Mold and method for injection molding of high-compression resistance and long-life notebook computer baseboard shell

A notebook computer, injection molding technology, used in household appliances, other household appliances, household components, etc., can solve the problems of long stroke and poor injection efficiency, and achieve the effect of high delivery rate, low manufacturing cost and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

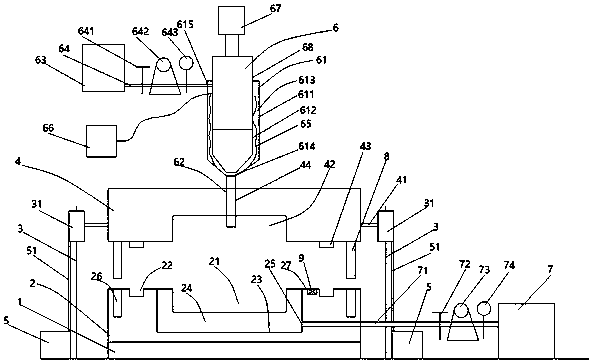

[0023] refer to figure 1, a high-pressure-resistant and long-life notebook computer chassis injection molding mold according to the present invention, the mold includes: a fixed template 1, which is placed horizontally; a fixed module 2, which is arranged on the fixed template 1 along the length direction of the fixed template 1 In the middle part of the upper surface, the middle part of the upper surface of the fixed module 2 is provided with a certain mold groove 21 along the vertical direction, and the upper surface of the fixed module 2 located outside the two ends of the width direction of the fixed mold groove 21 is respectively provided with a positioning groove 22 along the width direction of the fixed module 2; Two struts 3 are erected vertically and symmetrically on the outer sides of the two ends of the fixed formwork 1 in the length direction. The two struts 3 are respectively slidingly sleeved with a slider 31 at the position above the fixed module 2; the moving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com