Preparation method of high-dietary fiber drawing protein

A technology with high dietary fiber and silky protein, which is applied in the field of food processing, can solve the problem that bean dregs cannot be eaten directly, and achieve the effect of good molding effect, high dietary fiber content, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

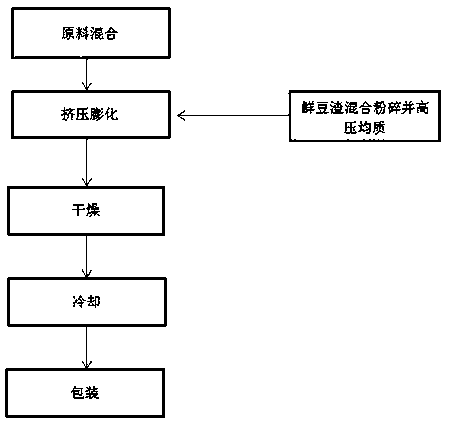

Image

Examples

preparation example Construction

[0032] A preparation method of high dietary fiber drawing protein, its raw material composition is (mass percentage):

[0033] Soy protein isolate 5%-20%,

[0034] Soy protein concentrate 25%-45%,

[0035] Low temperature defatted soybean meal 10%-20%,

[0036] Wheat starch 4%-8%,

[0037] Gluten 20%-35%,

[0038] Fresh bean dregs 5%-15%,

[0039] water;

[0040] Its production steps are:

[0041] 1) Fresh bean dregs and water are mixed in a mixing tank according to the mass ratio of 1:4. The mixing time is 15-20 minutes. The bean dregs are fully swollen, and then pulverized by a colloid mill.

[0042] 2) Soybean protein isolate, soybean protein concentrate, right 4 low-temperature defatted soybean meal, wheat starch, and gluten powder are put into the mixer according to the proportion of raw materials, and the mixing time is 15 minutes. Strictly control the time. If the time is too long, it will damage the structure of raw materials. extrusion puffing effect;

[0043]...

Embodiment 1

[0057] Take 50kg of low-temperature defatted soybean meal with a particle size of 30% through a 100 mesh sieve after crushing, 115kg of concentrated soybean protein, 90kg of gluten powder, 30kg of isolated soybean protein, and 15kg of starch, and put them into the mixing tank in turn, start stirring and mixing for 15 minutes, and strictly control the mixing time. If the time is too long, the tissue structure of raw materials will be destroyed and the extrusion effect will be affected. The mixed materials will be temporarily stored in the raw material bin.

[0058] The soybean dregs newly produced by the soybean protein isolate workshop are weighed and transported to the mixing tank, and at the same time, 4 times of water is added. The water temperature is required to be 25-30°C, and the mixing is carried out for 15 minutes. High-pressure homogenizer, the homogenization pressure is 20-30Mpa, after homogenization, it is transported to the mixing tank for temporary storage, and th...

Embodiment 2

[0062] Take 30kg of crushed 100-mesh sieve with a particle size of 40% and low-temperature defatted soybean meal, 135kg of concentrated soybean protein, 60kg of gluten powder, 60kg of isolated soybean protein, and 15kg of starch, and put them into the mixing tank in turn, start stirring and mixing for 15 minutes, and strictly control the mixing time.

[0063]20kg of bean dregs newly produced by the soybean protein isolate workshop are transported to the mixing tank, and 4 times the water is added at the same time. Homogenizing machine, the homogenizing pressure is 25Mpa, after homogenizing, it is transported to the stirring tank for temporary storage, and the stirring speed is 300 rpm.

[0064] The uniformly mixed material is quantitatively sent to the twin-screw extrusion extruder, and at the same time, the homogenized fresh bean dregs suspension is quantitatively injected into the mixing area of the extruder for extrusion and expansion. The added amount of the bean dregs su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com