Conductive polyphenylene sulfide resin, preparation method thereof and power battery

A polyphenylene sulfide resin and polyphenylene sulfide technology, which is applied in the field of new energy vehicle batteries, can solve the problems of inability to ensure the use performance of power batteries, current fluctuations, and large changes in the resistance value of power batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of conductive polyphenylene sulfide resin, comprising the following steps:

[0044] In terms of mass fraction, mix 25-60% polyphenylene sulfide, 15-40% silicate glass fiber, 5-40% calcium carbonate, 0.1-1% carbon black and 1-15% carbon fiber , and perform injection molding to obtain conductive polyphenylene sulfide resin.

[0045] In the present invention, the types, sources and amounts of the various raw materials are consistent with the types, sources and amounts of the various raw materials mentioned above, and will not be repeated here.

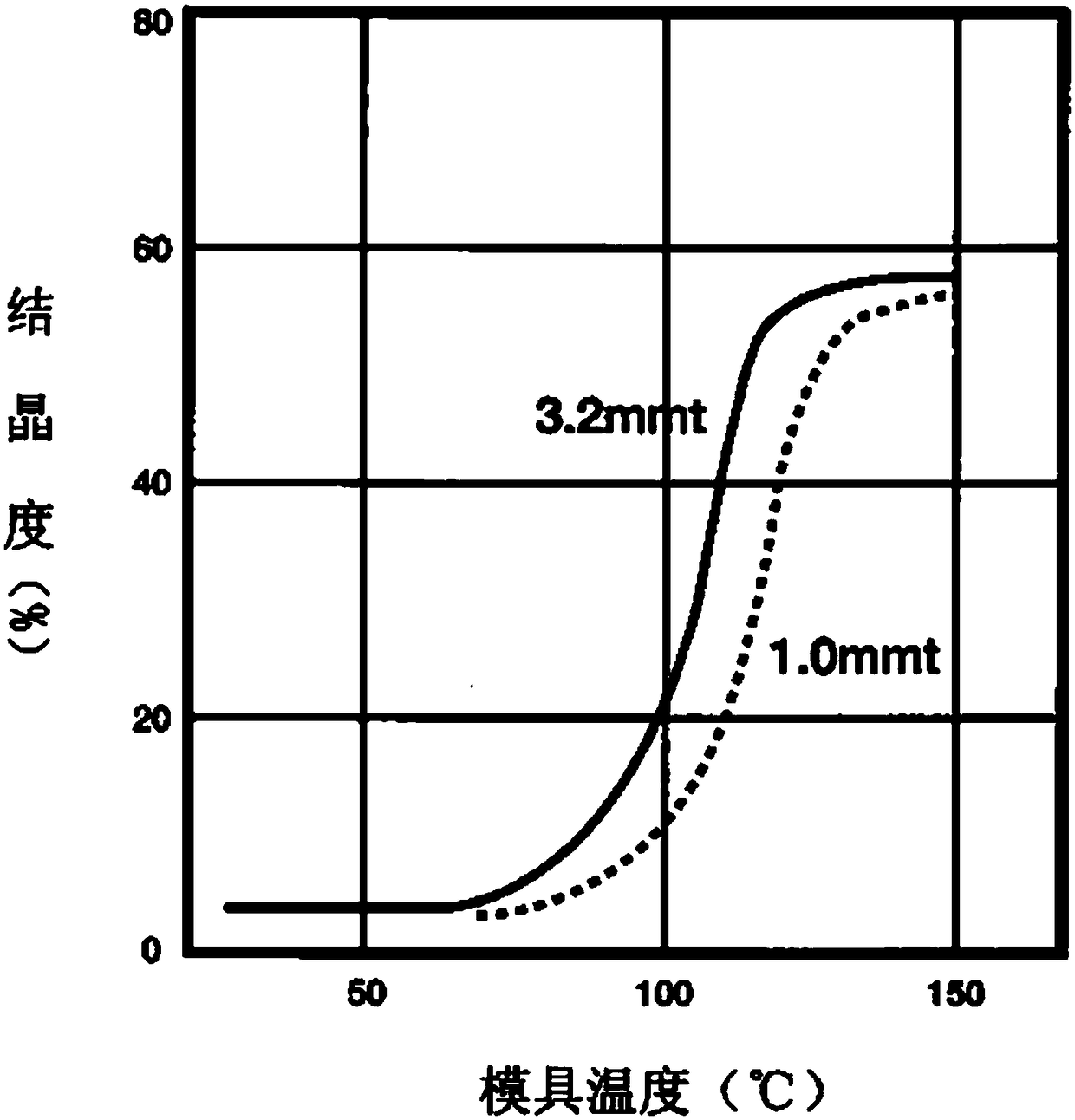

[0046] In the present invention, the temperature of the mold used in the injection molding is preferably 130-150°C, more preferably 140°C; the temperature of the four stages of the barrel in the injection molding is set as follows: the first stage: 290-300°C; The second stage: 300-320°C; the third stage: 310-330°C; the fourth stage: 310-330°C; the temperature of the nozzle i...

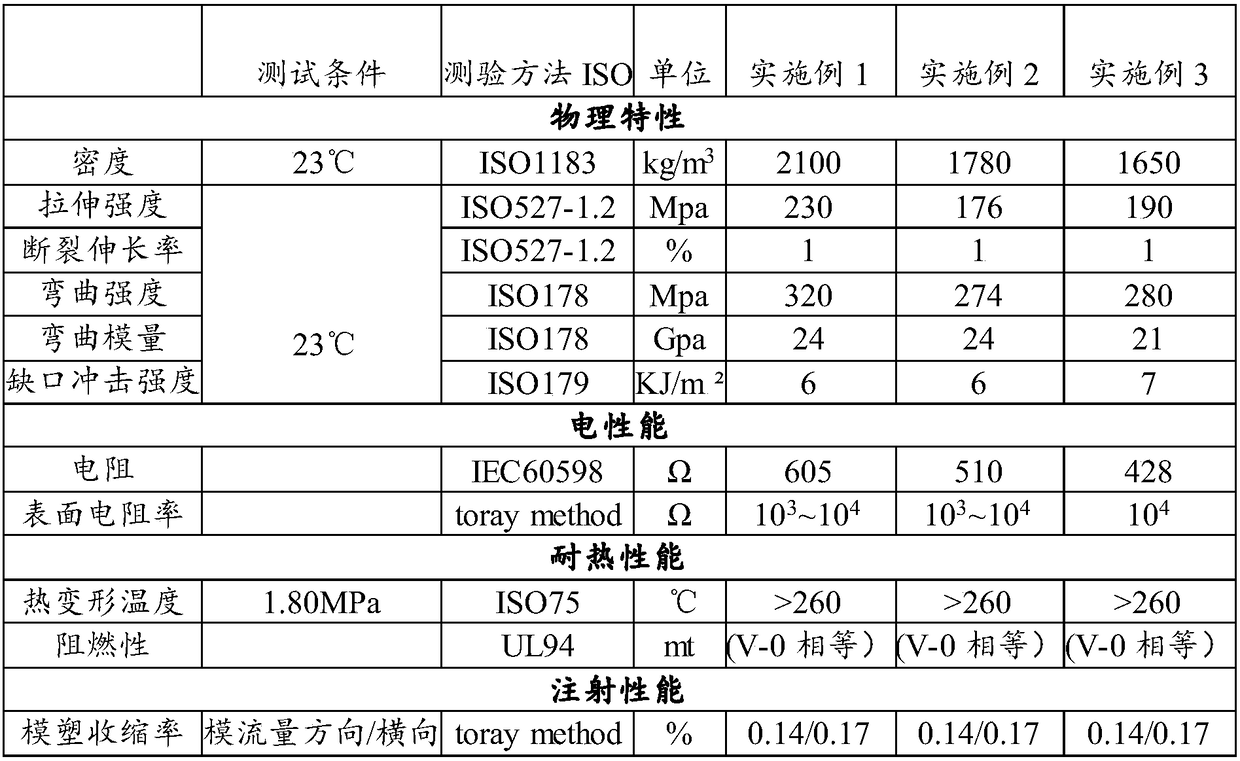

Embodiment 1

[0053] Mix the ingredients according to the following ratio:

[0054] Polyphenylene sulfide: 45%;

[0055] Silicate glass fiber: 35%;

[0056] Calcium carbonate: 10%;

[0057] Carbon black: 1%;

[0058] Carbon fiber: 9%;

[0059] Fill the obtained mixed raw material into the barrel, set the temperature of the fourth stage of the barrel, inject the mixed raw material into the mold through a nozzle at 310°C, the mold temperature is 130°C, and cool and shape the mold after filling to obtain a polyphenylene sulfide resin battery cover plate.

[0060] Among them, the temperature settings of the four stages of the barrel are as follows: the first stage: 290°C; the second stage: 300°C; the third stage: 310°C; the fourth stage: 310°C;

[0061] The injection molding pressure is 80MPa, and the speed is 40mm / s.

Embodiment 2

[0063] Mix the ingredients according to the following ratio:

[0064] Polyphenylene sulfide: 60%;

[0065] Silicate glass fiber: 25%;

[0066] Calcium carbonate: 10%;

[0067] Carbon black: 0.5%;

[0068] Carbon fiber: 14.5%;

[0069] Fill the obtained mixed raw material into the barrel, set the temperature of the fourth section of the barrel, inject the mixed raw material into the mold through a nozzle at 330°C, the mold temperature is 150°C, and cool and shape the mold after filling to obtain a polyphenylene sulfide resin battery cover plate.

[0070] Among them, the temperature setting of the four sections of the barrel is as follows: the first section: 300°C; the second section: 320°C; the third section: 330°C; the fourth section: 330°C;

[0071] The injection molding pressure is 150MPa, and the speed is 150mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com