant and preparation method thereof

A composite flame retardant, calcium alginate technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of unsatisfactory product thermal decomposition temperature, cumbersome and complicated process, and limited flame-retardant effect, so as to achieve green and environmentally friendly materials and simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete steps of preparation are:

[0030] In step 1, the dolomite ore powder is calcined at 900° C. for 3 hours; wherein, the particle size of the dolomite ore powder is 0.1 mm to obtain dolomite lime powder. Then, according to the solid-to-liquid ratio of 1g:5ml, dolomite lime powder was added to water at 20°C and stirred for 60 minutes to obtain digestive juice.

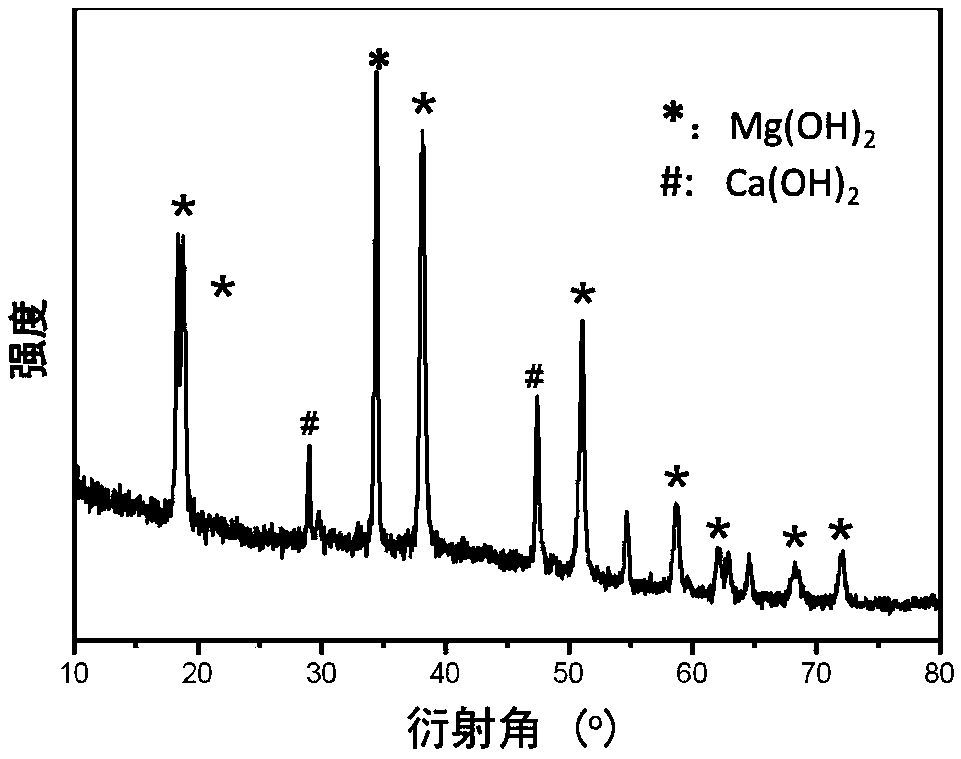

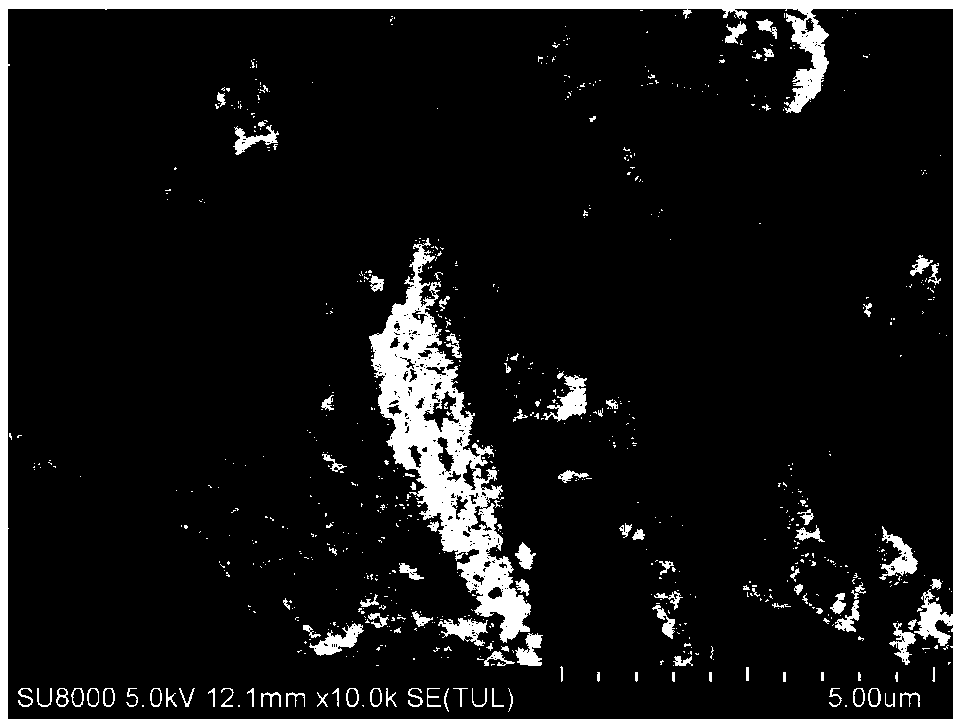

[0031] Step 2: First, according to the volume ratio of 1wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:5, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 20°C, and stir and foam for 10 minutes to obtain foam bubble gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming drying and setting treatment, and the temperature during the drying and setting treatment is 40° C. made as figure 1 As shown in the curves in , and approximated by figure 2 The magnesium hydroxi...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] In step 1, the dolomite ore powder is calcined at 925° C. for 2.5 hours; wherein, the particle size of the dolomite ore powder is 1 mm to obtain dolomite lime powder. Then, according to the solid-to-liquid ratio of 1 g: 17 ml, the dolomite lime powder was added into water at 38° C. and stirred for 53 minutes to obtain a digestive juice.

[0035] Step 2: First, according to the volume ratio of 3.3wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:4, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 38°C, and stir and foam for 23 minutes to obtain Foaming gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming and drying and setting treatment, and the temperature during the drying and setting treatment is 50° C. made as figure 1 As shown in the curves in , and approximated by figure 2 The m...

Embodiment 3

[0037] The concrete steps of preparation are:

[0038] In step 1, the dolomite ore powder is calcined at 950° C. for 2 hours; wherein, the particle size of the dolomite ore powder is 4 mm to obtain dolomite lime powder. Then according to the solid-to-liquid ratio of 1g:28ml, dolomite lime powder was added to water at 56°C and stirred for 45 minutes to obtain digestive juice.

[0039] Step 2: First, according to the volume ratio of 5.5wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:3, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 56°C, and stir and foam for 35 minutes to obtain Foaming gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming and drying and setting treatment, and the temperature during the drying and setting treatment is 60° C. made as figure 1 As shown in the curves in , and as figure 2 The magnesium hydroxide-calcium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com