An organic electroluminescence material and a preparing method thereof and an organic electroluminescent device

A technology of electroluminescent materials and luminescent materials, which is applied in the direction of luminescent materials, electric solid devices, electrical components, etc. It can solve the problems that the color coordinates cannot meet the requirements, it is not suitable for high-grade panels, and the color purity is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

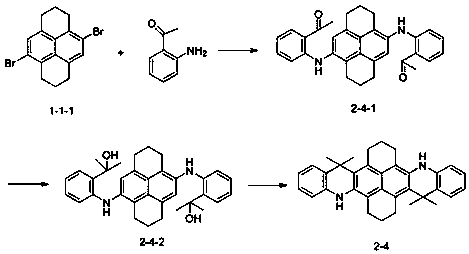

[0059] Synthesis of Intermediate 1-1

[0060]

[0061] Add 1,2,3,6,7,8-hexahydropyrene (10g, 48mmol), N-bromosuccinimide (21.4g, 120mmol), 250mL of dichloromethane and 250ml of acetonitrile into the reaction vessel and stir at room temperature 24 hours. After the reaction was completed, the solid was filtered under reduced pressure, and the obtained solid was washed with methanol to obtain intermediate [1-1-1] (12.3g, yield 70%). Mass spectrum: theoretical value 363, measured value 363.95.

[0062] Add intermediate [1-1-1] 22.00g (60.11mmol) to the reaction vessel under nitrogen gas, dissolve it in tetrahydrofuran (150mL), and add n-butyllithium (57.7mL, 144.28mmol) dropwise under nitrogen gas at -78°C and 16.2 ml (144.28 mmol) of trimethyl borate, and then stirred at room temperature for 3 hours. After the reaction was completed, HCl aqueous solution was added and the organic layer was extracted. The organic layer was dried and filtered with magnesium sulfate, concentra...

Embodiment 2

[0067] Synthesis of Intermediate 2-1

[0068]

[0069] Add intermediate 1-1 (5.8 g, 16.9 mmol), 2-bromo-nitrobenzene (3.7 g, 18.4 mmol), tetrakis(triphenylphosphine) palladium (0.7 g, 1.08 mmol), potassium carbonate ( 5.3 g, 38.3 mmol), toluene (60 mL), ethanol (20 mL) and distilled water (20 mL), stirred at 120°C for 3 hours. After the reaction was completed, it was washed with distilled water, and the organic layer was extracted with ethyl acetate. The extracted organic layer was dried over magnesium sulfate, and the solvent was distilled off under reduced pressure. Intermediate 2-1-1 (4.95 g, 65%) was obtained by column chromatography. Mass spectrum: theoretical value 450, measured value 450.16.

[0070] Compound 2-1-1 (35.1g, 78mmol) and triethyl phosphite (200ml) were added to o-dichlorobenzene (150ml), and stirred at 150°C for one day. The organic layer was extracted, and intermediate 2-1 (16.6 g, 55%) was purified by column chromatography, mass spectrum: theoretica...

Embodiment 3

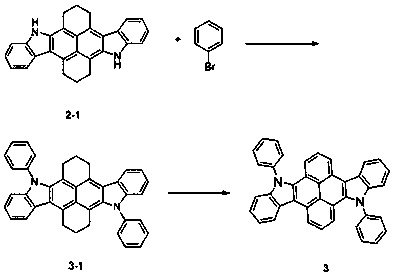

[0084] Synthesis of Example 3 Compounds

[0085] Synthesis of compound 3

[0086]

[0087] Under nitrogen, add intermediate 2-1 (13.4g, 34.72mmol), bromobenzene (5.45g, 34.72mmol) to the reaction vessel and cloud it with toluene (230ml), then add sodium tert-butoxide (10.01g, 104.16mmol ), palladium acetate (0.31g, 1.39mmol), and t-tri-tert-butylphosphine (1.12g, 2.78mmol) were then stirred at 80°C for 1 hour. After the reaction, 200ml of water was added, and the resulting solid was filtered under reduced pressure, washed twice with water, and dried to obtain gray intermediate 3-1 (16.2g, 86.8%), mass spectrum: theoretical value 538, measured value 538.24.

[0088] Add intermediate 3-1 (14.9g, 27.64mmol), 2,3-dichloro-5,6-dicyano-1,4-benzoquinone (7.53g, 33.2mmol), toluene (500mL) to the reaction vessel After stirring at 90°C for 3 hours, the reaction solution was cooled and then recrystallized to obtain the target compound 3 (12.96 g, yield 88%), mass spectrum: theoretic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com