Warm straightening method for pure titanium plate and low-strength titanium alloy plate

A titanium alloy plate, warm straightening technology, applied in the direction of metal processing equipment, forming tools, feeding devices, etc., can solve the problems of time-consuming and labor-intensive straightening process, uneven titanium plate, few straightening passes, etc., and achieve low efficiency , strong applicability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

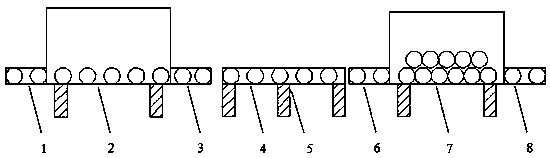

Image

Examples

Embodiment 1

[0019] Warm straightening of 6mm TA1 pure titanium plate according to the following process parameters:

[0020] Determine the straightening temperature T corresponding to the titanium alloy plate according to the 6mm TA1 pure titanium plate 0 100~500℃, the annealing temperature T corresponding to the titanium alloy plate to be straightened 1 700~780℃, the annealing and holding time t is 35~50min, and calculate the speed V of the titanium alloy plate to be straightened into the annealing furnace 1 , V 1 =0.2~1m / min, at the same time determine the distance between two adjacent titanium alloy plates to be straightened as L 间 , L 间 =1m, V 3 =1~3m / min through the connecting roller table at the same time with V 3 =1~3m / min Automatic unloading through the exit roller table of the straightener;

[0021] Then pre-heat the roller hearth heating furnace to 700~780°C, and the 6*1030~1280*2500~5500mm TA1 pure titanium plate enters the roller bottom through the roller hearth annealin...

Embodiment 2

[0023] Temperature straightening of 4~10mm Ti70 titanium alloy plate according to the following process parameters:

[0024] Determine the straightening temperature T corresponding to the titanium alloy plate according to the 4~10mm Ti70 titanium alloy plate 0 ≥300℃, the annealing temperature T corresponding to the titanium alloy plate to be straightened 1 600~750℃, the annealing heat preservation time t is 30~55min, and calculate the speed V of the titanium alloy plate to be straightened into the annealing furnace 1 , V 1 =0.2~1m / min, at the same time determine the distance between two adjacent titanium alloy plates to be straightened as L 间 , L 间 =0.5~1m, V 3 =3m / min through the connecting roller table at the same time with V 3 =3m / min automatic unloading through the exit roller table of the straightener;

[0025] Pre-heat the roller hearth heating furnace to 600~750℃, and the Ti70 titanium alloy plate with a size of 4~10*800~1250*2000~4000mm passes through the roller he...

Embodiment 3

[0027] Warm straightening of 4~10mm TA5 titanium alloy plate according to the following process parameters:

[0028] Determine the straightening temperature T corresponding to the titanium alloy plate according to the 4~10mm TA5 titanium alloy plate 0 ≥300℃, the annealing temperature T corresponding to the titanium alloy plate to be straightened 1 600~700℃, the annealing and holding time t is 30~55min, and calculate the speed V of the titanium alloy plate to be straightened into the annealing furnace 1 , V 1 =0.2~1m / min, at the same time determine the distance between two adjacent titanium alloy plates to be straightened as L 间 , L 间 =0.5~1m, V 3 =3m / min through the connecting roller table at the same time with V 3 =3m / min automatic unloading through the exit roller table of the straightener;

[0029] Pre-heat the roller hearth heating furnace to 600~700℃, and the TA5 titanium alloy plate with a size of 4~10*800~1250*2000~4000mm passes through the roller hearth annealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com