Acetic acid rectifying tower with built-in condenser and built-in reboiler

A technology of acetic acid distillation tower and condenser, which is applied in the field of acetic acid preparation equipment, can solve problems such as low efficiency and long reaction cycle time, and achieve the effect of ensuring reaction, reducing reaction cycle time, and ensuring sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

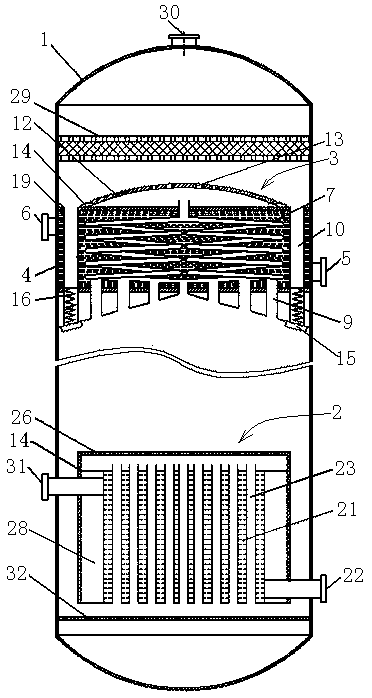

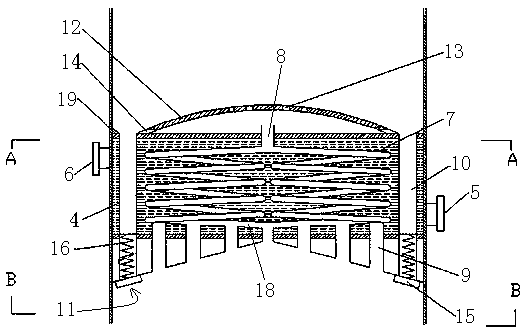

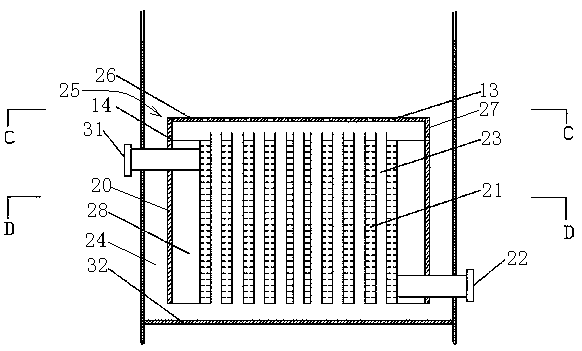

[0027] Such as Figures 1 to 7 An acetic acid rectification tower with a built-in condenser and reboiler is shown, including a tower body, and a reboiler 2 and a condenser 3 are arranged in the tower body 1 sequentially from bottom to top. The main body of the condenser 3 is a cylindrical box 4 filled with cooling water. The cylindrical box 4 is connected with a cooling water inlet 5 and a cooling water outlet 6 protruding from the outside of the tower. The cooling water inlet 5 is located in the cylindrical box. The lower right of the cooling water outlet 6 is at the upper left of the cylindrical box. The steam pipe 7 is spirally distributed from bottom to top in the cylindrical box 4, and the spiral distribution can increase the contact area with the cooling water, so that the internal gas can be fully cooled.

[0028] The steam pipeline 7 has a gas phase outlet 8 and the gas phase outlet 8 is located in the middle of the upper end plate of the cylindrical box body 4. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com