A metal coil processing system and processing method

A processing system and technology for metal coils, which can be applied to household appliances, hollow objects, and other household appliances, etc., can solve the problems of low width precision at the rolling end and large fluctuations in the end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

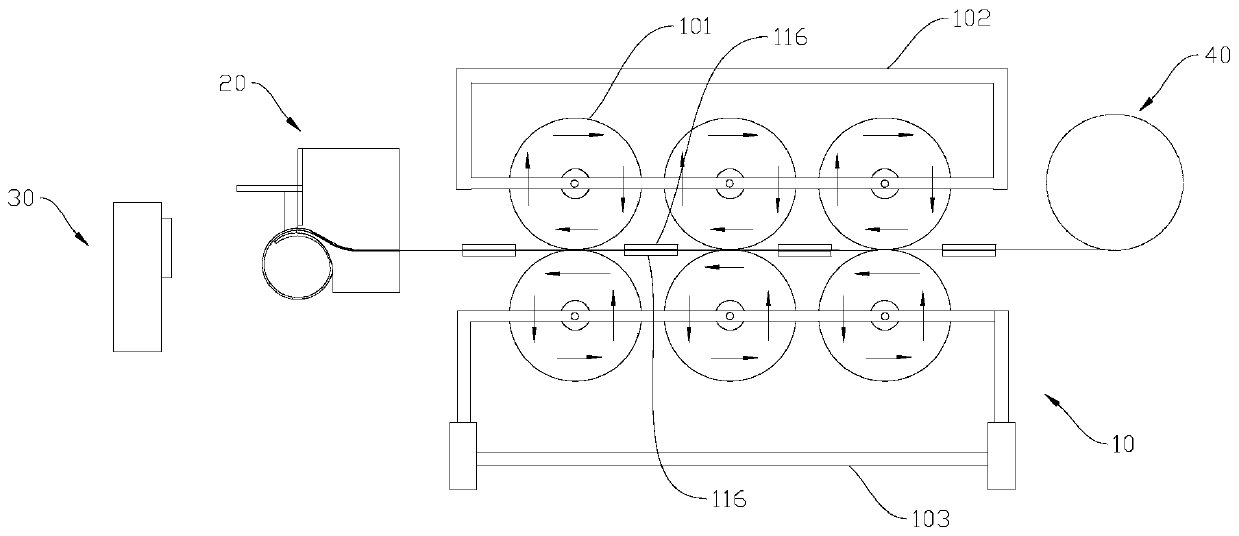

[0039] Please refer to figure 1 The metal coil processing system shown in the embodiment of the present invention includes: a shape correcting feeding device 10 , a forming device 20 and a cutting machine 30 . According to the production steps of shape correction, forming and material cutting, a shape correction feeding device 10, a forming device 20 and a material cutting machine 30 are arranged in sequence. Specifically, the feeding side of the shape-correcting feeding device 10 is set correspondingly to the coil material to be formed, and the discharging side of the shape-correcting feeding device 10 is set correspondingly to the feeding side of the forming device 20, so that the blank 40 after the shape-correcting is transported to Forming in the forming device 20. A material cutter 30 is provided on the discharge side of the molding device 20 . The cutting machine 30 of the present invention is preferably a laser cutting machine. Of course, other types of metal cutting...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, except that the shape of the third module 203 in this embodiment changes. Please refer to Figure 8, the sliding contact surface between the first module 201 and the third module 203 is a slope. The third module 203 slides obliquely upwards or downwards along the outer sidewall of the first module 201 while adjusting its position in the horizontal and vertical directions. The third module 203 includes a sliding surface 216 in contact with the first module 201 and a positioning surface 217 connected with the sliding surface 216 and located below the third module 203 . The positioning surface 217 corresponds to the forming channel 204 . A point on the positioning surface 217 is taken as the positioning point to realize three-point positioning, and the coil forming principle is the same as that in Embodiment 1. A slide rail 218 is provided on the slide surface 216 , and a third slide groove 219 matching with the sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com